Information injection-pump assembly

ZEXEL

101602-9641

1016029641

NISSAN-DIESEL

16790Z5569

16790z5569

Rating:

Service parts 101602-9641 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600Z5511

12.

Open Pre:MPa(Kqf/cm2)

19.6(200)

15.

NOZZLE SET

Include in #1:

101602-9641

as INJECTION-PUMP ASSEMBLY

Include in #2:

104741-6631

as _

Cross reference number

ZEXEL

101602-9641

1016029641

NISSAN-DIESEL

16790Z5569

16790z5569

Zexel num

Bosch num

Firm num

Name

101602-9641

16790Z5569 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

FD6 * K

FD6 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3

2.95

3.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

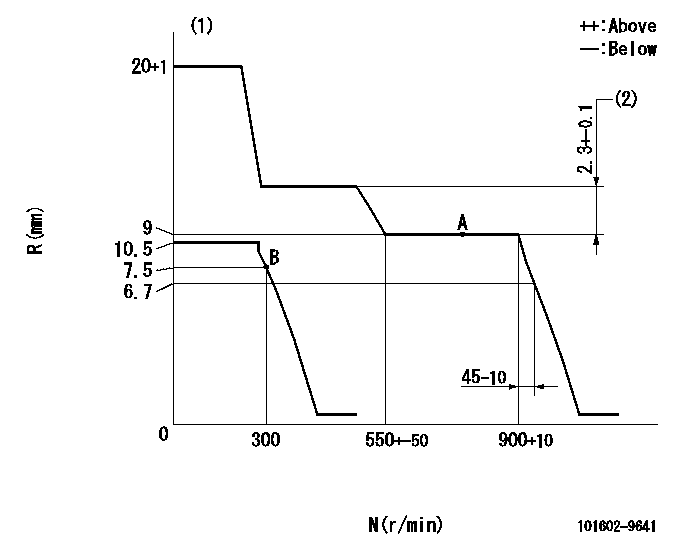

Injection quantity adjustment

Adjusting point

A

Rack position

9

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

44.7

43.1

46.3

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.5+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

8.2

6.4

10

Max. variation between cylinders

%

0

-12

12

Fixing the rack

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Rack difference between N = N1 and N = N2

----------

K=10 N1=750r/min N2=400r/min

----------

----------

K=10 N1=750r/min N2=400r/min

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(3deg)+-5deg b=(21deg)+-5deg

----------

----------

a=(3deg)+-5deg b=(21deg)+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of coupling's threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Termination Date

January 31, 1993Problem

The fuel injection pumps used on certain Remanufactured 1160 and 3208 Engines need to be inspected for gummy deposits.

Affected Product

Model & Identification Number

1160 (57V1-34325)

3208 (9WC1-730; 5CD1-5868; 62W1-68596; 93Z1-8374)

Remanufactured Fuel Pump Part Numbers

0R07660R09030R23840R23860R09020R23740R23850R2877 The above list of remanufactured pumps are affected only if they are stamped with a date code of 12/91 (UMDU) or earlier.

Parts Needed

Not Applicable

Action Required

Before installing or delivering any of the affected product, perform the following steps to ensure the internal fuel injection pump components are not stuck due to fuel pump gumming:

1. Remove the top cover of the fuel injection pump and check to ensure that all sleeves and levers are free and there are no gummy deposits on any of these components.2. If inspection performed in Step 1 indicates everything is clean, install top cover and return to parts stock.3. If inspection reveals components have gummy deposits, remove 12 ounces of fuel from the fuel pump housing and replace it with: - Fuel Injector Cleaner or

- Carburetor/Choke Cleaner

4. Allow the components to soak in cleaning solution for 45 minutes, then rotate the engine crankshaft to rotate the fuel injection pump (on pumps only, rotate the fuel pump camshaft). This will ensure the components have the gummy deposits removed. If the engine or fuel pump will be used immediately, install the cover on the fuel injection pump, and install or deliver the engine or pump.5. If the engine or fuel pump will be returned to stock, DO NOT leave the fuel injection pump full of cleaning solution because it may not contain any rust inhibitors. Remove the cleaning solution, fill the fuel injector pump with clean diesel fuel, and install the cover on the pump.Service Claim Allowances

It is a .5-hr. job to inspect the pump. An additional .5-hr. may be claimed if cleaning is required.

Parts Disposition

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

January 31, 1993Problem

The fuel injection pumps used on certain Remanufactured 1160 and 3208 Engines need to be inspected for gummy deposits.

Affected Product

Model & Identification Number

1160 (57V1-34325)

3208 (9WC1-730; 5CD1-5868; 62W1-68596; 93Z1-8374)

Remanufactured Fuel Pump Part Numbers

0R07660R09030R23840R23860R09020R23740R23850R2877 The above list of remanufactured pumps are affected only if they are stamped with a date code of 12/91 (UMDU) or earlier.

Parts Needed

Not Applicable

Action Required

Before installing or delivering any of the affected product, perform the following steps to ensure the internal fuel injection pump components are not stuck due to fuel pump gumming:

1. Remove the top cover of the fuel injection pump and check to ensure that all sleeves and levers are free and there are no gummy deposits on any of these components.2. If inspection performed in Step 1 indicates everything is clean, install top cover and return to parts stock.3. If inspection reveals components have gummy deposits, remove 12 ounces of fuel from the fuel pump housing and replace it with: - Fuel Injector Cleaner or

- Carburetor/Choke Cleaner

4. Allow the components to soak in cleaning solution for 45 minutes, then rotate the engine crankshaft to rotate the fuel injection pump (on pumps only, rotate the fuel pump camshaft). This will ensure the components have the gummy deposits removed. If the engine or fuel pump will be used immediately, install the cover on the fuel injection pump, and install or deliver the engine or pump.5. If the engine or fuel pump will be returned to stock, DO NOT leave the fuel injection pump full of cleaning solution because it may not contain any rust inhibitors. Remove the cleaning solution, fill the fuel injector pump with clean diesel fuel, and install the cover on the pump.Service Claim Allowances

It is a .5-hr. job to inspect the pump. An additional .5-hr. may be claimed if cleaning is required.

Parts Disposition

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Have questions with 101602-9641?

Group cross 101602-9641 ZEXEL

Nissan-Diesel

Daewoo

Nissan-Diesel

101602-9641

16790Z5569

INJECTION-PUMP ASSEMBLY

FD6

FD6