Information injection-pump assembly

ZEXEL

101602-9390

1016029390

Rating:

Cross reference number

ZEXEL

101602-9390

1016029390

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3

2.95

3.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.5

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

73.2

72.2

74.2

Max. variation between cylinders

%

0

-5

5

Fixing the lever

*

Boost pressure

kPa

14.7

14.7

Boost pressure

mmHg

110

110

Injection quantity adjustment_02

Adjusting point

B

Rack position

9.3

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

55

54

56

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

14.7

14.7

Boost pressure

mmHg

110

110

Injection quantity adjustment_03

Adjusting point

C

Rack position

8.7

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

42.6

40.6

44.6

Max. variation between cylinders

%

0

-5

5

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_04

Adjusting point

D

Rack position

7.8+-0.5

Pump speed

r/min

290

290

290

Average injection quantity

mm3/st.

9.5

7.7

11.3

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_05

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

57

57

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

8.7

Boost pressure

kPa

4

4

4

Boost pressure

mmHg

30

30

30

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

9.3

Boost pressure

kPa

6.7

5.4

8

Boost pressure

mmHg

50

40

60

Test data Ex:

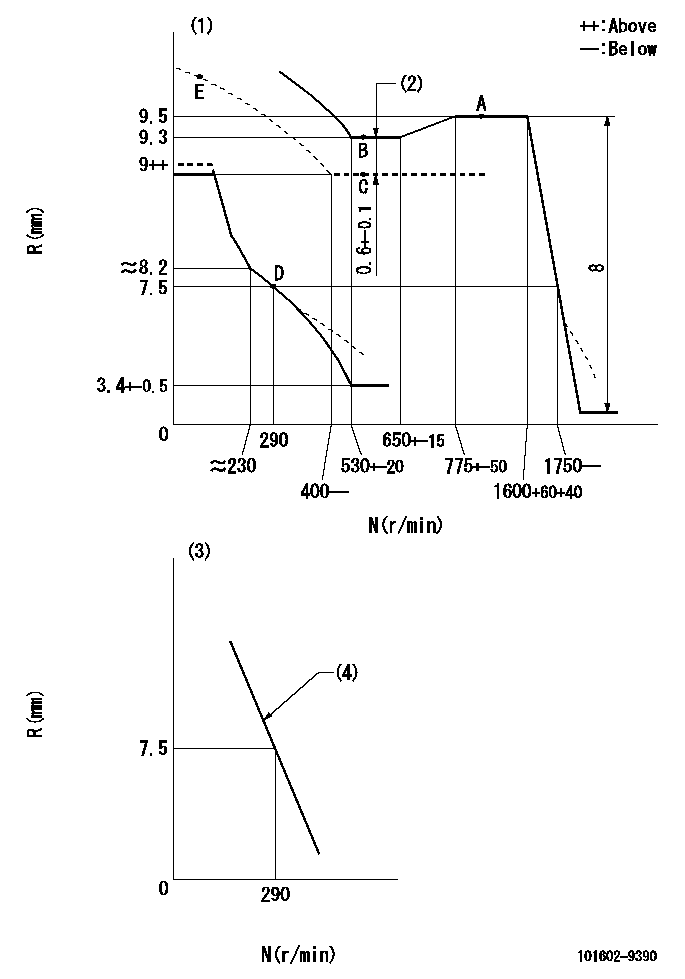

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Beginning of damper spring operation: DL

(2)Boost compensator stroke

(3)Variable speed specification: idling adjustment

(4)Main spring setting

----------

DL=6.5-0.2mm

----------

----------

DL=6.5-0.2mm

----------

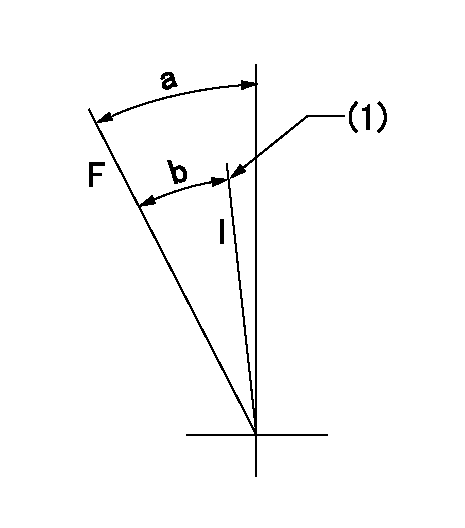

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=22deg+-5deg b=(18deg)

----------

----------

a=22deg+-5deg b=(18deg)

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=19deg+-5deg b=22deg+-3deg

----------

----------

a=19deg+-5deg b=22deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

----------

aa=20mm

----------

a=40deg+-5deg b=71deg+-5deg

----------

aa=20mm

----------

a=40deg+-5deg b=71deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(30deg)

----------

----------

a=(30deg)

Information:

4.236 Engines(1) First (top) compression ring: Width of compression ring ... 2.362 to 2.375 mm (.0930 to .0935 in)Clearance between ends of ring installed in cylinder liner that has no wear ... 0.25 to 0.56 mm (.010 to .022 in)(2) Second compression ring: Width of compression ring ... 2.362 to 2.375 mm (.0930 to .0935 in)Clearance between ends of each ring installed in cylinder liner that has no wear ... 0.20 to 0.56 mm (.008 to .022 in)(3) Oil ring: Width of oil ring ... 4.724 to 4.737 mm (.1860 to .1865 in)Clearance between ends of each ring installed in cylinder liner that has no wear ... 0.25 to 0.53 mm (.010 to .021 in)(4) Width of groove for first compression ring ... 2.46 to 2.49 mm (.097 to .098 in) Ring clearance in the groove ... 0.089 to 0.127 mm (.0035 to .0050 in)(5) Width of groove for second compression ring ... 2.44 to 2.46 mm (.096 to .097 in) Ring clearance in the groove ... 0.064 to 0.102 mm (.0025 to .0040 in)(6) Width of groove for oil ring ... 4.788 to 4.806 mm (.1885 to .1892 in) Ring clearance in the groove ... 0.051 to 0.081 mm (.0020 to .0032 in)(7) Bore in piston for pin ... 34.9212 to 34.9263 mm (1.37485 to 1.37505 in) Diameter of piston pin (new) ... 34.920 to 34.93 mm (1.3748 to 1.375 in)Piston height above cylinder block (not shown) ... 0.36 to 0.58 mm (.014 to .023 in)C4.236 Engines

C4.236 Engines(1) First (top) compression ring: Width of compression ring ... wedge shapedClearance between ends of ring installed in cylinder liner that has no wear ... 0.25 to 0.61 mm (.010 to .024 in)(2) Second compression ring: Width of compression ring ... 2.362 to 2.375 mm (.0930 to .0935 in)Clearance between ends of each ring installed in cylinder liner that has no wear ... 0.25 to 0.69 mm (.010 to .027 in)(3) Oil ring: Width of oil ring ... 4.724 to 4.763 mm (.1860 to .1875 in)Clearance between ends of each ring installed in cylinder liner that has no wear ... 0.25 to 0.79 mm (.010 to .031 in)(4) Width of groove for first compression ring ... tapered(5) Width of groove for second compression ring ... 2.426 to 2.446 mm (.0955 to .0963 in) Ring clearance in the groove ... 0.051 to 0.084 mm (.0020 to .0033 in)(6) Width of groove for oil ring ... 4.788 to 4.808 mm (.1885 to .1893 in) Ring clearance in the groove ... 0.025 to 0.084 mm (.0010 to .0033 in)(7) Bore in piston for pin ... 38.100 to 38.1005 mm (1.5000 to 1.50002 in) Diameter of piston pin (new) ... 38.095 to 38.100 mm (1.4998 to 1.5000 in)Piston height above cylinder block (not shown) ... 0.36 to 0.58 mm (.014 to .023 in)