Information injection-pump assembly

ZEXEL

101602-9410

1016029410

Rating:

Cross reference number

ZEXEL

101602-9410

1016029410

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3

2.95

3.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.5

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

73.2

72.2

74.2

Max. variation between cylinders

%

0

-5

5

Fixing the lever

*

Boost pressure

kPa

14.7

14.7

Boost pressure

mmHg

110

110

Injection quantity adjustment_02

Adjusting point

B

Rack position

9.3

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

55

54

56

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

14.7

14.7

Boost pressure

mmHg

110

110

Injection quantity adjustment_03

Adjusting point

C

Rack position

8.7

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

42.6

40.6

44.6

Max. variation between cylinders

%

0

-5

5

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_04

Adjusting point

D

Rack position

7.8+-0.5

Pump speed

r/min

290

290

290

Average injection quantity

mm3/st.

9.5

7.7

11.3

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_05

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

57

57

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

8.7

Boost pressure

kPa

4

4

4

Boost pressure

mmHg

30

30

30

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

9.3

Boost pressure

kPa

6.7

5.4

8

Boost pressure

mmHg

50

40

60

Test data Ex:

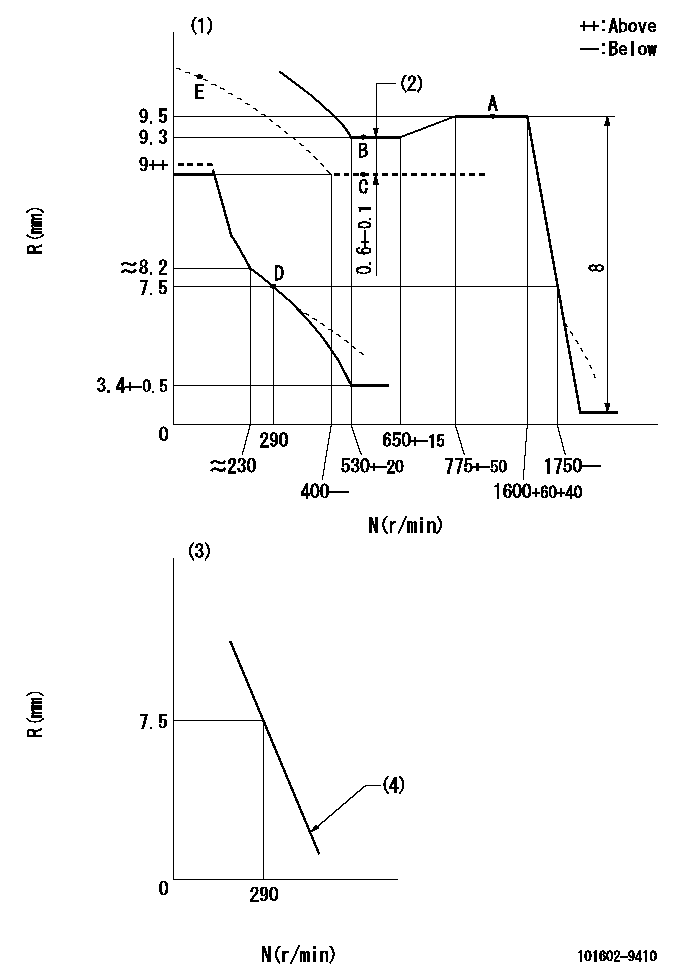

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Beginning of damper spring operation: DL

(2)Boost compensator stroke

(3)Variable speed specification: idling adjustment

(4)Main spring setting

----------

DL=6.5-0.2mm

----------

----------

DL=6.5-0.2mm

----------

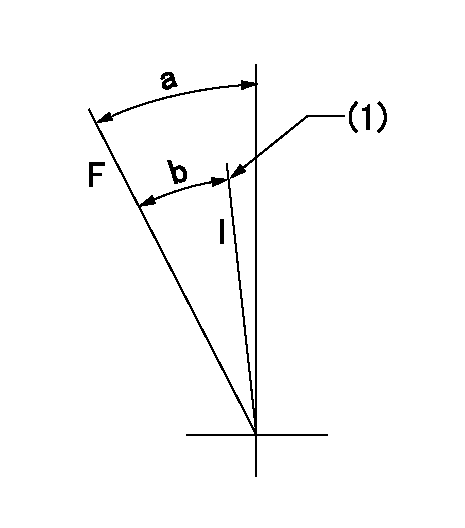

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=22deg+-5deg b=(18deg)

----------

----------

a=22deg+-5deg b=(18deg)

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=19deg+-5deg b=22deg+-3deg

----------

----------

a=19deg+-5deg b=22deg+-3deg

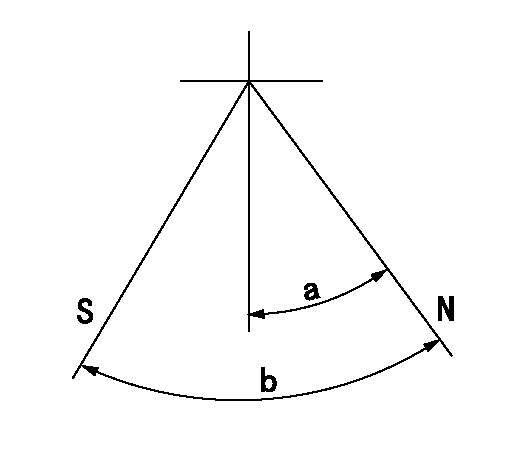

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=45deg+-5deg b=71deg+-5deg

----------

----------

a=45deg+-5deg b=71deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(30deg)

----------

----------

a=(30deg)

Information:

Typical 12 Volt Starting Circuit

(1) Test point. (2) Test point. (3) Test Point. (4) Test Point. (5) Test Point. (X) Hold-in coil. (W) Pull-in coil.General Information

All starting systems are made up of four elements. They are the ignition switch, start relay, the starting motor solenoid and starting motor. The only exception to this is that on some small engines the start relay may not be required. In this case, the start switch powers the starting motor solenoid directly.Start switches are relatively low current devices. They are rated to switch approximately 5 to 20 amps. Because the coil of a start relay [between test point (1) and (2)] draws about 1 amp, the start switch can easily turn on the start relay and have long life.The switch contacts of a typical start relay are rated to switch between 100 and 300 amps. Because the solenoid requires 5 to 50 amps, the start relay can easily switch this load.The starting motor solenoid has two functions: 1) it engages the pinion with the flywheel, and 2) it is a high current switch rated about 1000 amps that actually turns on the starting motor.The starting motor solenoid has two coils. Pull-in coil (W) draws about 40 amps and hold-in coil (X) requires about 5 amps. The instant the start relay closes, both coils (W) and (X) receive power. Battery voltage is applied to the high end of both coils, at test point (3) which is the start (S) terminal. The low end of hold-in coil (X) is permanently grounded to the ground post or motor housing of the starting motor. Grounding for the low end, test point (4), of pull-in coil (W) is momentary, and takes place through the DC resistance of the starting motor. As soon as magnetic force builds in both coils, the pinion moves toward the flywheel ring gear. The pinion will stop short of engagement of the flywheel ring gear. Only then will the solenoid contacts close to power the starting motor. This temporarily removes the ground from pull-in coil (W), and puts battery voltage on both ends of it while the starting motor cranks. During this period, the pull-in coil is out of the circuit. Cranking continues until power to the solenoid is broken by releasing the ignition switch.The result of these switches and relays is to permit a 5 amp dash-mounted switch to turn on a 500 to 1000 amp motor used to crank an engine.Battery voltage (power) available during cranking varies according to the temperature of the batteries. The following chart is a guide as to what to expect from a normal system. The next chart shows maximum acceptable voltage loss in the high current battery circuit feeding the starting motor. These values are maximums for machines of approximately 2000 SMH and up. Newer machines would be less than those shown. Voltages greater than those shown are most often caused by loose and/or corroded connections or defective switch contacts.Diagnosis Procedure

Do not operate the starting motor