Information injection-pump assembly

ZEXEL

101603-0771

1016030771

ISUZU

1156018571

1156018571

Rating:

Cross reference number

ZEXEL

101603-0771

1016030771

ISUZU

1156018571

1156018571

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.6

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

76.8

75.2

78.4

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

260

260

260

Average injection quantity

mm3/st.

8.1

6.8

9.4

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.6)

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

76.8

75.8

77.8

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

I

Rack position

15.3+-0.

5

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

92

92

100

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1350--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1300

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1400

Advance angle

deg.

2

1.5

2.5

Timer adjustment_04

Pump speed

r/min

1500

Advance angle

deg.

4.5

4

5

Remarks

Finish

Finish

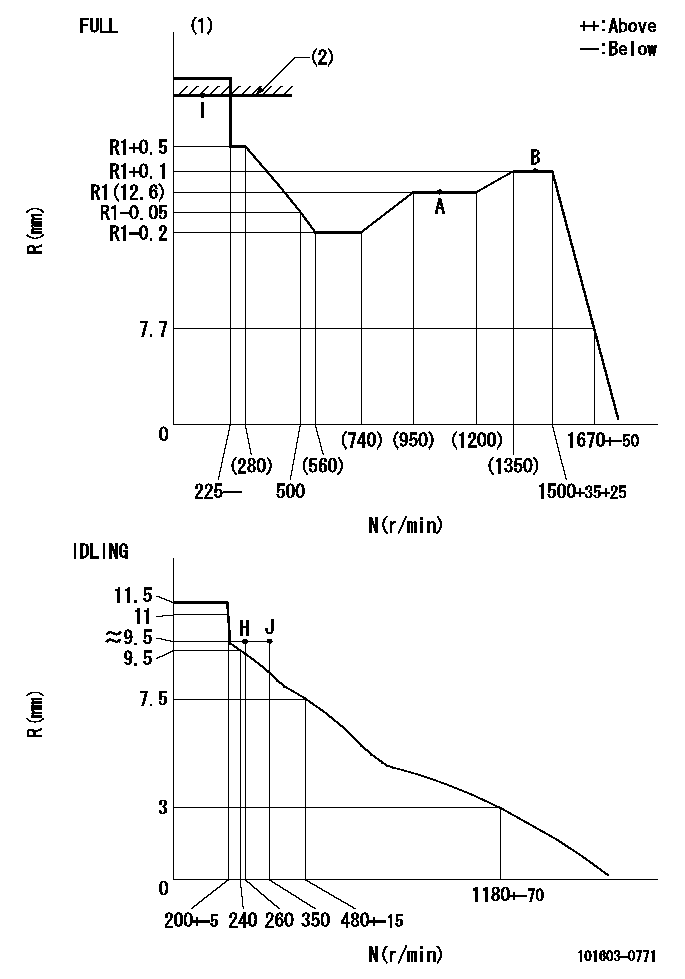

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

----------

T1=C32

----------

----------

T1=C32

----------

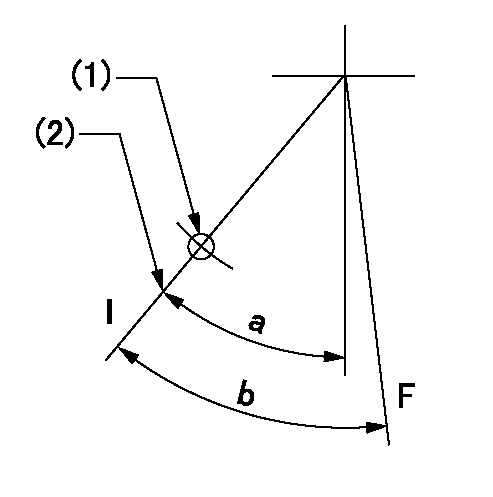

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=45mm

----------

a=21.5deg+-5deg b=(43deg)+-3deg

----------

aa=45mm

----------

a=21.5deg+-5deg b=(43deg)+-3deg

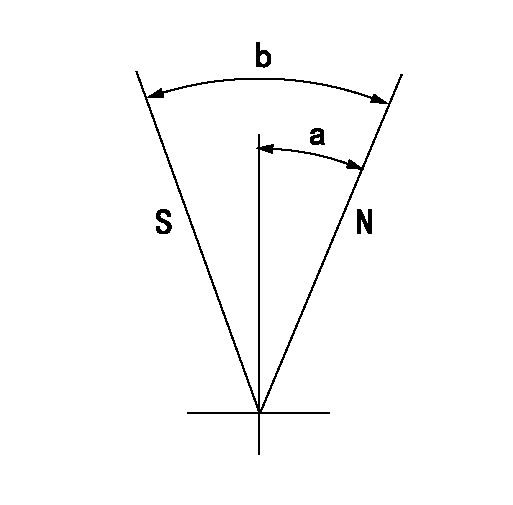

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=25deg+-5deg b=40deg+-5deg

----------

----------

a=25deg+-5deg b=40deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(60deg)

----------

aa=12deg

----------

a=(60deg)

Information:

1. Remove tube and elbow (1).2. Remove tube and oil sump (2). 3. Turn the crankshaft until two of the pistons are at top center and two are at bottom center.

Put identification marks on the connecting rod caps as to their location in the engine. Keep the caps with their respective piston.

4. Remove nuts (3), and remove connecting rod bearing cap (4).5. Remove the lower bearing half from the connecting rod cap. Push the connecting rod away from the crankshaft, and remove the upper bearing half.

Use tape to hold the bearing halves together and to identify the number of the cylinder.

6. Install the upper bearings in the connecting rods. Be sure the tab on the back of the bearing fits in the groove of the connecting rod. Install the connecting rod bearings dry when the clearance checks are made. Put clean engine oil on the connecting rod bearings for final assembly.7. Carefully pull the connecting rods onto the crankshaft.8. Install the lower bearings in the connecting rod caps. Be sure the tab on the back of the bearing fits the groove of the cap.9. Check the bearing clearance with Plastigage as follows:a. Put clean oil on the connecting rod bolt threads.b. Align the number on bearing cap (4) with the number on the connecting rod, and install bearing cap (4) with a line of Plastigage across the bearing.c. Install the nuts finger tight; then tighten them to a torque of 100 N m (75 lb.ft.).d. Remove the connecting rod cap, and measure the thickness of the Plastigage to the bearing clearances. See Engine Specifications for correct bearing clearances.e. Carefully move the connecting rod up enough to permit clean engine oil to be put on the upper bearing and crankshaft journal.f. Carefully pull the connecting rod onto the crankshaft.g. Install connecting rod cap (4), and tighten the nuts to the proper torque. The Cadmium plated nuts (silver color) are to be tightened to a torque of 100 N m (75 lb.ft.). The Phosphated nuts (dull black color) are to be tightened to a torque of 130 N m (95 lb.ft.).h. Repeat the procedure for the remainder of the connecting rods.10. Install tube and elbow (1) and tube and oil sump (2).End By:a. install oil pan

Put identification marks on the connecting rod caps as to their location in the engine. Keep the caps with their respective piston.

4. Remove nuts (3), and remove connecting rod bearing cap (4).5. Remove the lower bearing half from the connecting rod cap. Push the connecting rod away from the crankshaft, and remove the upper bearing half.

Use tape to hold the bearing halves together and to identify the number of the cylinder.

6. Install the upper bearings in the connecting rods. Be sure the tab on the back of the bearing fits in the groove of the connecting rod. Install the connecting rod bearings dry when the clearance checks are made. Put clean engine oil on the connecting rod bearings for final assembly.7. Carefully pull the connecting rods onto the crankshaft.8. Install the lower bearings in the connecting rod caps. Be sure the tab on the back of the bearing fits the groove of the cap.9. Check the bearing clearance with Plastigage as follows:a. Put clean oil on the connecting rod bolt threads.b. Align the number on bearing cap (4) with the number on the connecting rod, and install bearing cap (4) with a line of Plastigage across the bearing.c. Install the nuts finger tight; then tighten them to a torque of 100 N m (75 lb.ft.).d. Remove the connecting rod cap, and measure the thickness of the Plastigage to the bearing clearances. See Engine Specifications for correct bearing clearances.e. Carefully move the connecting rod up enough to permit clean engine oil to be put on the upper bearing and crankshaft journal.f. Carefully pull the connecting rod onto the crankshaft.g. Install connecting rod cap (4), and tighten the nuts to the proper torque. The Cadmium plated nuts (silver color) are to be tightened to a torque of 100 N m (75 lb.ft.). The Phosphated nuts (dull black color) are to be tightened to a torque of 130 N m (95 lb.ft.).h. Repeat the procedure for the remainder of the connecting rods.10. Install tube and elbow (1) and tube and oil sump (2).End By:a. install oil pan