Information injection-pump assembly

BOSCH

9 400 614 983

9400614983

ZEXEL

101602-9771

1016029771

NISSAN-DIESEL

1679095011

1679095011

Rating:

Include in #2:

104742-1260

as _

Cross reference number

BOSCH

9 400 614 983

9400614983

ZEXEL

101602-9771

1016029771

NISSAN-DIESEL

1679095011

1679095011

Zexel num

Bosch num

Firm num

Name

101602-9771

9 400 614 983

1679095011 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

NE6T * K 14BE INJECTION PUMP ASSY PE6A PE

NE6T * K 14BE INJECTION PUMP ASSY PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

2.75

2.7

2.8

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.8

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

86.8

85.3

88.3

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.1+-0.5

Pump speed

r/min

430

430

430

Average injection quantity

mm3/st.

14.5

13

16

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

68

68

88

Fixing the lever

*

Rack limit

*

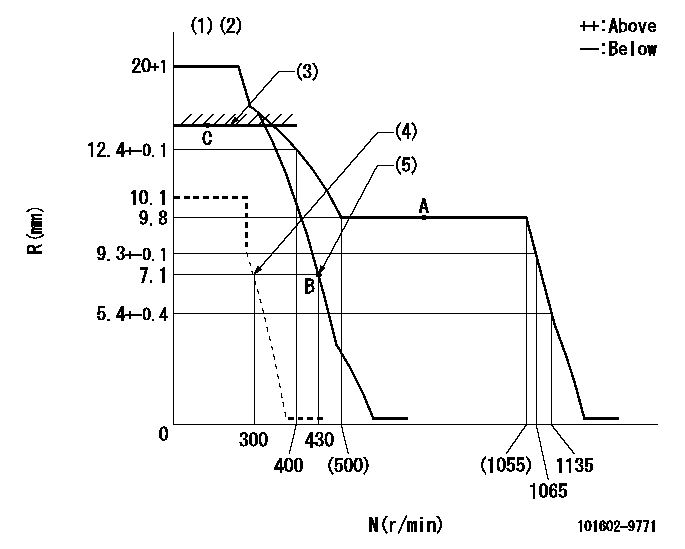

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

----------

K=14

----------

----------

K=14

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=9deg+-5deg b=18deg+-5deg

----------

----------

a=9deg+-5deg b=18deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=18deg

----------

a=(30deg)

----------

aa=18deg

----------

a=(30deg)

Information:

Start By:a. remove governor 1. Remove the bolts and the plate from the side of the fuel injection pump housing.2. Install Tool (A) in the fuel injection pump housing. Move the rack until Tool (A) can be installed to hold the rack in the center position. The rack must be in the center position to remove the fuel injection pumps.3. Use Tool (B) to remove bushing (1) from the fuel injection pump housing.4. Remove the O-ring seal from the fuel injection pump housing. Spacers (2) are the same thickness for each fuel injection pump so they can be mixed. The fuel injection pump plungers and barrels are sets and can not be mixed.5. Install Tool (C) on the bonnet. Remove the fuel injection pump. 6. Remove spacer (2) from the fuel injection pump housing.7. Do Steps 3 through 6 to remove the other fuel injection pumps.Install Fuel Injection Pumps

1. Install spacer (1) in the fuel injection pump housing. 2. Install Tool (A) in the fuel injection pump housing. Move the rack until Tool (A) can be installed to hold the rack in the center position. The rack must be in the center position to install the fuel injection pumps.3. Turn the camshaft until the lobe of the camshaft is down for the pump to be installed.4. Install Tool (B) on the bonnet of the fuel injection pump.5. Install the fuel injection pump in the pump housing with saw cut (slot) (3) in the gear in alignment with the small pin (2) and groove (4) in the barrel in alignment with dowel (5) in the pump housing. 6. Put clean oil on O-ring seal (6). Install it in the fuel injection pump housing.7. Install the bushing by hand until it is even with the top of the housing. If the bushing can not be installed this far by hand, remove it. Remove the fuel injection pump, and put the pump in alignment again, and install the bushing again. 8. Install Tool (C) on the bushing and tighten the bushing to a torque of 190 14 N m (140 10 lb ft). 9. Install Tool (D) to measure total rack travel. Correct rack travel is 15.7 mm (.618 in). A smaller measurement is an indication of incorrect fuel injection pump installation.10. Do Steps 1 through 9 again for installation of the other fuel pumps.11. Install the cover and gasket on the fuel injection pump housing.End By:a. install governorDisassemble Fuel Injection Pumps

Start By:a. remove fuel injection pumps

Be careful when the injection pumps are disassembled. Do not damage the surfaces of the plungers, barrels and bonnets. Any scratches will cause leakage inside the fuel injection pump. The plunger and barrel for each pump are made as a set. Do not put the plunger of one pump in the barrel of another pump. If one part has wear, install a complete new pump assembly. Be careful when the plunger is put into the bore of the barrel.

1. Pull plunger (1) and

1. Install spacer (1) in the fuel injection pump housing. 2. Install Tool (A) in the fuel injection pump housing. Move the rack until Tool (A) can be installed to hold the rack in the center position. The rack must be in the center position to install the fuel injection pumps.3. Turn the camshaft until the lobe of the camshaft is down for the pump to be installed.4. Install Tool (B) on the bonnet of the fuel injection pump.5. Install the fuel injection pump in the pump housing with saw cut (slot) (3) in the gear in alignment with the small pin (2) and groove (4) in the barrel in alignment with dowel (5) in the pump housing. 6. Put clean oil on O-ring seal (6). Install it in the fuel injection pump housing.7. Install the bushing by hand until it is even with the top of the housing. If the bushing can not be installed this far by hand, remove it. Remove the fuel injection pump, and put the pump in alignment again, and install the bushing again. 8. Install Tool (C) on the bushing and tighten the bushing to a torque of 190 14 N m (140 10 lb ft). 9. Install Tool (D) to measure total rack travel. Correct rack travel is 15.7 mm (.618 in). A smaller measurement is an indication of incorrect fuel injection pump installation.10. Do Steps 1 through 9 again for installation of the other fuel pumps.11. Install the cover and gasket on the fuel injection pump housing.End By:a. install governorDisassemble Fuel Injection Pumps

Start By:a. remove fuel injection pumps

Be careful when the injection pumps are disassembled. Do not damage the surfaces of the plungers, barrels and bonnets. Any scratches will cause leakage inside the fuel injection pump. The plunger and barrel for each pump are made as a set. Do not put the plunger of one pump in the barrel of another pump. If one part has wear, install a complete new pump assembly. Be careful when the plunger is put into the bore of the barrel.

1. Pull plunger (1) and

Have questions with 101602-9771?

Group cross 101602-9771 ZEXEL

Yanmar

Nissan-Diesel

Nissan-Diesel

Mitsubishi-Heav

Nissan-Diesel

101602-9771

9 400 614 983

1679095011

INJECTION-PUMP ASSEMBLY

NE6T

NE6T