Information injection-pump assembly

ZEXEL

101603-0500

1016030500

ISUZU

1156018010

1156018010

Rating:

Cross reference number

ZEXEL

101603-0500

1016030500

ISUZU

1156018010

1156018010

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.7

3.65

3.75

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.4

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

92.8

91.2

94.4

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

11.7

9.7

13.7

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.4)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

92.8

91.8

93.8

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.2

Pump speed

r/min

550

550

550

Average injection quantity

mm3/st.

83.2

80

86.4

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

I

Rack position

R2(13.8)

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

103

103

113

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1150--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1100

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1250

Advance angle

deg.

3.1

2.6

3.6

Timer adjustment_04

Pump speed

r/min

1350

Advance angle

deg.

6

5.5

6.5

Remarks

Finish

Finish

Test data Ex:

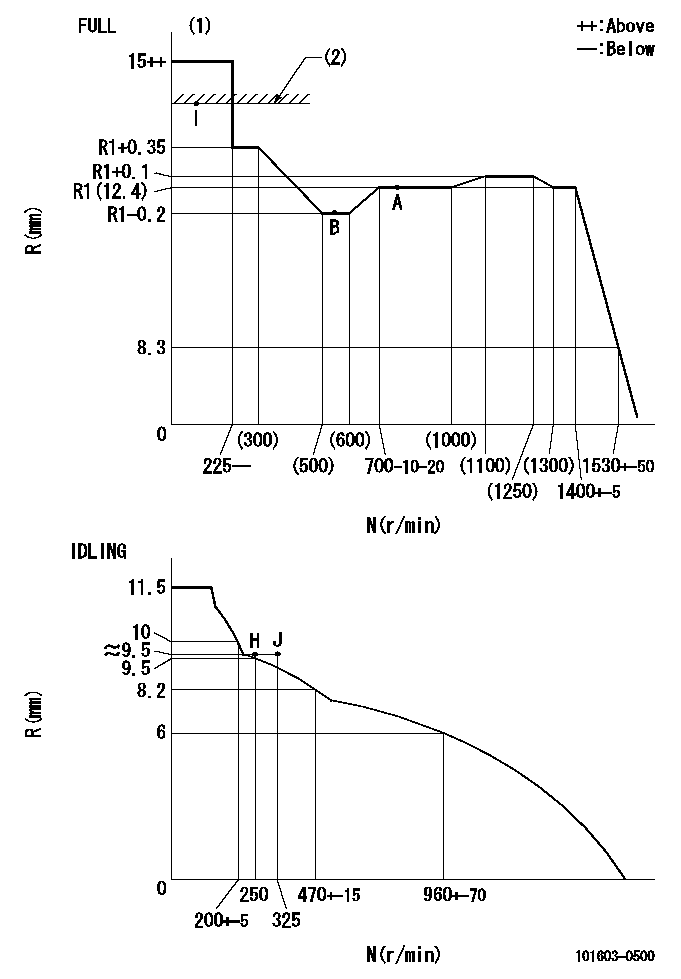

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

----------

T1=B01

----------

----------

T1=B01

----------

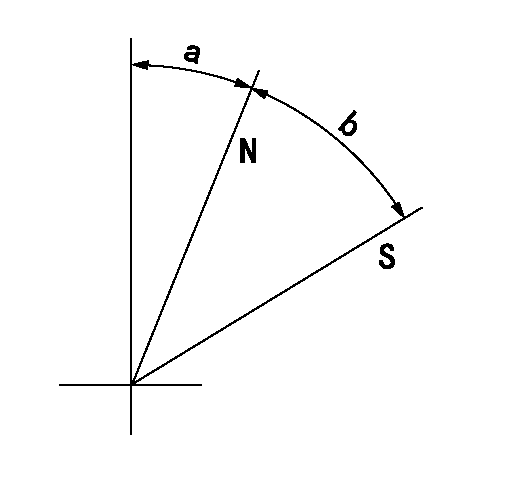

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=18deg+-5deg b=33deg+-3deg

----------

----------

a=18deg+-5deg b=33deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=25deg+-5deg b=40deg+-5deg

----------

----------

a=25deg+-5deg b=40deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(30deg)

----------

----------

a=(30deg)

Information:

Fuel Filter Group

(1) Remove clips (1) and (2). Remove tube assembly (3) and elbow (4) from the fuel transfer pump on the replacement engine. Installation of new line is shown in Fuel Lines Group, Page 8.Fuel Tank Group

(1) Remove the fuel tank from the machine; see the Service Manual. (2) Fabricate boss (1) to the dimensions shown. Make 1/8" - 27 NPTF threads in one end. (3) Drill a 20.0 mm Ø (0.78" Ø) hole (A) through the bottom of the tank as shown. (4) Put boss (1) in hole (A) with the threaded end extending below the bottom of the full tank as shown. Make a 3.0 mm (0.12") fillet weld all around the boss.(5) Clean and install the fuel tank; see the Service Manual.Fuel Lines Group

(1) Remove fuel inlet hose (1) and tube assembly (2) from tube (A). (2) Install 307946 Elbow (3) and a 3J7354 Seal in the fuel transfer pump. Install 2V4869 Fitting (4) on elbow (3). Cut a 360.0 mm (14.17") length of 5P1465 Hose (5), and connect it to fitting (4) and tube assembly (A) with the former clamps.(3) Install 6D238 Valve Assembly (7) in the boss installed in the fuel tank (see Step 4, Page 7). Fasten 5G5681 Tube (8) to valve assembly (7). Use L2072 Clamp (9) to hold the other end of tube (8) in position. Install clamp (9) under bolt (10).(4) Install 307941 Elbow (11) and a 3J7354 Seal in the fuel return port of the fuel injection pump housing. Install 2V4869 Fitting (12) on elbow (11).(5) Cut a 520.0 mm (20.47") length of 5P1465 Hose (13), and connect it to fitting (12) and tube (8) with a 1P4278 Clamp (14). An optional step to the above procedure is to connect a 60.0 mm (2.36") length of 5P189 Tube to valve assembly (7). Cut a 2000.0 mm (78.75") length of 5P6442 Hose and connect it to 2V4869 Fitting (12) and to the 5P189 Tube with a 1P4278 Clamp. Tie the hose to the machine to prevent damage to the hose.Electrical System

(1) For all machines, connect the alternator wire of the harness to the alternator.(2) For machines 80U1-80U6734, remove the original voltage regulator. Put tape over the wire connection to the wiring harness so it will be out of the way. The alternator for this engine has a built in voltage regulator so the original voltage regulator is not needed for the electrical system.Flywheel Group (For Replacement of 7N9437, 1W163 or 2W7488 Engine Arrangements)

(1) Remove the flywheel from the new replacement engine.(2) Install a new 7W2290 Flywheel Assembly, and fasten it to the crankshaft with four T489 Bolts. See the Service Manual for the procedure and the bolt torque. If necessary, use of the former flywheel from the engine being replaced is acceptable.Installation Of Ether Starting Aid Group

The ether starting aid is no longer a required component of direct injection engine arrangements.(1) If the machine is equipped with an ether starting aid group, its reuse is optional. To reuse,

(1) Remove clips (1) and (2). Remove tube assembly (3) and elbow (4) from the fuel transfer pump on the replacement engine. Installation of new line is shown in Fuel Lines Group, Page 8.Fuel Tank Group

(1) Remove the fuel tank from the machine; see the Service Manual. (2) Fabricate boss (1) to the dimensions shown. Make 1/8" - 27 NPTF threads in one end. (3) Drill a 20.0 mm Ø (0.78" Ø) hole (A) through the bottom of the tank as shown. (4) Put boss (1) in hole (A) with the threaded end extending below the bottom of the full tank as shown. Make a 3.0 mm (0.12") fillet weld all around the boss.(5) Clean and install the fuel tank; see the Service Manual.Fuel Lines Group

(1) Remove fuel inlet hose (1) and tube assembly (2) from tube (A). (2) Install 307946 Elbow (3) and a 3J7354 Seal in the fuel transfer pump. Install 2V4869 Fitting (4) on elbow (3). Cut a 360.0 mm (14.17") length of 5P1465 Hose (5), and connect it to fitting (4) and tube assembly (A) with the former clamps.(3) Install 6D238 Valve Assembly (7) in the boss installed in the fuel tank (see Step 4, Page 7). Fasten 5G5681 Tube (8) to valve assembly (7). Use L2072 Clamp (9) to hold the other end of tube (8) in position. Install clamp (9) under bolt (10).(4) Install 307941 Elbow (11) and a 3J7354 Seal in the fuel return port of the fuel injection pump housing. Install 2V4869 Fitting (12) on elbow (11).(5) Cut a 520.0 mm (20.47") length of 5P1465 Hose (13), and connect it to fitting (12) and tube (8) with a 1P4278 Clamp (14). An optional step to the above procedure is to connect a 60.0 mm (2.36") length of 5P189 Tube to valve assembly (7). Cut a 2000.0 mm (78.75") length of 5P6442 Hose and connect it to 2V4869 Fitting (12) and to the 5P189 Tube with a 1P4278 Clamp. Tie the hose to the machine to prevent damage to the hose.Electrical System

(1) For all machines, connect the alternator wire of the harness to the alternator.(2) For machines 80U1-80U6734, remove the original voltage regulator. Put tape over the wire connection to the wiring harness so it will be out of the way. The alternator for this engine has a built in voltage regulator so the original voltage regulator is not needed for the electrical system.Flywheel Group (For Replacement of 7N9437, 1W163 or 2W7488 Engine Arrangements)

(1) Remove the flywheel from the new replacement engine.(2) Install a new 7W2290 Flywheel Assembly, and fasten it to the crankshaft with four T489 Bolts. See the Service Manual for the procedure and the bolt torque. If necessary, use of the former flywheel from the engine being replaced is acceptable.Installation Of Ether Starting Aid Group

The ether starting aid is no longer a required component of direct injection engine arrangements.(1) If the machine is equipped with an ether starting aid group, its reuse is optional. To reuse,