Information injection-pump assembly

BOSCH

9 400 611 432

9400611432

ZEXEL

101602-7580

1016027580

ISUZU

1156028540

1156028540

Rating:

Service parts 101602-7580 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

5-15300-089-1

12.

Open Pre:MPa(Kqf/cm2)

18.1{185}

15.

NOZZLE SET

Include in #1:

101602-7580

as INJECTION-PUMP ASSEMBLY

Include in #2:

104749-1380

as _

Cross reference number

BOSCH

9 400 611 432

9400611432

ZEXEL

101602-7580

1016027580

ISUZU

1156028540

1156028540

Zexel num

Bosch num

Firm num

Name

101602-7580

9 400 611 432

1156028540 ISUZU

INJECTION-PUMP ASSEMBLY

6BD1 K 14BE INJECTION PUMP ASSY PE6A PE

6BD1 K 14BE INJECTION PUMP ASSY PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.2

3.15

3.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

8.9

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

73

71.5

74.5

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

5.9+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

9.8

8.5

11.1

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Test data Ex:

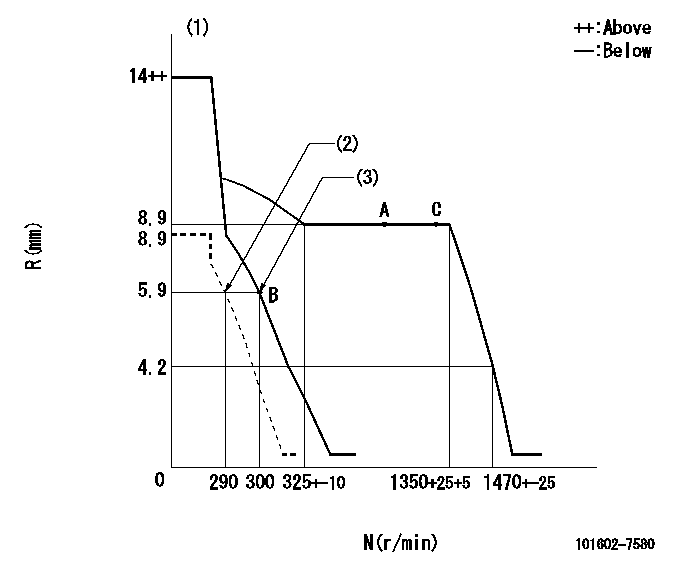

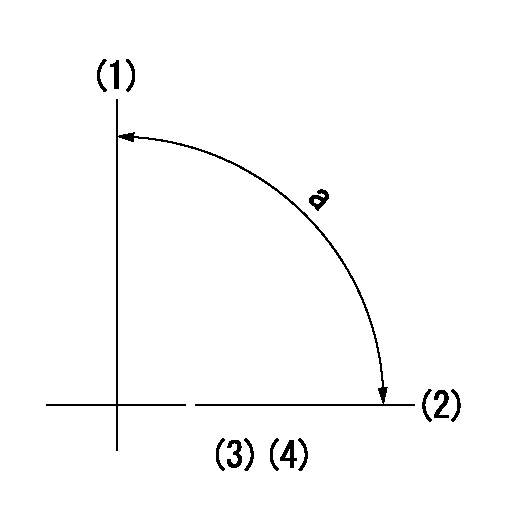

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Set idle sub-spring

(3)Main spring setting

----------

K=4

----------

----------

K=4

----------

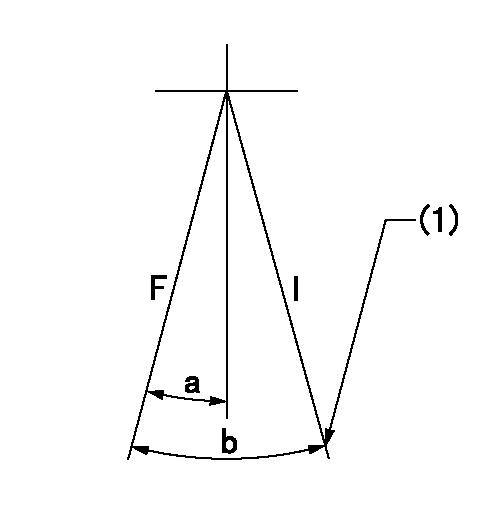

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=7deg+-5deg b=29deg+-5deg

----------

----------

a=7deg+-5deg b=29deg+-5deg

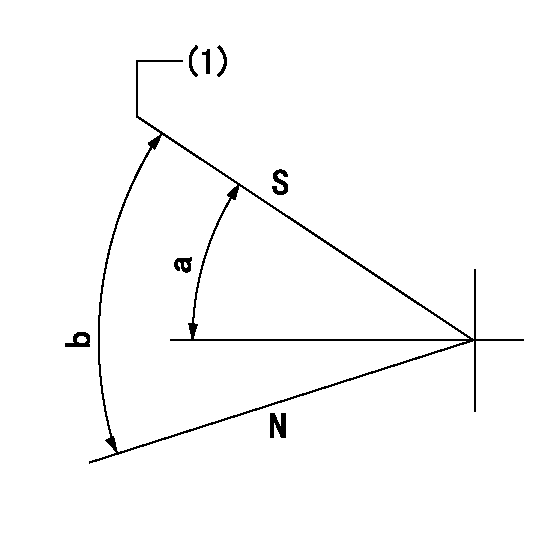

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa and rack position bb (to be sealed at delivery)

----------

aa=0r/min bb=1-0.2mm

----------

a=32deg+-5deg b=(55deg)

----------

aa=0r/min bb=1-0.2mm

----------

a=32deg+-5deg b=(55deg)

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'CC' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=23deg

----------

a=(90deg)

----------

aa=23deg

----------

a=(90deg)

Information:

When fuel has stopped flowing out, turn the crankshaft slightly in the reverse direction such that fuel flows out. Then, slowly turn the crankshaft clockwise again to more accurately verify the point at which fuel stops flowing out.

End of fuel flow(c) If the IT mark on the crankshaft pulley and the mark on the gear case are aligned when fuel stops flowing out the injection timing is normal.

Timing marks(3) Adjustment

(a) If the injection timing is out of specification, make adjustments by increasing or decreasing the thickness of the injection pump's mounting shim. A change of 0.1 mm in the shim thickness yields a change of approximately 1° in the injection timing.

Injection timing adjusting shim(b) Increasing the shim thickness retards the injection timing, and decreasing the shim thickness advances it. Shims come in 9 different thicknesses from 0.2 mm (0.008 in.) to 1.0 mm (0.039 in.) at intervals of 0.1 mm (0.004 in.). The thickness is not indicated on the shim, so any shim should be measured with a vernier caliper before being used.

Before using any shim, apply sealant to both sides to prevent oil leakage.

(c) After making adjustments, check the injection timing is correct.(d) Close the cock on the fuel filter, then fit the delivery valve spring and injection pipe in their original positions.

Adjusting injection timingAdjusting Idle Speed

(1) Preparation for Adjustment

(a) Warm up the engine unit the coolant reaches a temperature of 60°C (140°F) or higher.(b) Make sure the valve clearances, injection timing, and injectors are normal.(2) Adjusting Low-Idle Speed

Loosen the locknut on the idling set bolt, turn the bolt to achieve the specified low-idle speed (1000 25min-1), then tighten the lock nut to hold the bolt in that position.(3) Adjusting No-Load Maximum Speed

Loosen the lock nut on the high-speed set bolt, turn the bolt to achieve the specified no-load maximum speed (2600 +30-10 min-1), then tighten the lock nut to hold the bolt in that position.

Adjusting idle speedAdjusting Fan Belt Tension

(1) Press the fan belt with the specified force mid-way between the alternator pulley and crankshaft pulley, and observe the extent of deflection.Unit: mm (in.) (2) If the extent of deflection is out of specification, loosen the adjusting bolt and adjust the fan belt tension by moving the alternator. Retighten the adjusting bolt securely.

Adjusting fan belt tensionRunning in the Engine

After an overhaul, the engine should be tested and inspected on a dynamometer. This operation serves to run in the engine's major moving parts.Starting the Engine

(1) Before starting the engine, check the coolant, engine oil and fuel levels and bleed all air out of the fuel and cooling systems.(2) Without supplying fuel to the engine, crank the engine for about 10 seconds to permit oil to circulate through it.(3) Move the speed control lever slightly in the fuel-increase direction. (Do not move the lever to the full-injection position.) Then, turn the starter switch to the START position to start the engine.(4) Once the engine has started, set it to the low-idle speed using the speed control lever.Inspection after

End of fuel flow(c) If the IT mark on the crankshaft pulley and the mark on the gear case are aligned when fuel stops flowing out the injection timing is normal.

Timing marks(3) Adjustment

(a) If the injection timing is out of specification, make adjustments by increasing or decreasing the thickness of the injection pump's mounting shim. A change of 0.1 mm in the shim thickness yields a change of approximately 1° in the injection timing.

Injection timing adjusting shim(b) Increasing the shim thickness retards the injection timing, and decreasing the shim thickness advances it. Shims come in 9 different thicknesses from 0.2 mm (0.008 in.) to 1.0 mm (0.039 in.) at intervals of 0.1 mm (0.004 in.). The thickness is not indicated on the shim, so any shim should be measured with a vernier caliper before being used.

Before using any shim, apply sealant to both sides to prevent oil leakage.

(c) After making adjustments, check the injection timing is correct.(d) Close the cock on the fuel filter, then fit the delivery valve spring and injection pipe in their original positions.

Adjusting injection timingAdjusting Idle Speed

(1) Preparation for Adjustment

(a) Warm up the engine unit the coolant reaches a temperature of 60°C (140°F) or higher.(b) Make sure the valve clearances, injection timing, and injectors are normal.(2) Adjusting Low-Idle Speed

Loosen the locknut on the idling set bolt, turn the bolt to achieve the specified low-idle speed (1000 25min-1), then tighten the lock nut to hold the bolt in that position.(3) Adjusting No-Load Maximum Speed

Loosen the lock nut on the high-speed set bolt, turn the bolt to achieve the specified no-load maximum speed (2600 +30-10 min-1), then tighten the lock nut to hold the bolt in that position.

Adjusting idle speedAdjusting Fan Belt Tension

(1) Press the fan belt with the specified force mid-way between the alternator pulley and crankshaft pulley, and observe the extent of deflection.Unit: mm (in.) (2) If the extent of deflection is out of specification, loosen the adjusting bolt and adjust the fan belt tension by moving the alternator. Retighten the adjusting bolt securely.

Adjusting fan belt tensionRunning in the Engine

After an overhaul, the engine should be tested and inspected on a dynamometer. This operation serves to run in the engine's major moving parts.Starting the Engine

(1) Before starting the engine, check the coolant, engine oil and fuel levels and bleed all air out of the fuel and cooling systems.(2) Without supplying fuel to the engine, crank the engine for about 10 seconds to permit oil to circulate through it.(3) Move the speed control lever slightly in the fuel-increase direction. (Do not move the lever to the full-injection position.) Then, turn the starter switch to the START position to start the engine.(4) Once the engine has started, set it to the low-idle speed using the speed control lever.Inspection after

Have questions with 101602-7580?

Group cross 101602-7580 ZEXEL

Isuzu

101602-7580

9 400 611 432

1156028540

INJECTION-PUMP ASSEMBLY

6BD1

6BD1