Information injection-pump assembly

BOSCH

F 019 Z10 499

f019z10499

ZEXEL

101602-7610

1016027610

ISUZU

1156027940

1156027940

Rating:

Service parts 101602-7610 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

5-15300-103-2

12.

Open Pre:MPa(Kqf/cm2)

14.7(150)

15.

NOZZLE SET

Cross reference number

BOSCH

F 019 Z10 499

f019z10499

ZEXEL

101602-7610

1016027610

ISUZU

1156027940

1156027940

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

8.9

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

57.5

56

59

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

7.6+-0.5

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

9.4

8.1

10.7

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Test data Ex:

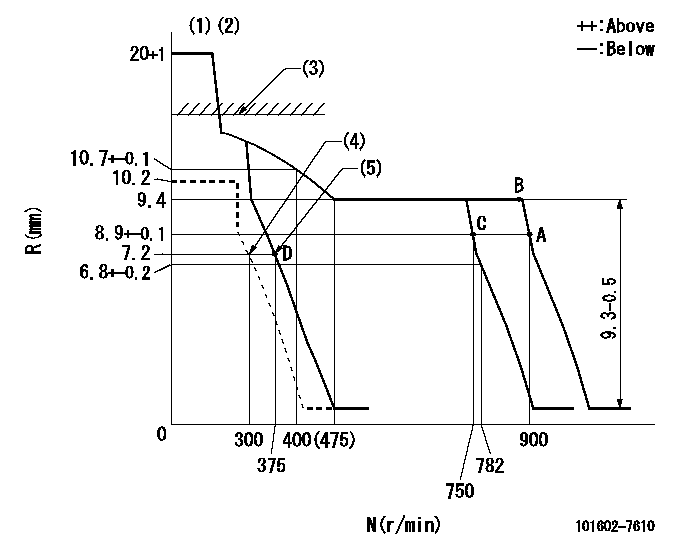

Governor adjustment

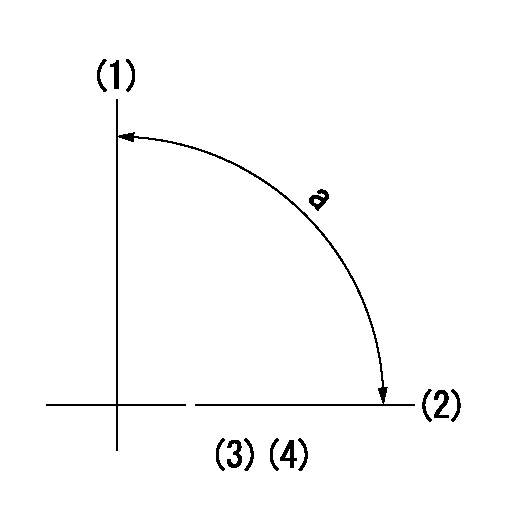

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK CAP: R1

(4)Set idle sub-spring

(5)Main spring setting

----------

K=7 R1=(17.5)mm

----------

----------

K=7 R1=(17.5)mm

----------

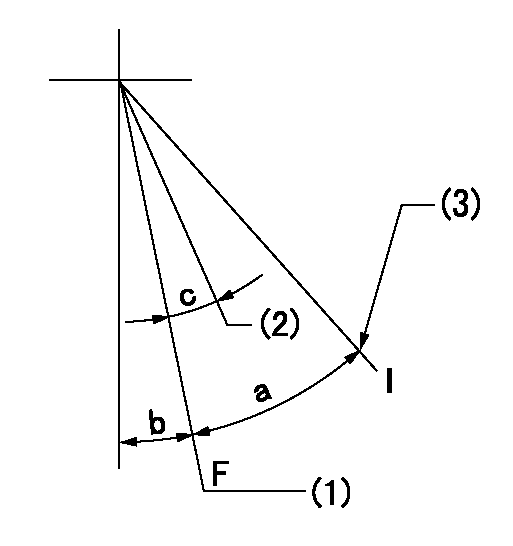

Speed control lever angle

F:Full speed

I:Idle

(1)Set the speed at aa, set the stopper bolt

(2)Set the pump speed at bb.

(3)Stopper bolt setting

----------

aa=900r/min bb=750r/min

----------

a=18deg+-5deg b=3deg+-5deg c=4deg+-5deg

----------

aa=900r/min bb=750r/min

----------

a=18deg+-5deg b=3deg+-5deg c=4deg+-5deg

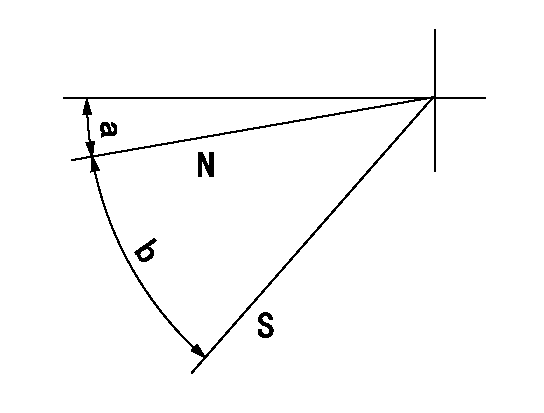

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=2.5deg+-5deg b=46deg+-5deg

----------

----------

a=2.5deg+-5deg b=46deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'CC' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=20deg

----------

a=(90deg)

----------

aa=20deg

----------

a=(90deg)

Information:

Overview of Lubrication System

Flow of oilOil Pump, Relief Valve, and Oil Pressure Switch

Disassembly

Removal sequence and points to check on oil pump(1) Oil filter(2) Oil pump(3) Gasket(4) Oil pump cover(5) Inner rotor(6) Outer rotor (the inner and outer rotors from a rotor assembly)(7) O-ring(8) Oil pump body(9) Relief valve(10) Oil pressure switch Key Points For Disassembly(1) Oil Pump

Remove the oil pump (parts (3) through (8) in the above illustration) as an assembly.

Removing oil pump(2) Oil Pressure Switch

Remove the switch using the Oil Pressure Switch Socket Wrench (MD998054).

Removing oil pressure switchInspection and Repair

(1) Oil Pump

(a) Using a thickness gauge, measure the clearance between the outer rotor and pump body. If the measurement exceeds the limit, replace the rotor assembly.Unit: mm (in.)

Measuring outer rotor-to-pump body clearance(b) Using a thickness gauge, measure the clearance between the outer rotor and the inner rotor. If the measurement exceeds the limit, replace the rotor assembly.Unit: mm (in.)

Measuring outer rotor-to-inner rotor clearance(c) Using a thickness edge and a thickness gauge, measure the clearance between the rotors and pump cover. If the measurement exceeds the limit, replace either the rotors or the pump body.Unit: mm (in.)

Measuring clearance between rotors and pump cover(2) Oil Pressure Switch

(a) Connect a tester (set to the ohm range) between the terminal and body of the oil pressure switch. There should be no continuity. If there is continuity, the switch is faulty and should be replaced.

Inspecting oil pressure switch(b) Insert a thin rod into the oil hole in the switch body. When the rod is then pushed in gently, there should be continuity between the switch body and terminal. If there is no continuity, the switch is faulty and should be replaced.(c) apply an air pressure of 49 kPa {0.5 kgf/cm2) (7.1 psi) to the switch through the oil hole. If there is continuity, the switch is normal. Simultaneously, check for air leakage. Any air leakage means that the diaphragm is broken and, therefore, the switch should be replaced.

Inspecting oil pressure switchAssembly

Point to note during reassembly of oil pumpPerform assembly by following the disassembly sequence in reverse: Key Points For Reassembly

Oil Pressure Switch

(a) Install the switch using the Oil Pressure Switch Socket Wrench (MD998054).(b) Before installation, apply sealant to the threads of the switch. (Use either Hermeseal H1 or ThreeBond 1104).

Installing Oil Pressure Switch

(a) Avoid applying sealant excessively to prevent it from reaching the end of the threads.(b Never tighten the switch to a torque exceeding specification.

Flow of oilOil Pump, Relief Valve, and Oil Pressure Switch

Disassembly

Removal sequence and points to check on oil pump(1) Oil filter(2) Oil pump(3) Gasket(4) Oil pump cover(5) Inner rotor(6) Outer rotor (the inner and outer rotors from a rotor assembly)(7) O-ring(8) Oil pump body(9) Relief valve(10) Oil pressure switch Key Points For Disassembly(1) Oil Pump

Remove the oil pump (parts (3) through (8) in the above illustration) as an assembly.

Removing oil pump(2) Oil Pressure Switch

Remove the switch using the Oil Pressure Switch Socket Wrench (MD998054).

Removing oil pressure switchInspection and Repair

(1) Oil Pump

(a) Using a thickness gauge, measure the clearance between the outer rotor and pump body. If the measurement exceeds the limit, replace the rotor assembly.Unit: mm (in.)

Measuring outer rotor-to-pump body clearance(b) Using a thickness gauge, measure the clearance between the outer rotor and the inner rotor. If the measurement exceeds the limit, replace the rotor assembly.Unit: mm (in.)

Measuring outer rotor-to-inner rotor clearance(c) Using a thickness edge and a thickness gauge, measure the clearance between the rotors and pump cover. If the measurement exceeds the limit, replace either the rotors or the pump body.Unit: mm (in.)

Measuring clearance between rotors and pump cover(2) Oil Pressure Switch

(a) Connect a tester (set to the ohm range) between the terminal and body of the oil pressure switch. There should be no continuity. If there is continuity, the switch is faulty and should be replaced.

Inspecting oil pressure switch(b) Insert a thin rod into the oil hole in the switch body. When the rod is then pushed in gently, there should be continuity between the switch body and terminal. If there is no continuity, the switch is faulty and should be replaced.(c) apply an air pressure of 49 kPa {0.5 kgf/cm2) (7.1 psi) to the switch through the oil hole. If there is continuity, the switch is normal. Simultaneously, check for air leakage. Any air leakage means that the diaphragm is broken and, therefore, the switch should be replaced.

Inspecting oil pressure switchAssembly

Point to note during reassembly of oil pumpPerform assembly by following the disassembly sequence in reverse: Key Points For Reassembly

Oil Pressure Switch

(a) Install the switch using the Oil Pressure Switch Socket Wrench (MD998054).(b) Before installation, apply sealant to the threads of the switch. (Use either Hermeseal H1 or ThreeBond 1104).

Installing Oil Pressure Switch

(a) Avoid applying sealant excessively to prevent it from reaching the end of the threads.(b Never tighten the switch to a torque exceeding specification.