Information injection-pump assembly

ZEXEL

101602-7460

1016027460

ISUZU

1156027840

1156027840

Rating:

Cross reference number

ZEXEL

101602-7460

1016027460

ISUZU

1156027840

1156027840

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.4

3.35

3.45

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

8.4

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

74.8

73.3

76.3

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

5.6+-0.5

Pump speed

r/min

340

340

340

Average injection quantity

mm3/st.

9.4

8.1

10.7

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Test data Ex:

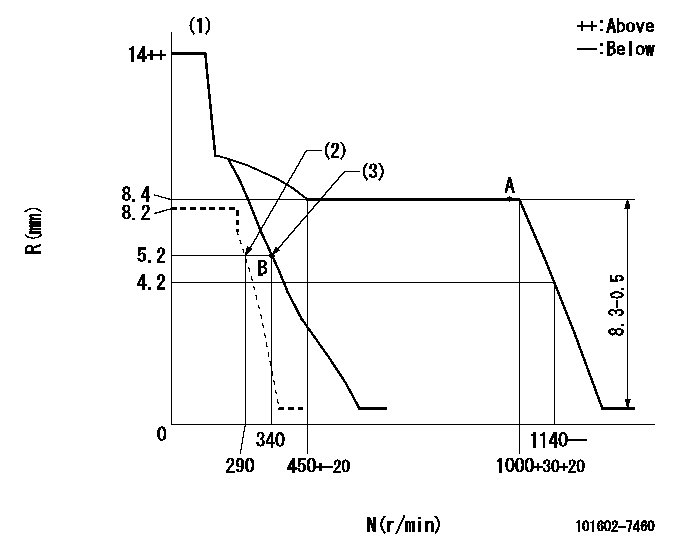

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Set idle sub-spring

(3)Main spring setting

----------

K=14

----------

----------

K=14

----------

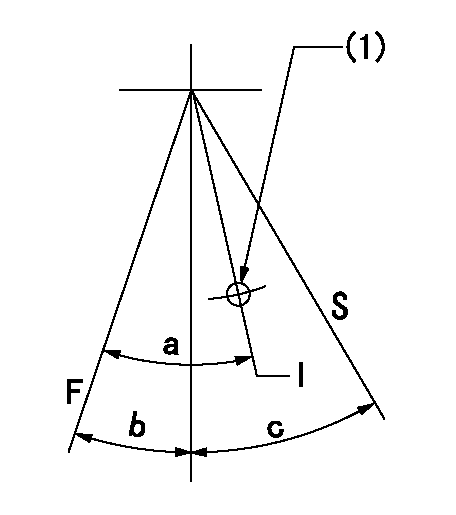

Speed control lever angle

F:Full speed

I:Idle

S:Stop

(1)Use the hole at R = aa

----------

aa=70mm

----------

a=20deg+-5deg b=3deg+-5deg c=35deg+-3deg

----------

aa=70mm

----------

a=20deg+-5deg b=3deg+-5deg c=35deg+-3deg

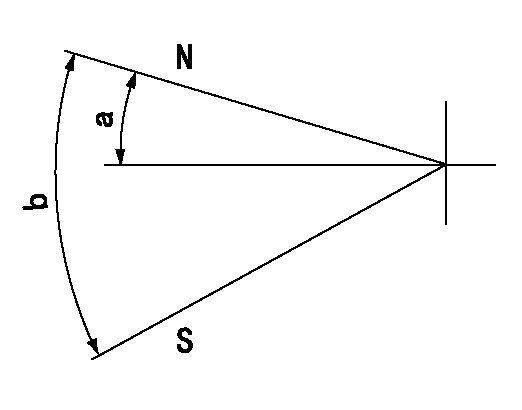

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=12deg+-5deg b=46deg+-5deg

----------

----------

a=12deg+-5deg b=46deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'CC' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=16deg

----------

a=(100deg)

----------

aa=16deg

----------

a=(100deg)

Information:

Unit: mm (in.)

Measuring clearance between piston ring and groove(b) If the clearance still exceeds the limit after new piston rings have been installed, replace the piston.(3) Clearance between ends of piston ring Put the piston ring in a gauge or in the bore in a new cylinder block and measure the clearance between the ends of the ring with a feeler gauge as shown in the illustration. If the gauge as shown in the illustration. If the clearance exceeds the limit, replace all the rings.

Measuring clearance between ends of piston ring Put the piston ring in the gauge or cylinder squarely with the piston.

Unit: mm (in.)(4) Clearance between piston pin and piston Measure the diameter of the piston pin and the bore in the piston for the pin as shown in the illustration to find the clearance. If the clearance exceeds the limit, replace the piston or pin whichever is badly worn.

Unit: mm (in.)

Measuring piston pin and bore in piston for pin2. Connecting rods Check the connecting rod for bend or twist as follows:(a) Measure "C" and "l". If "C" exceeds 0.05 mm (0.0020 in.) per 100 mm (3.94 in.) of "l", straighten the connecting rod with a press.

Unit: mm (in.)

Checking connecting rod for bend or twist(b) Generally, a connecting rod aligner is used to check the connecting rod for bend or twist. To check the rod for bend, install the cap to the connecting rod and tighten the cap nuts to the specified torque.

Check connecting rod on a connecting rod aligner(c) To check the connecting rod fitted to the piston for bend, put the connecting rod and piston on the surface plate as shown in the illustration, insert a round bear having a diameter equal to that of the crankpin into the bore in the big end of the rod and measure "A" and "B" with a dial indicator. Subtract "A" from "B" to find the bend ("C").

Checking connecting rod for bend with a dial indicator 3. Crankshaft(1) Clearance between crankpin and connecting rod bearing(a) Install the bearing (upper and lower halves) and cap to the big end of the connecting rod and tighten the cap nuts to the specified torque. Measure the bore in the bearing for crankpin as shown in the illustration. (b) Measure the diameter of the crankpin as shown in the illustration to find the clearance between the crankpin and connecting rod bearing.

Unit: mm (in.)

Measuring diameter of crankpin(c) If the clearance exceeds the limit, install a new bearing and check the clearance again. (d) If the clearance still exceeds the limit, grind the crankpin to 0.25 mm (0.0098 in.), 0.50 mm (0.0197 in.) or 0.75 mm (0.0295 in.) undersize and use undersize connecting rod bearing.Crankpin undersizes

Unit: mm (in.)

a) Grind all the crankpins of one crankshaft to the same undersize.b) Finish the crankpin fillets to a radius of 2.5 mm (0.098 in.).

Crankpin fillet radius(2) Clearance between journal and main bearing (a) Install the main bearing (upper and lower halves) and cap to the cylinder