Information injection-pump assembly

BOSCH

9 400 611 253

9400611253

ZEXEL

101602-8950

1016028950

ISUZU

1156033280

1156033280

Rating:

Service parts 101602-8950 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

8-97222-170-0

12.

Open Pre:MPa(Kqf/cm2)

18.1{185}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 611 253

9400611253

ZEXEL

101602-8950

1016028950

ISUZU

1156033280

1156033280

Zexel num

Bosch num

Firm num

Name

9 400 611 253

1156033280 ISUZU

INJECTION-PUMP ASSEMBLY

6BG1-T * K 14BF PE6AD PE

6BG1-T * K 14BF PE6AD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4

3.95

4.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.3

Pump speed

r/min

1075

1075

1075

Average injection quantity

mm3/st.

89

87.5

90.5

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

7.5+-0.5

Pump speed

r/min

450

450

450

Average injection quantity

mm3/st.

9

7.7

10.3

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

150

145

155

Fixing the lever

*

Rack limit

*

Test data Ex:

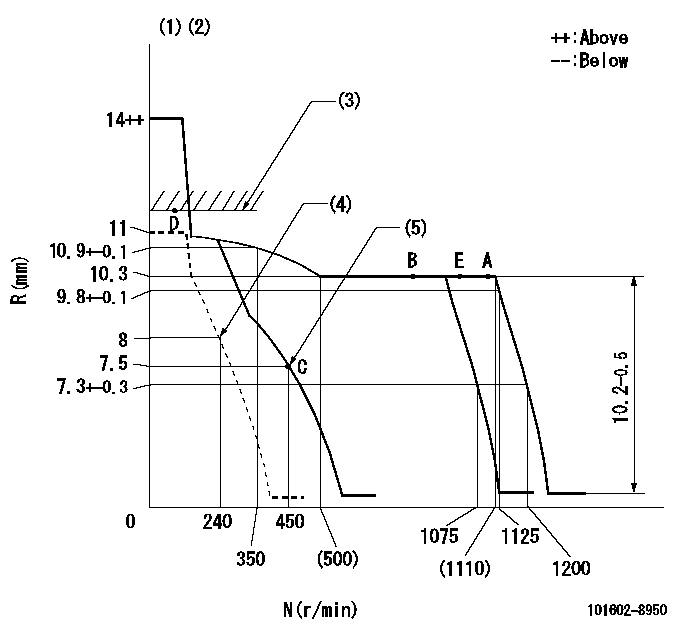

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

----------

K=9

----------

----------

K=9

----------

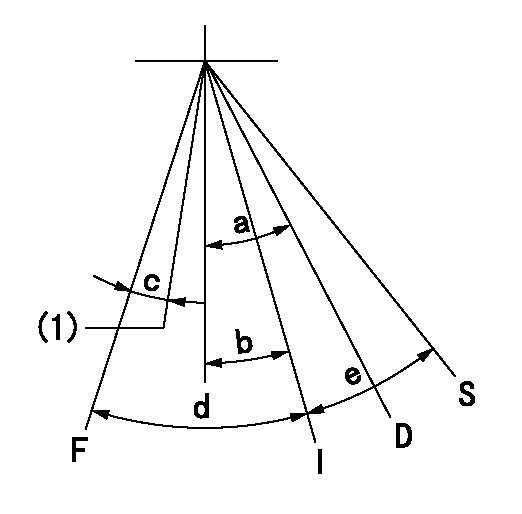

Speed control lever angle

F:Full speed

I:Idle

D:Dead point

S:Stop

(1)Pump speed = aa

----------

aa=1075r/min

----------

a=(20deg)+-3deg b=(14deg)+-5deg c=(3deg) d=(20deg)+-5deg e=(21deg)+-5deg

----------

aa=1075r/min

----------

a=(20deg)+-3deg b=(14deg)+-5deg c=(3deg) d=(20deg)+-5deg e=(21deg)+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=6deg+-5deg b=46deg+-5deg

----------

----------

a=6deg+-5deg b=46deg+-5deg

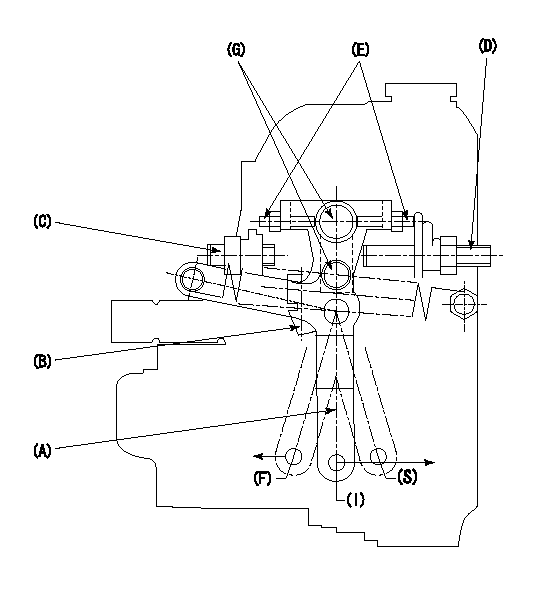

0000001501 LEVER

1. Variable lever adjustment

(1)Fix lever B in the idle position using the bolts C and D.

(2)Temporarily fix lever A in center of long hole.

(3)Set the dead point position temporarily and measure the lever angle.

(4)After idle adjustment, loosen the full side stopper bolt D.

(5)Move lever A in full speed direction.

(6)Fix the bolt D at the full speed position.

(7)Fix lever A using bolt E.

(8)(G) Lock using bolt.

(9)Finally, measure the lever angle and set the idle stopper bolt (C) stop position.

----------

----------

----------

----------

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'CC' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=10deg

----------

a=(100deg)

----------

aa=10deg

----------

a=(100deg)

Information:

Test Points (Voltages And Waveforms)

dc Voltages Conditions: 1. dc input voltage applied to POWER connector as shown.2. CALIBRATION CHECK/OPERATE switch in the OPERATE position.3. Neither transducer connected to indicator.4. TPI is reference for all voltages.Equipment Required: 6V3030 Digital Multimeterdc Input Voltages Waveforms Conditions: 1. dc power input voltage of 25 1 Volts.2. CALIBRATION CHECK/OPERATE switch in the CHECK position (can be held in CHECK position with tape).3. Neither transducer connected to indicator.4. TPI is reference for all waveforms.Equipment Required: dc oscilloscope (dual channel preferred). Waveform Time Relationships

VOLTAGES MAY VARY 10%, PULSE DURATIONS BY 20% EXCEPT 2.66 ms WHICH IS BASED ON A 12.000 kHz OSCILLATOR FREQ. (1C202). SIGNAL SOURCE IS INTERNAL CALIBRATOR. ALL TEST POINTS REFERENCED TO TP1.Waveform Time Relationships (enlarged scale)

VOLTAGES MAY VARY 10%, PULSE DURATIONS BY 20% EXCEPT 83.3 ?s AND 2.66 ms WHICH ARE EXACT BASED ON A 12.000 kHZ OSCILLATOR. (1C202) SIGNAL SOURCE IS INTERNAL CALIBRATOR. ALL TEST POINTS REFERENCED TO TP1.Disassembly Procedure

1 Remove six screws (1) from front panel (2), and remove panel (2) from case (3). Remove four screws (4) from the PC board, and also remove the locknuts from the two front panel switches (5) and (6). Carefully lift front panel (2) from PC (printed circuit) board (7).Calibration Procedure

To make sure the 6V3100 Timing Indicator Group (1) has good accuracy, check its calibration at a minimum of every six months. Also, the timing indicator will need calibration if: A. It does not show 2000 30 R/MIN at (A) and 32.0 .2 DEG at (B), when the CALIBRATION CHECK-OPERATE Switch (C) is in the CALIBRATION CHECK position. With no input signal at (D) or (E), the reading at R/MIN location (A) must show three zeros (000). If four zeros (0000) show, it is an indication of a possible need for calibration of the unit. This error only is not reason enough to do a complete calibration procedure. It is also not necessary to do a complete calibration procedure if the reading at the DEG location (B) has a decimal point as shown, (00.0) in addition to the three zeros.B. Reading is different than (000) at either location (A) or (B).All calibrations can be done with the use of a small screwdriver, a frequency counter and

dc Voltages Conditions: 1. dc input voltage applied to POWER connector as shown.2. CALIBRATION CHECK/OPERATE switch in the OPERATE position.3. Neither transducer connected to indicator.4. TPI is reference for all voltages.Equipment Required: 6V3030 Digital Multimeterdc Input Voltages Waveforms Conditions: 1. dc power input voltage of 25 1 Volts.2. CALIBRATION CHECK/OPERATE switch in the CHECK position (can be held in CHECK position with tape).3. Neither transducer connected to indicator.4. TPI is reference for all waveforms.Equipment Required: dc oscilloscope (dual channel preferred). Waveform Time Relationships

VOLTAGES MAY VARY 10%, PULSE DURATIONS BY 20% EXCEPT 2.66 ms WHICH IS BASED ON A 12.000 kHz OSCILLATOR FREQ. (1C202). SIGNAL SOURCE IS INTERNAL CALIBRATOR. ALL TEST POINTS REFERENCED TO TP1.Waveform Time Relationships (enlarged scale)

VOLTAGES MAY VARY 10%, PULSE DURATIONS BY 20% EXCEPT 83.3 ?s AND 2.66 ms WHICH ARE EXACT BASED ON A 12.000 kHZ OSCILLATOR. (1C202) SIGNAL SOURCE IS INTERNAL CALIBRATOR. ALL TEST POINTS REFERENCED TO TP1.Disassembly Procedure

1 Remove six screws (1) from front panel (2), and remove panel (2) from case (3). Remove four screws (4) from the PC board, and also remove the locknuts from the two front panel switches (5) and (6). Carefully lift front panel (2) from PC (printed circuit) board (7).Calibration Procedure

To make sure the 6V3100 Timing Indicator Group (1) has good accuracy, check its calibration at a minimum of every six months. Also, the timing indicator will need calibration if: A. It does not show 2000 30 R/MIN at (A) and 32.0 .2 DEG at (B), when the CALIBRATION CHECK-OPERATE Switch (C) is in the CALIBRATION CHECK position. With no input signal at (D) or (E), the reading at R/MIN location (A) must show three zeros (000). If four zeros (0000) show, it is an indication of a possible need for calibration of the unit. This error only is not reason enough to do a complete calibration procedure. It is also not necessary to do a complete calibration procedure if the reading at the DEG location (B) has a decimal point as shown, (00.0) in addition to the three zeros.B. Reading is different than (000) at either location (A) or (B).All calibrations can be done with the use of a small screwdriver, a frequency counter and