Information injection-pump assembly

ZEXEL

101603-0540

1016030540

ISUZU

1156014391

1156014391

Rating:

Service parts 101603-0540 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

18.1(185)

15.

NOZZLE SET

Cross reference number

ZEXEL

101603-0540

1016030540

ISUZU

1156014391

1156014391

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

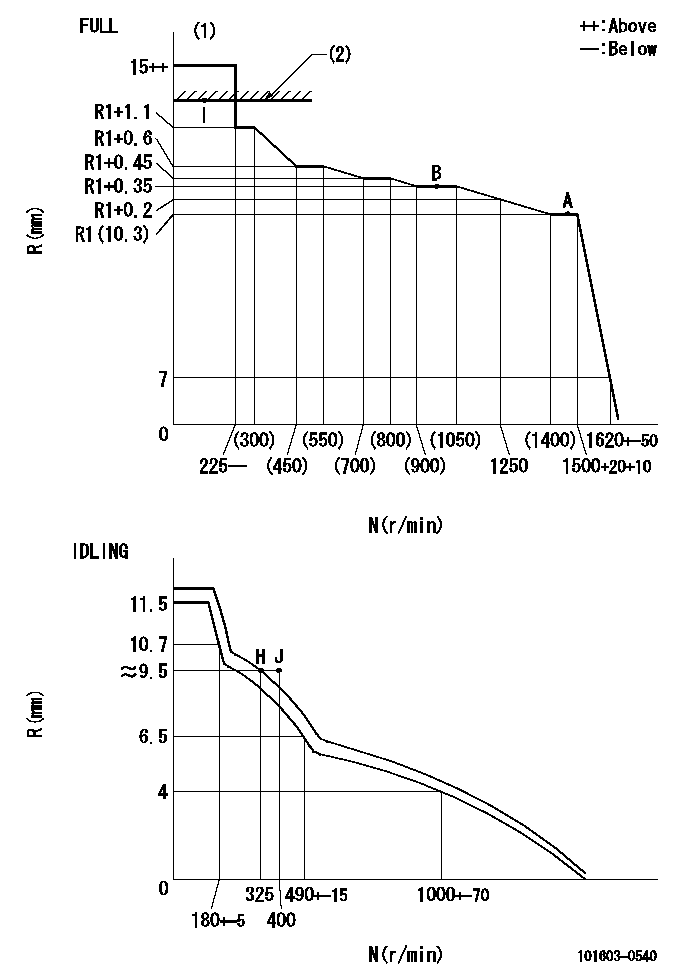

Injection quantity adjustment

Adjusting point

-

Rack position

10.3

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

48.9

47.3

50.5

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

8.7

7.4

10

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(10.3)

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

48.9

47.9

49.9

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.35

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

54.3

51.1

57.5

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

60

65

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

350--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

300

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

2

1.5

2.5

Timer adjustment_04

Pump speed

r/min

1500

Advance angle

deg.

4

3.5

4.5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

----------

T1=B08

----------

----------

T1=B08

----------

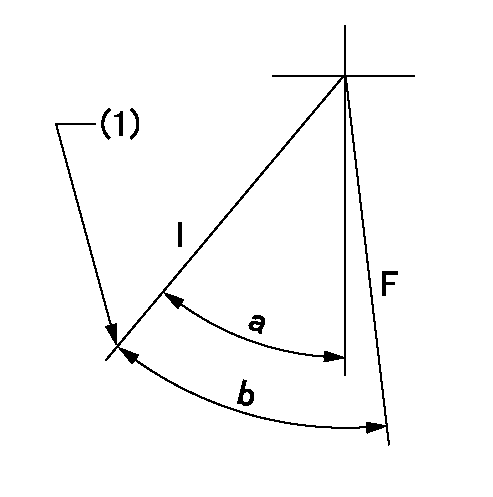

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=37deg+-5deg b=40deg+-3deg

----------

----------

a=37deg+-5deg b=40deg+-3deg

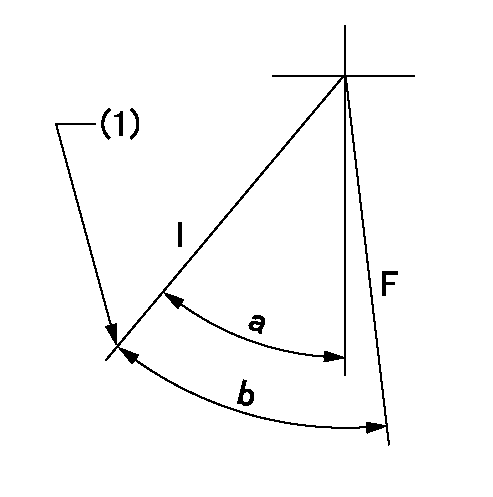

Stop lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=37deg+-5deg b=40deg+-3deg

----------

----------

a=37deg+-5deg b=40deg+-3deg

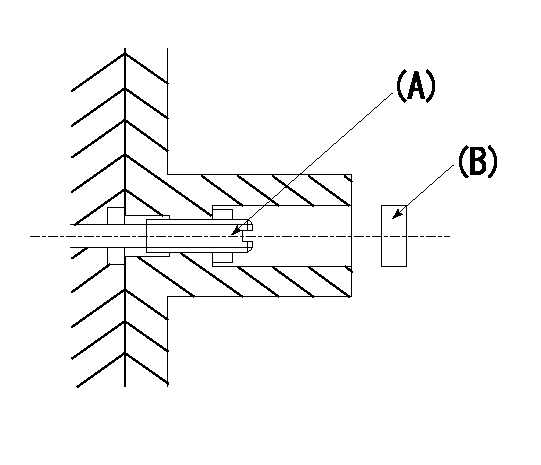

0000001501 TAMPER PROOF

Tamper proof adjustment

(1)Set the full load screw at rack position Ra+0.4.

(2)Set the full load position Ra using screw (A).

----------

Ra=R1(10.3)mm

----------

----------

Ra=R1(10.3)mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=14deg

----------

a=(60deg)

----------

aa=14deg

----------

a=(60deg)

Information:

Before completing the attached Rework Procedure, review the safety actions in the Operation and Maintenance Manual for safety information and safe working practices before starting the rework.

If the head gasket has failed replace the head gasket and the fuel

injection pump.

If the head gasket has not failed replace the fuel injection pump only.

The 483-2326 Fuel Injection Pump has revised injection timing to reduce the peak cylinder pressure in the engine. It is essential that the pump is installed as per the Disassembly and Assembly, "Fuel Injection Pump - Install - Delphi DP210" to achieve the desired fuel injection timing.

SERVICE CLAIM ALLOWANCES

****Parts Stock****

Submit one claim for all parts removed from dealer parts stock.

****Affected Product****

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

0-3000 hrs,

0-48 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 5.5-hour job

For After failure, and additional 13.8 hours is allowed. A maximum of $100 will be allowed for machining of cylinder head face to achieve required surface finish after failure.

PARTS DISPOSITION

****Parts Stock****

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

****Affected Product****

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Rework Procedure

If the head gasket has failed follow the rework procedure for both head gasket replacement and for fuel injection pump replacement

If the head gasket has not failed follow the rework procedure for fuel injection pump replacement only.

Head gasket replacement:

Confirm the head gasket has failed through removal of the cylinder head and visual inspection of the gasket. Remove cylinder head ? refer to Disassembly and Assembly, "Cylinder Head - Remove". Confirm head gasket has failed through visual inspection, as per the images shown in Image 1.1.1.

Clean the cylinder head face and the cylinder block face to remove any deposits on the gasket sealing surface using an appropriate cleaner. Do not use abrasive materials to remove the deposits during the cleaning process to ensure that the correct surface flatness is maintained.

Inspect cylinder head for flatness and distortion. Refer to Image 1.1.2 for surface finish. Refer to System Operation Testing and Adjusting, "Cylinder Head ? Inspect" for more information. Resurface the cylinder head if required as per Testing and Adjusting, "Cylinder Head ? Inspect".

Inspect cylinder block for surface finish on the top deck of the cylinder block. Refer to Image 1.1.2 for surface finish. If the cylinder block is within specifications, install a new 258-4946 Cylinder Head Gasket. If the block is not within specification, refer to Reuse And Salvage Guidelines, SEBF8076, "Specifications to Salvage Contact Surfaces of Cylinder Blocks" for more information.

Note: A 369-3705 Cylinder Head Gasket may be required, depending on reuse and salvage guidelines.

Follow Disassembly and Assembly, "Cylinder Head ? Install" with a new gasket as per above information.

Fuel injection pump replacement:

Follow Disassembly and Assembly, "Fuel Injection Pump - Remove - Delphi DP210". Do not reuse the fuel pump. Record removed fuel pump serial number in claim story. The fuel pump serial number is in the format "12345ABC".

Install the new 483-2326