Information injection-pump assembly

BOSCH

9 400 614 909

9400614909

ZEXEL

101602-7632

1016027632

ISUZU

1156028702

1156028702

Rating:

Service parts 101602-7632 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

5-15300-103-2

12.

Open Pre:MPa(Kqf/cm2)

14.7{150}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 614 909

9400614909

ZEXEL

101602-7632

1016027632

ISUZU

1156028702

1156028702

Zexel num

Bosch num

Firm num

Name

101602-7632

9 400 614 909

1156028702 ISUZU

INJECTION-PUMP ASSEMBLY

6BG1 K 14BE INJECTION PUMP ASSY PE6A PE

6BG1 K 14BE INJECTION PUMP ASSY PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

7.8

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

35.1

33.6

36.6

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

7.4+-0.5

Pump speed

r/min

390

390

390

Average injection quantity

mm3/st.

9.4

8.1

10.7

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Test data Ex:

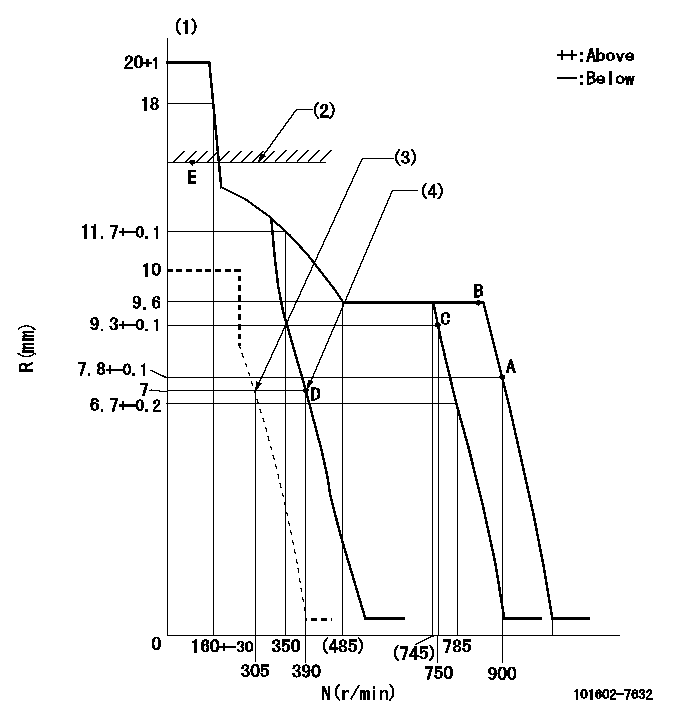

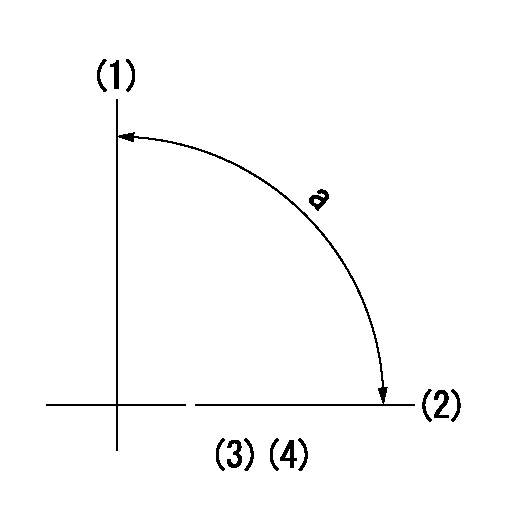

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT: RAL

(3)Set idle sub-spring

(4)Main spring setting

----------

K=8 RAL=13+-0.2mm

----------

----------

K=8 RAL=13+-0.2mm

----------

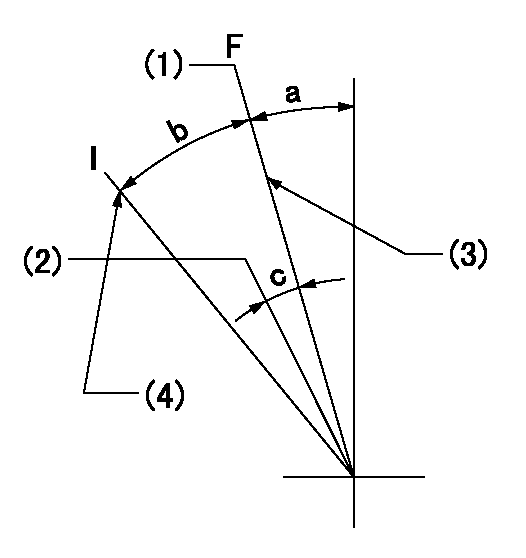

Speed control lever angle

F:Full speed

I:Idle

(1)Set the pump speed at aa

(2)Set the pump speed at bb.

(3)Stopper bolt setting

(4)Stopper bolt setting

----------

aa=900r/min bb=750r/min

----------

a=2deg+-5deg b=18deg+-5deg c=4deg+-5deg

----------

aa=900r/min bb=750r/min

----------

a=2deg+-5deg b=18deg+-5deg c=4deg+-5deg

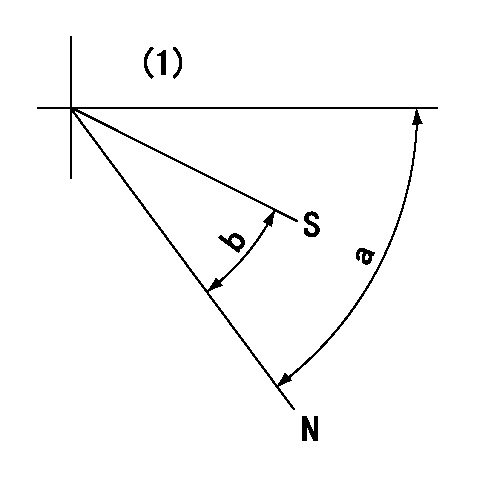

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)No return spring

----------

----------

a=66.5deg+-5deg b=53deg+-5deg

----------

----------

a=66.5deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'CC' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=18deg

----------

a=(90deg)

----------

aa=18deg

----------

a=(90deg)

Information:

TERMINATION DATE

30Sep2014

PROBLEM

The existing fuel injectors can experience solenoid valve poppet seizures or poppet binding within injector body due to excessive thermal expansion. If the existing fuel injector fails it can result in complaints of misfire and/or low power.

AFFECTED PRODUCT

Model Identification Number

AD55B JNW00101-00151, 153-155, 157-166, 168-199, 201-244, 246, 248-269, 272-275, 60250

PARTS NEEDED

Qty

Part Number Description

12 8S9191 BOLT

24 3565212 BOLT-12 POINT HD

12 3740751 INJECTOR GP-FUEL

In order to allow equitable parts availability to all participating dealers, please limit your initial parts order to not exceed 7% of dealership population. This is an initial order recommendation only, and the ultimate responsibility for ordering the total number of parts needed to satisfy the program lies with the dealer.

ACTION REQUIRED

A fuel injector is considered failed if the following troubleshooting Step 1 and Step 2 are completed and the problem is not resolved. Troubleshooting is not cover by this letter.

1. Ensure ECM software is current.

2. Perform the following procedures:

KENR5424 ? Troubleshooting

SENR9937 - Electronic Unit Injector ? Adjust

SENR9937 - Electronic Unit Injector - Test

3. Replace injector(s) as required.

If one or more injectors fail replace all injectors at the time of repair.

Refer to Disassembly and Assembly, RENR9217 for the removal and installation procedure of the unit injector.

8S-9191 Injector Hold Down Bolt must be replaced. Ensure that the proper torque is achieved, 55 +/- 10 Nm (41 +/- 7 lb ft).

356-5212 Rocker Arm Shaft Hold Down Bolts must be replaced. Ensure that proper torque procedure is adhered to.

1. Position rocker arm shaft assembly (4) , valve rocker arms (3) , and electronic unit injector rocker arms (1) as a unit with 124-2946 Lifting Bracket on the cylinder head.

Note: Apply clean engine oil to the underside of the bolt heads prior to installation.

2. Install bolts (2) and tighten to a torque of 55 +/- 5 Nm (41 +/- 4 lb ft). Tighten bolts (2) again to a torque of 55 +/- 5 Nm (41 +/- 4 lb ft). Turn bolts (2) for an additional 60 +/- 5 degrees. Tighten the bolts in the following sequence: 2, 3, 1, 4.

Image1

SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

0-6000 hrs,

0-18 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 16.0-hour job

If there has been a previous repair, part age/hours will apply. Retain a copy of the previous repair invoice in the dealer's records for audit purposes, and specify repair date and machine hours in the "Additional Comments" section of the warranty claim.

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Have questions with 101602-7632?

Group cross 101602-7632 ZEXEL

Isuzu

101602-7632

9 400 614 909

1156028702

INJECTION-PUMP ASSEMBLY

6BG1

6BG1