Information injection-pump assembly

ZEXEL

101602-8350

1016028350

ISUZU

1156031970

1156031970

Rating:

Cross reference number

ZEXEL

101602-8350

1016028350

ISUZU

1156031970

1156031970

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9

Pump speed

r/min

725

725

725

Average injection quantity

mm3/st.

71

69.5

72.5

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

6.9+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

8

6.7

9.3

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

90

85

95

Fixing the lever

*

Rack limit

*

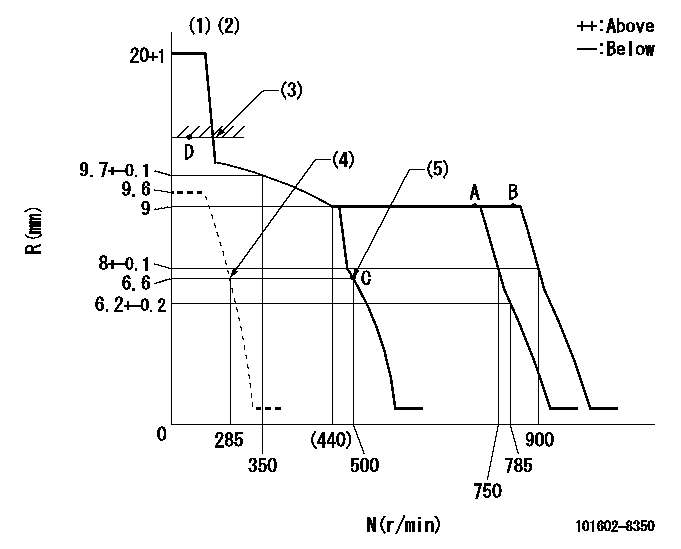

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

----------

K=11

----------

----------

K=11

----------

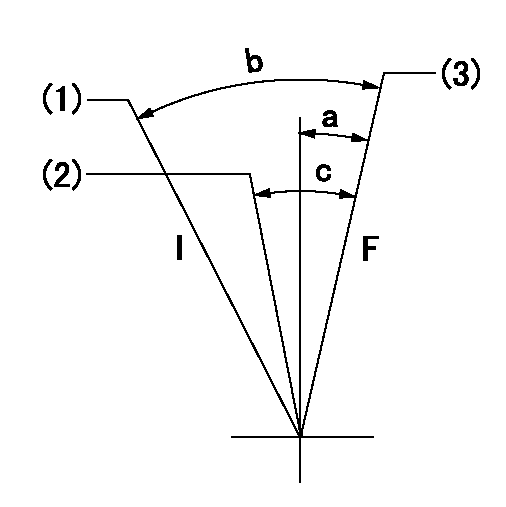

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)Set the pump speed at aa

(3)Set speed at bb (setting at delivery).

----------

aa=750r/min bb=900r/min

----------

a=2deg+-5deg b=15deg+-5deg c=6deg+-5deg

----------

aa=750r/min bb=900r/min

----------

a=2deg+-5deg b=15deg+-5deg c=6deg+-5deg

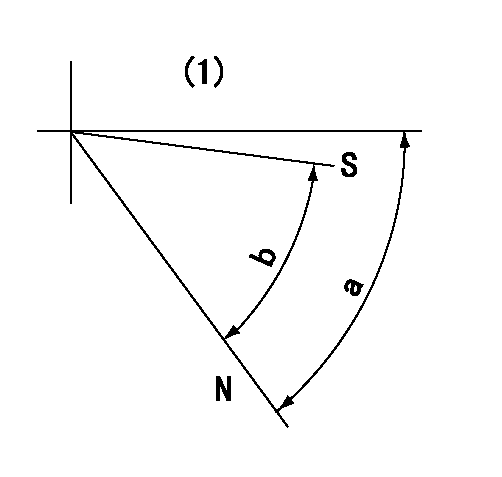

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)No return spring

----------

----------

a=66.5deg+-5deg b=53deg+-5deg

----------

----------

a=66.5deg+-5deg b=53deg+-5deg

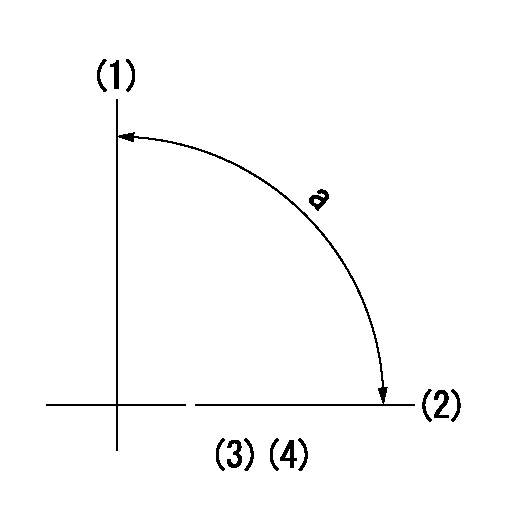

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'CC' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=14deg

----------

a=(90deg)

----------

aa=14deg

----------

a=(90deg)

Information:

December 9, 2005

U-389

A-289

D-306

O-325

Partsstock action only PRODUCT IMPROVEMENT PROGRAM FOR REMOVINGCERTAIN FUEL INJECTORS FROM DEALERS PARTS STOCK

7750 PI70111

The information supplied in this serviceletter may not be valid after the termination date of this program. Donot perform the work outlined in this Service Letter after the terminationdate without first contacting your Caterpillar product analyst.TERMINATION DATE

March 31, 2006PROBLEM

A machining error can cause the valve body tocrack through the high-pressure line. This crack can result in fuel inthe engine oil.ACTION REQUIRED

All 10R-0957 unit injectors within serial numberrange 848368-850132 should be removed from parts stock. All 10R-0960, 10R-0961,and 10R-0963 within serial number range 188029-188914 should be removedfrom parts stock.SERVICE CLAIM ALLOWANCES

Submit one claim for all 10R0957, 10R0960, 10R0961,and 10R0963 Injectors removed from parts stock.PARTS DISPOSITION

All dealers are to make sure the outsideof the shipping container is marked PI70111.***** U.S. and Canadian Dealers *****Return all 10R0957, 10R0960, 10R0961, and 10R0963Injectors that are removed from parts stock and a copy of the claim to:Caterpillar Inc.

Attn: Supplier Recovery PI70111

Service Claims Room

8201 N. University

Peoria, IL 61615***** All Other Dealers *****Handle the parts in accordance with your WarrantyBulletin on warranty parts handling.

U-389

A-289

D-306

O-325

Partsstock action only PRODUCT IMPROVEMENT PROGRAM FOR REMOVINGCERTAIN FUEL INJECTORS FROM DEALERS PARTS STOCK

7750 PI70111

The information supplied in this serviceletter may not be valid after the termination date of this program. Donot perform the work outlined in this Service Letter after the terminationdate without first contacting your Caterpillar product analyst.TERMINATION DATE

March 31, 2006PROBLEM

A machining error can cause the valve body tocrack through the high-pressure line. This crack can result in fuel inthe engine oil.ACTION REQUIRED

All 10R-0957 unit injectors within serial numberrange 848368-850132 should be removed from parts stock. All 10R-0960, 10R-0961,and 10R-0963 within serial number range 188029-188914 should be removedfrom parts stock.SERVICE CLAIM ALLOWANCES

Submit one claim for all 10R0957, 10R0960, 10R0961,and 10R0963 Injectors removed from parts stock.PARTS DISPOSITION

All dealers are to make sure the outsideof the shipping container is marked PI70111.***** U.S. and Canadian Dealers *****Return all 10R0957, 10R0960, 10R0961, and 10R0963Injectors that are removed from parts stock and a copy of the claim to:Caterpillar Inc.

Attn: Supplier Recovery PI70111

Service Claims Room

8201 N. University

Peoria, IL 61615***** All Other Dealers *****Handle the parts in accordance with your WarrantyBulletin on warranty parts handling.