Information injection-pump assembly

ZEXEL

101602-9380

1016029380

Rating:

Cross reference number

ZEXEL

101602-9380

1016029380

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3

2.95

3.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.5

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

73.2

72.2

74.2

Max. variation between cylinders

%

0

-5

5

Fixing the lever

*

Boost pressure

kPa

14.7

14.7

Boost pressure

mmHg

110

110

Injection quantity adjustment_02

Adjusting point

B

Rack position

9.3

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

55

54

56

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

14.7

14.7

Boost pressure

mmHg

110

110

Injection quantity adjustment_03

Adjusting point

C

Rack position

8.7

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

42.6

40.6

44.6

Max. variation between cylinders

%

0

-5

5

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_04

Adjusting point

D

Rack position

7.8+-0.5

Pump speed

r/min

290

290

290

Average injection quantity

mm3/st.

9.5

7.7

11.3

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_05

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

57

57

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

8.7

Boost pressure

kPa

4

4

4

Boost pressure

mmHg

30

30

30

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

9.3

Boost pressure

kPa

6.7

5.4

8

Boost pressure

mmHg

50

40

60

Test data Ex:

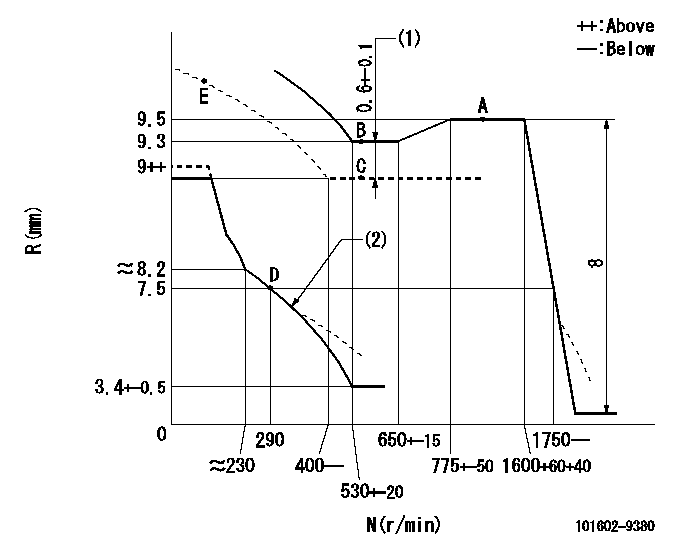

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Boost compensator stroke

(2)Beginning of damper spring operation: DL

----------

DL=6.5-0.2mm

----------

----------

DL=6.5-0.2mm

----------

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=19deg+-5deg b=22deg+-3deg

----------

----------

a=19deg+-5deg b=22deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

----------

aa=20mm

----------

a=40deg+-5deg b=71deg+-5deg

----------

aa=20mm

----------

a=40deg+-5deg b=71deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(30deg)

----------

----------

a=(30deg)

Information:

Earlier Engines

(1) Cylinder head bolts and nuts tightening procedure:1. Put engine oil on the threads of bolts and nuts. Tighten all bolts and nuts in number sequence to a torque of ... 45 N m (35 lb ft)2. Tighten all bolts and nuts in number sequence to a torque of ... 95 N m (70 lb ft)3. Again tighten all bolts and nuts in number sequence to a final torque of 135 N m (100 lb ft).Retighten the cylinder head bolts and nuts after the engine has run under part load for approximately thirty minutes.a. If the bolts and nuts move before the correct final torque is reached, retighten everything in the sequence again to the final torque of 135 N m (100 lb ft).b. If the bolts and nuts do not move before the correct final torque is reached, back each one off 30 to 60° (with an 8T3052 Degree Wheel) and retighten again, in the sequence shown, to the final torque. After all the bolts and nuts are retightened, check the first 10 positions to make sure they are tightened to the correct torque.c. After 25 to 50 hours of service for a new or rebuilt engine, retorque the cylinder head bolts as shown in Step a above and adjust the valves again. New cylinder blocks have been introduced on the 4.236 engine for the Backhoe Loaders. The new cylinder blocks have deeper cylinder head bolt holes and longer bolts. The old and new sizes are shown. The change became effective at engine serial number LD70178U027631M and UP. The engine serial number is located above the fuel injection pump on the block. The new cylinder head bolts are not interchangeable between old and new blocks. All other models will have the new arrangement at first production.Later Engines

New cylinder heads have been introduced on the 4.236 engine for the Backhoe Loaders. The new 4P4722 Cylinder Head is used with a 7C3191 Head Gasket and uses a new cylinder head torque procedure. The change became effective at engine serial number LD70178U419182U and UP. The change is adaptable to engines serial number LD70178U106654N and UP. The engine serial number is located above the fuel injection pump on the block.(1) Cylinder head bolts tightening procedure:a. Check the head bolts for any distortion with a straight edge along the threads. If there is a visual reduction in the thread diameter of any threads that have not been in engagement with the cylinder block, the bolt must be replaced.b. Put engine oil on the threads of bolts. Tighten all bolts in number sequence to a torque of ... 45 N m (35 lb ft).c. Tighten all bolts in number sequence to a torque of ... 95 N m (70 lb ft).d. Again tighten all bolts and nuts in number sequence to a torque of ... 120 N m (88 lb ft).e. Turn each bolt (with an 8T3052 Degree Wheel) in number sequence an additional

(1) Cylinder head bolts and nuts tightening procedure:1. Put engine oil on the threads of bolts and nuts. Tighten all bolts and nuts in number sequence to a torque of ... 45 N m (35 lb ft)2. Tighten all bolts and nuts in number sequence to a torque of ... 95 N m (70 lb ft)3. Again tighten all bolts and nuts in number sequence to a final torque of 135 N m (100 lb ft).Retighten the cylinder head bolts and nuts after the engine has run under part load for approximately thirty minutes.a. If the bolts and nuts move before the correct final torque is reached, retighten everything in the sequence again to the final torque of 135 N m (100 lb ft).b. If the bolts and nuts do not move before the correct final torque is reached, back each one off 30 to 60° (with an 8T3052 Degree Wheel) and retighten again, in the sequence shown, to the final torque. After all the bolts and nuts are retightened, check the first 10 positions to make sure they are tightened to the correct torque.c. After 25 to 50 hours of service for a new or rebuilt engine, retorque the cylinder head bolts as shown in Step a above and adjust the valves again. New cylinder blocks have been introduced on the 4.236 engine for the Backhoe Loaders. The new cylinder blocks have deeper cylinder head bolt holes and longer bolts. The old and new sizes are shown. The change became effective at engine serial number LD70178U027631M and UP. The engine serial number is located above the fuel injection pump on the block. The new cylinder head bolts are not interchangeable between old and new blocks. All other models will have the new arrangement at first production.Later Engines

New cylinder heads have been introduced on the 4.236 engine for the Backhoe Loaders. The new 4P4722 Cylinder Head is used with a 7C3191 Head Gasket and uses a new cylinder head torque procedure. The change became effective at engine serial number LD70178U419182U and UP. The change is adaptable to engines serial number LD70178U106654N and UP. The engine serial number is located above the fuel injection pump on the block.(1) Cylinder head bolts tightening procedure:a. Check the head bolts for any distortion with a straight edge along the threads. If there is a visual reduction in the thread diameter of any threads that have not been in engagement with the cylinder block, the bolt must be replaced.b. Put engine oil on the threads of bolts. Tighten all bolts in number sequence to a torque of ... 45 N m (35 lb ft).c. Tighten all bolts in number sequence to a torque of ... 95 N m (70 lb ft).d. Again tighten all bolts and nuts in number sequence to a torque of ... 120 N m (88 lb ft).e. Turn each bolt (with an 8T3052 Degree Wheel) in number sequence an additional