Information injection-pump assembly

ZEXEL

101602-7630

1016027630

ISUZU

1156028700

1156028700

Rating:

Cross reference number

ZEXEL

101602-7630

1016027630

ISUZU

1156028700

1156028700

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

7.8

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

35.1

33.6

36.6

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

7.4+-0.5

Pump speed

r/min

390

390

390

Average injection quantity

mm3/st.

9.4

8.1

10.7

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Test data Ex:

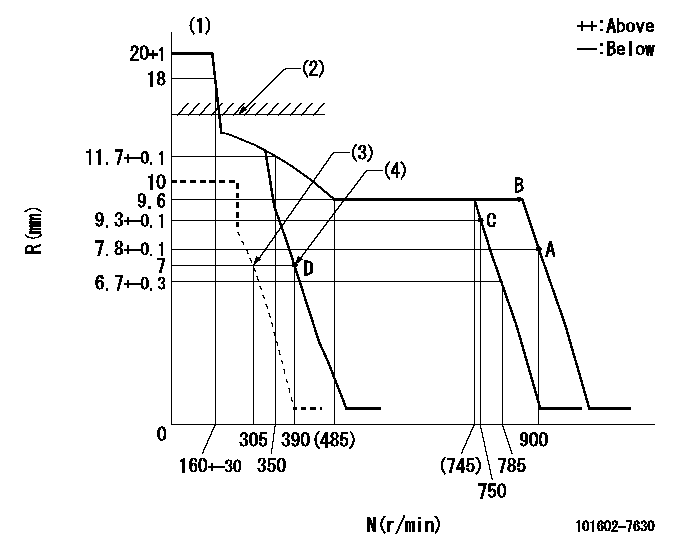

Governor adjustment

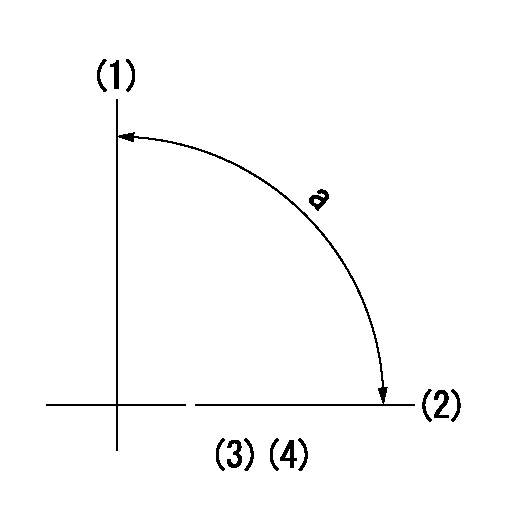

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK CAP: R1

(3)Set idle sub-spring

(4)Main spring setting

----------

K=8 R1=(17.5)mm

----------

----------

K=8 R1=(17.5)mm

----------

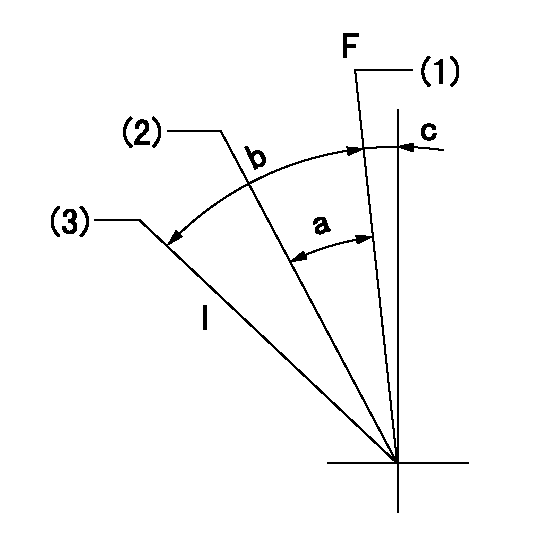

Speed control lever angle

F:Full speed

I:Idle

(1)Set the speed at aa, set the stopper bolt

(2)Set the pump speed at bb.

(3)Stopper bolt setting

----------

aa=900r/min bb=750r/min

----------

a=4deg+-5deg b=18deg+-5deg c=2deg+-5deg

----------

aa=900r/min bb=750r/min

----------

a=4deg+-5deg b=18deg+-5deg c=2deg+-5deg

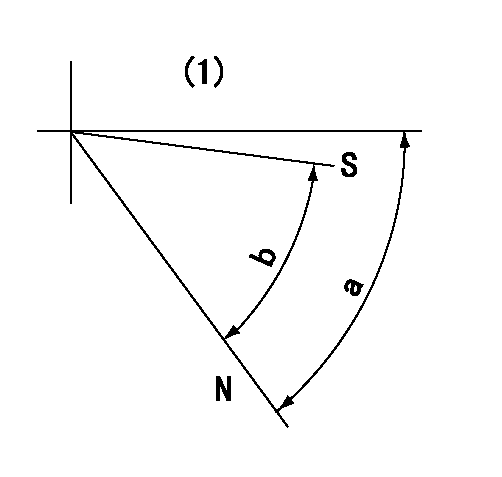

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)No return spring

----------

----------

a=66.5deg+-5deg b=53deg+-5deg

----------

----------

a=66.5deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'CC' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=18deg

----------

a=(90deg)

----------

aa=18deg

----------

a=(90deg)

Information:

Unsolder the leads quickly to prevent heat from damaging the diodes.

(b) Remove the rectifiers mounting screws, then remove the rectifier.

Removing statorInspection

Key Points For Inspection(1) Inspection Rectifier

With each diode, measure the resistance between the diode terminal and the heat sink. Measure the resistance with the tester's (+) probe applied to the diode terminal and with the tester's (-) probe applied to the diode terminal. If the resistance is infinite in both cases, there is an open circuit. If the resistance is close to zero in both cases, there is a short circuit. An open circuit or short circuit indicates a diode fault. Replace the rectifiers if any diode is faulty.Next, measure the resistance between the terminals of the leads that connect the rectifier to the stator coil for each of the diodes. If any measurement reveals an open circuit (infinite resistance) or a short circuit (near-zero resistance), replace the rectifier.

Inspecting rectifier(2) Inspecting Field Coil

(a) Check whether continuity exists between the rotor's slip rings. If continuity does not exist, the field coil is open-circuited and the rotor must be replaced.

Field coil continuity test(b) Check whether continuity exists between each slip ring and the rotor shaft (or core). If continuity exists, the field coil is grounded and the rotor must be replaced.

Field coil ground test(3) Inspecting Stator Coils

(a) Check whether continuity exists between the leads at the ends of each stator coil. If continuity does not exist between any coil's leads, there is an open circuit and the stator must be replaced.

Stator coil continuity test(b) Check whether continuity exists between each stator coil lead and the stator core. If continuity exists, the stator coil is grounded and the stator must be replaced.

Stator coil ground test(4) Inspecting Brushes

(a) Replace the brush if it is worn down to the wear limit line.

Inspecting Brush(b) Disconnect the brush lead wires at the soldered sections to remove the brushes and springs.

Removing brushes and springs(c) To install new brushes, press them into the brush holders as shown in the diagram, then solder the lead wires.

Installing brushesAssembly

Follow the reverse of disassembly and use the procedure below:(1) The rear bearing has a groove for the snap ring. Install the snap ring in this groove. Make sure its tab is in the deep portion of the groove.(2) When installing the new rear bearing, place it in position with the side that has a groove toward the slip rings of the rotor.(3) To install the rear bearing in the rear bracket, heat the rear bracket.(4) Before installing the rotor in the rear bracket, insert a wire-shaped tooling into the hole in the rear bracket to lift the brushes of the slip rings. Remove the tooling after the rotor has been installed in position.

Assembling alternatorInstallation

Perform installation by following the removal sequence in reverse. Key Points For Installation(1) Install the fan belt on the alternator and mount the alternator on the engine. Temporarily tighten all the bolts.(2) Insert a bar between the alternator and crankcase. Using the bar as leverage, move the alternator