Information injection-pump assembly

BOSCH

F 019 Z10 265

f019z10265

ZEXEL

101602-7440

1016027440

ISUZU

1156018200

1156018200

Rating:

Service parts 101602-7440 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-104-2

12.

Open Pre:MPa(Kqf/cm2)

18.1{185}

15.

NOZZLE SET

Cross reference number

BOSCH

F 019 Z10 265

f019z10265

ZEXEL

101602-7440

1016027440

ISUZU

1156018200

1156018200

Zexel num

Bosch num

Firm num

Name

F 019 Z10 265

1156018200 ISUZU

INJECTION-PUMP ASSEMBLY

6BG1 * K 14BE PE6A PE

6BG1 * K 14BE PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.5

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

67.5

66

69

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

6.1+-0.5

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

8.5

7.1

9.9

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

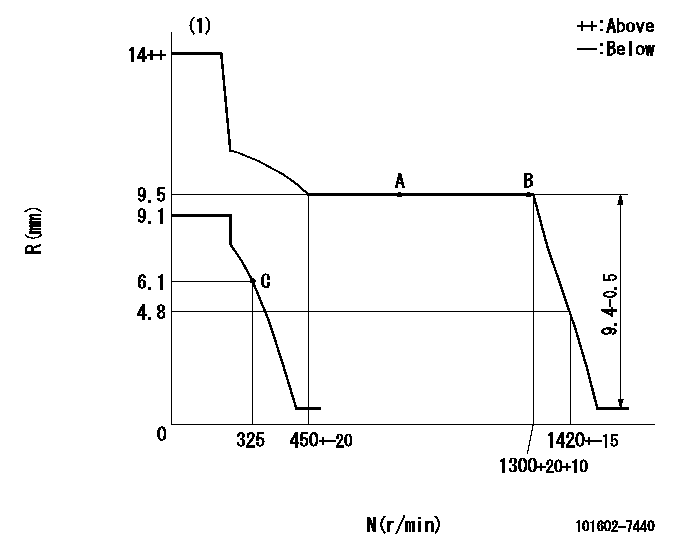

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

----------

K=12

----------

----------

K=12

----------

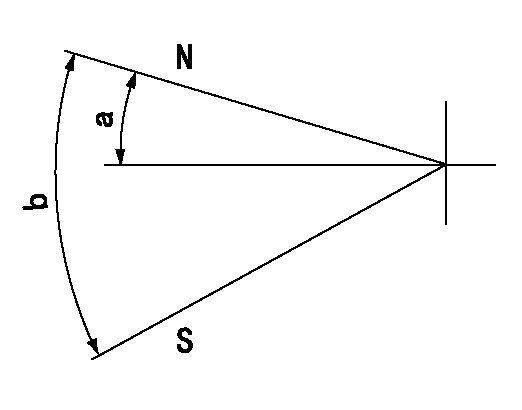

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=9deg+-5deg b=28deg+-5deg

----------

----------

a=9deg+-5deg b=28deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=12deg+-5deg b=46deg+-5deg

----------

----------

a=12deg+-5deg b=46deg+-5deg

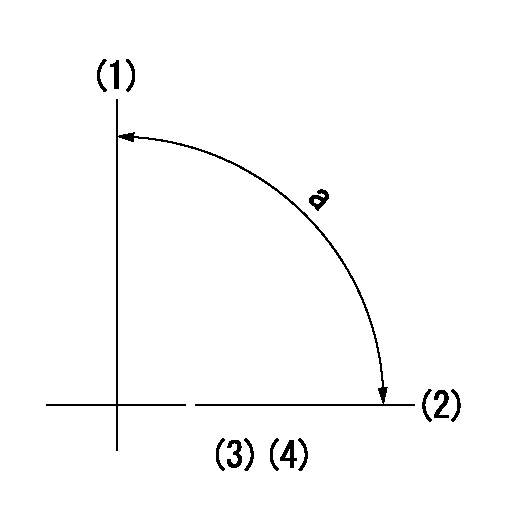

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'CC' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=20deg

----------

a=(90deg)

----------

aa=20deg

----------

a=(90deg)

Information:

COMPRESSION PRESSURE MEASUREMENT

1. Inspection Check to make sure -(1) The crankcase oil level is correct, and the air cleaner, starter and battery are all in normal condition.(2) The engine is at the normal operating temperature.2. Measurement (1) Move the control lever to a position for shutting off fuel supply.(2) Remove all glow plugs from the engine. Install the compression gauge and adapter (ST332270) combination to a cylinder on which the compression pressure is to be measured.

Compression gauge and adaptor

Measuring compression pressure(3) Turn the engine with the starter and read the gauge pressure at the instant the gauge pointer comes to stop.(4) If the gauge reading is below the limit, overhaul the engine.

a) Be sure to measure the compression pressure on all cylinders.b) The compression pressure varies with change of engine rpm. This makes it necessary to check engine rpm at the time of measuring the compression pressure.

a) It is important to measure the compression pressure at regular intervals to obtain the data on the gradual change of the compression pressure.b) The compression pressure would be slightly higher than the standard in a new or overhauled engine owing to break-in of the piston rings, valve seats, etc. It drops as the engine components wear down.

TROUBLESHOOTING

1. GeneralThe diagnosis of troubles, especially those caused by a faulty fuel injection pump or injection nozzles, or low compression pressure, can be difficult. It requires a careful inspection to determine not which item is the cause, but how many causes are contributing to the cause. Several causes may be contributing to a single trouble.On the following pages, there are troubleshooting charts on which engine troubles can be traced to their causes. Each chart has items to be verified ahead and suggested inspection procedure.Diesel engines exhibit some marked characteristics during operation. Knowing these characteristics will help minimize time lost in tracing engine troubles to their source. Following are the characteristics of diesel engines you should know about for diagnosis:* Combustion know (diesel knock)* Some black exhaust smoke (when the engine picks up load)* Vibration (due to high compression pressure and high torque)* Hunting (when the engine speed is quickly decreased)* Some white exhaust smoke (when the engine is cold, or shortly after the engine has been started) 2. Engine troubleshooting Problem 1: Hard starting(1) Items to be checked for ahead* Clogged air cleaner* Wrong oil grade for weather conditions * Poor quality fuel* Low cranking speed(2) Inspection procedure Problem 2: Fuel knockMore or less fuel knock occurs in diesel engines. This may be caused either by an excessively large delay period or by a too fast rate of fuel injection.(1) Items to be checked for ahead* Clogged air cleaner* Poor quality fuel(2) Inspection procedure Problem 3: Overheating(1) Items to be checked for aheadOverheating might also be caused by abnormal operating conditions. If the engine is overheating but its cooling system is not contributing to this trouble, it is necessary to check the difference between the ambient temperature and coolant temperature when the engine is in

1. Inspection Check to make sure -(1) The crankcase oil level is correct, and the air cleaner, starter and battery are all in normal condition.(2) The engine is at the normal operating temperature.2. Measurement (1) Move the control lever to a position for shutting off fuel supply.(2) Remove all glow plugs from the engine. Install the compression gauge and adapter (ST332270) combination to a cylinder on which the compression pressure is to be measured.

Compression gauge and adaptor

Measuring compression pressure(3) Turn the engine with the starter and read the gauge pressure at the instant the gauge pointer comes to stop.(4) If the gauge reading is below the limit, overhaul the engine.

a) Be sure to measure the compression pressure on all cylinders.b) The compression pressure varies with change of engine rpm. This makes it necessary to check engine rpm at the time of measuring the compression pressure.

a) It is important to measure the compression pressure at regular intervals to obtain the data on the gradual change of the compression pressure.b) The compression pressure would be slightly higher than the standard in a new or overhauled engine owing to break-in of the piston rings, valve seats, etc. It drops as the engine components wear down.

TROUBLESHOOTING

1. GeneralThe diagnosis of troubles, especially those caused by a faulty fuel injection pump or injection nozzles, or low compression pressure, can be difficult. It requires a careful inspection to determine not which item is the cause, but how many causes are contributing to the cause. Several causes may be contributing to a single trouble.On the following pages, there are troubleshooting charts on which engine troubles can be traced to their causes. Each chart has items to be verified ahead and suggested inspection procedure.Diesel engines exhibit some marked characteristics during operation. Knowing these characteristics will help minimize time lost in tracing engine troubles to their source. Following are the characteristics of diesel engines you should know about for diagnosis:* Combustion know (diesel knock)* Some black exhaust smoke (when the engine picks up load)* Vibration (due to high compression pressure and high torque)* Hunting (when the engine speed is quickly decreased)* Some white exhaust smoke (when the engine is cold, or shortly after the engine has been started) 2. Engine troubleshooting Problem 1: Hard starting(1) Items to be checked for ahead* Clogged air cleaner* Wrong oil grade for weather conditions * Poor quality fuel* Low cranking speed(2) Inspection procedure Problem 2: Fuel knockMore or less fuel knock occurs in diesel engines. This may be caused either by an excessively large delay period or by a too fast rate of fuel injection.(1) Items to be checked for ahead* Clogged air cleaner* Poor quality fuel(2) Inspection procedure Problem 3: Overheating(1) Items to be checked for aheadOverheating might also be caused by abnormal operating conditions. If the engine is overheating but its cooling system is not contributing to this trouble, it is necessary to check the difference between the ambient temperature and coolant temperature when the engine is in