Information injection-pump assembly

BOSCH

9 400 614 978

9400614978

ZEXEL

101602-9571

1016029571

NISSAN-DIESEL

16712Z5505

16712z5505

Rating:

Service parts 101602-9571 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600Z5515

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Include in #1:

101602-9571

as INJECTION-PUMP ASSEMBLY

Include in #2:

104741-6593

as _

Cross reference number

BOSCH

9 400 614 978

9400614978

ZEXEL

101602-9571

1016029571

NISSAN-DIESEL

16712Z5505

16712z5505

Zexel num

Bosch num

Firm num

Name

101602-9571

9 400 614 978

16712Z5505 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

FD6T K 14BE INJECTION PUMP ASSY PE6A PE

FD6T K 14BE INJECTION PUMP ASSY PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3

2.95

3.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.8

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

63.9

62.3

65.5

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

9.3

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

54.1

52.5

55.7

Max. variation between cylinders

%

0

-3

3

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

7.2+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

8.1

6.3

9.9

Max. variation between cylinders

%

0

-12

12

Fixing the rack

*

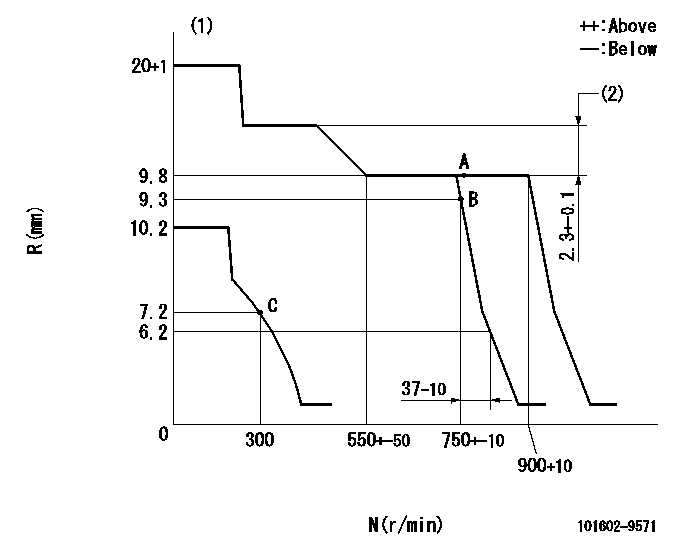

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Rack difference between N = N1 and N = N2

----------

K=13 N1=900r/min N2=400r/min

----------

----------

K=13 N1=900r/min N2=400r/min

----------

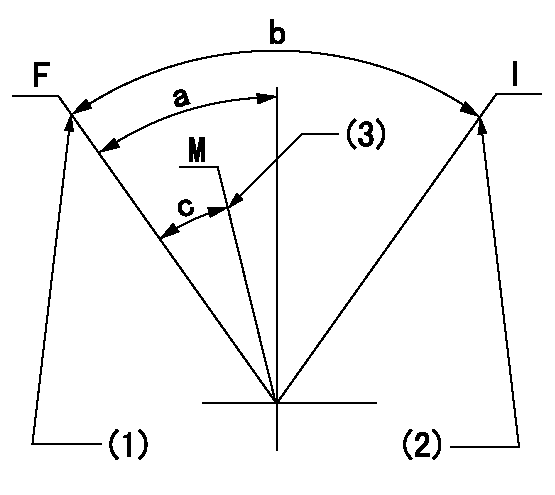

Speed control lever angle

F:Full speed

I:Idle

M:Minimum-maximum speed

(1)Set the pump speed at aa. ( At delivery )

(2)Stopper bolt setting

(3)Set the pump speed at bb.

----------

aa=900r/min bb=750r/min

----------

a=6deg+-5deg b=24deg+-5deg c=6deg+-5deg

----------

aa=900r/min bb=750r/min

----------

a=6deg+-5deg b=24deg+-5deg c=6deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

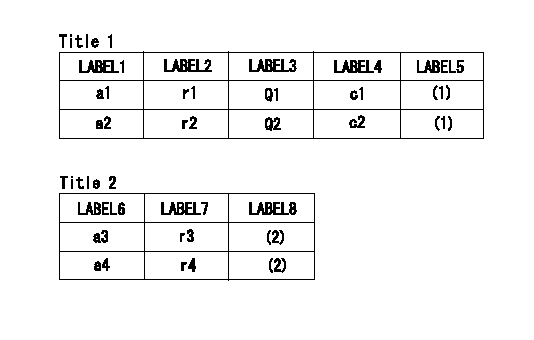

0000001501 GOV FULL LOAD ADJUSTMENT

Title1:Full load stopper adjustment

Title2:Governor set speed

LABEL1:Distinguishing

LABEL2:Pump speed (r/min)

LABEL3:Ave. injection quantity (mm3/st)

LABEL4:Max. var. bet. cyl.

LABEL5:Remarks

LABEL6:Distinguishing

LABEL7:Governor set speed (r/min)

LABEL8:Remarks

(1)Adjustment conditions are the same as those for measuring injection quantity.

(2)-

----------

----------

a1=A a2=B r1=750r/min r2=750r/min Q1=68.7+-1.6mm3/st Q2=63.9+-1.6mm3/st c1=+-2% c2=+-2% a3=18 a4=15 r3=900r/min r4=750r/min

----------

----------

a1=A a2=B r1=750r/min r2=750r/min Q1=68.7+-1.6mm3/st Q2=63.9+-1.6mm3/st c1=+-2% c2=+-2% a3=18 a4=15 r3=900r/min r4=750r/min

Timing setting

(1)Pump vertical direction

(2)Position of coupling's threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Caterpillar: Confidential Yellow

PSP FOR INSTALLING AN AUTOMATIC ETHER INJECTION SYSTEM (AEIS) ON CERTAIN D11N TRACTORS - PS4429 - MAILED US AND CANADA, COFA, CO SA, LIMITED CACO, LIMITED CFEL

The information supplied in this service letter may not be valid after the termination date of this program. Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

U-33 A-25.1 AU-22 E-28.1 O-31 Revised 03/02/91 to correct part number error. In list of parts, 9X1047 Collar should read 9X0147 Collar. 1456 PS4429 This Program can be administered either before or after a failure. In either case the decision whether to apply the Program is made by the dealer. When reporting the repair, use "PS4429" as Part Number, "7755" as Group Number, and "96" as Description Code. Termination Date

February 29, 1992

Problem

Certain D11N Tractors equipped with a manual ether starting aid may experience problems during cold starts. An Automatic Ether Injection System (AEIS) can be installed to improve starting and combustion during cold startups and increase the service life of the engine.

Affected Product

Model Identification Number D11N 74Z1-729

Parts Needed

2 - 3B6768 Bushing 2 - 4B4274 Washer 2 - 8B0114 Spacer 8 - 8C5607 Mount 4 - 8C5608 Spacer 1 - 8C9006 Tee 1 - 8C9812 Switch Assembly 2 - 9D2867 Lens 2 - 9D3127 Base Assembly 2 - 8E0993 Plate 2 - 8E1355 Plate 1 - 8E1415 Valve Assembly 1 - 8E1446 Inlay 1 - 8E6595 Harness Assembly 1 - 9G9813 Alarm Group 1 - 4H1641 Pin 1 - 3J1907 Seal 1 - 3J5390 Plug 1 - 7J6596 Fitting Assembly 10 - 7K1181 Strap 1 - 2L8077 Terminal 1 - 2L8079 Terminal 8 - 4M0061 Bolt 8 - 5M3062 Bolt 1 - 8M2772 Clip 2 - 2N7456 Screw 2 - 7N5876

PSP FOR INSTALLING AN AUTOMATIC ETHER INJECTION SYSTEM (AEIS) ON CERTAIN D11N TRACTORS - PS4429 - MAILED US AND CANADA, COFA, CO SA, LIMITED CACO, LIMITED CFEL

The information supplied in this service letter may not be valid after the termination date of this program. Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

U-33 A-25.1 AU-22 E-28.1 O-31 Revised 03/02/91 to correct part number error. In list of parts, 9X1047 Collar should read 9X0147 Collar. 1456 PS4429 This Program can be administered either before or after a failure. In either case the decision whether to apply the Program is made by the dealer. When reporting the repair, use "PS4429" as Part Number, "7755" as Group Number, and "96" as Description Code. Termination Date

February 29, 1992

Problem

Certain D11N Tractors equipped with a manual ether starting aid may experience problems during cold starts. An Automatic Ether Injection System (AEIS) can be installed to improve starting and combustion during cold startups and increase the service life of the engine.

Affected Product

Model Identification Number D11N 74Z1-729

Parts Needed

2 - 3B6768 Bushing 2 - 4B4274 Washer 2 - 8B0114 Spacer 8 - 8C5607 Mount 4 - 8C5608 Spacer 1 - 8C9006 Tee 1 - 8C9812 Switch Assembly 2 - 9D2867 Lens 2 - 9D3127 Base Assembly 2 - 8E0993 Plate 2 - 8E1355 Plate 1 - 8E1415 Valve Assembly 1 - 8E1446 Inlay 1 - 8E6595 Harness Assembly 1 - 9G9813 Alarm Group 1 - 4H1641 Pin 1 - 3J1907 Seal 1 - 3J5390 Plug 1 - 7J6596 Fitting Assembly 10 - 7K1181 Strap 1 - 2L8077 Terminal 1 - 2L8079 Terminal 8 - 4M0061 Bolt 8 - 5M3062 Bolt 1 - 8M2772 Clip 2 - 2N7456 Screw 2 - 7N5876

Have questions with 101602-9571?

Group cross 101602-9571 ZEXEL

Nissan-Diesel

101602-9571

9 400 614 978

16712Z5505

INJECTION-PUMP ASSEMBLY

FD6T

FD6T