Information injection-pump assembly

BOSCH

9 400 614 848

9400614848

ZEXEL

101602-4742

1016024742

ISUZU

1156021542

1156021542

Rating:

Service parts 101602-4742 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-161-0

12.

Open Pre:MPa(Kqf/cm2)

22.1(225)

15.

NOZZLE SET

Include in #1:

101602-4742

as INJECTION-PUMP ASSEMBLY

Include in #2:

104749-1480

as _

Cross reference number

BOSCH

9 400 614 848

9400614848

ZEXEL

101602-4742

1016024742

ISUZU

1156021542

1156021542

Zexel num

Bosch num

Firm num

Name

9 400 614 848

1156021542 ISUZU

INJECTION-PUMP ASSEMBLY

6SA1T * K 14BF PE6AD PE

6SA1T * K 14BF PE6AD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.7

4.65

4.75

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.3

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

123.6

122.6

124.6

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

5.6+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

9

7

11

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

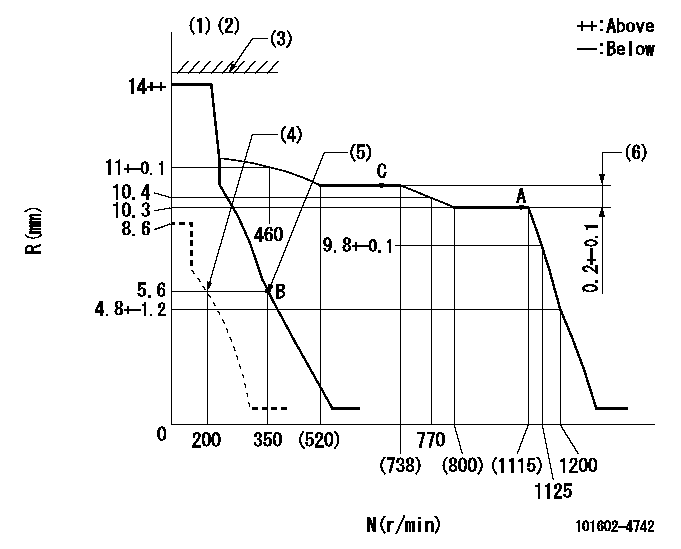

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT not operating.

(4)Set idle sub-spring

(5)Main spring setting

(6)Rack difference between N = N1 and N = N2

----------

K=14 N1=1100r/min N2=700r/min

----------

----------

K=14 N1=1100r/min N2=700r/min

----------

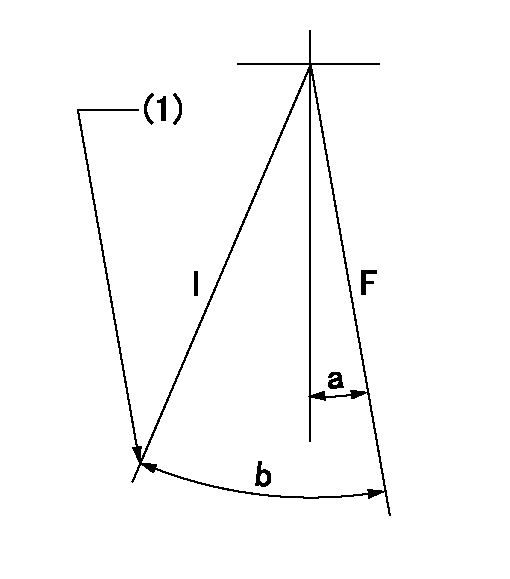

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=10deg+-5deg b=25deg+-5deg

----------

----------

a=10deg+-5deg b=25deg+-5deg

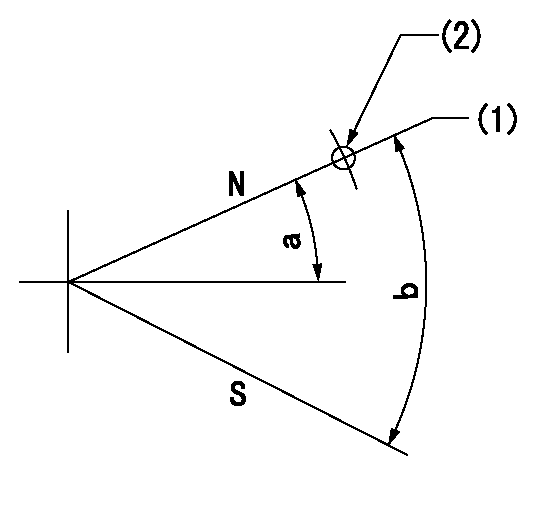

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

(2)Use the hole at R = aa

----------

aa=60mm

----------

a=19deg+-5deg b=53deg+-5deg

----------

aa=60mm

----------

a=19deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of coupling's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=20deg

----------

a=(40deg)

----------

aa=20deg

----------

a=(40deg)

Information:

Operation

At all speeds the rotor blades are kept in contact with the bore of the body by centrifugal force, assisted by the hydraulic action of the oil beneath the blades. When the rotor turns, the spaces between the blades vary because of the eccentric mounting of the rotor in the exhauster body. As a blade passes the inlet port, the space between it and the following blade is increasing and air is drawn from the vacuum reservoir. This air is then compressed and expelled, with the lubricating oil, through the outlet port to the engine timing case.Periodic Inspections and Preventive Maintenance

Every 5,000 miles (7,500 km) or 250 Hours

Check the vacuum lines and fittings. (Vacuum leakage may occur through the line, or reservoir mounted non-return valve if the valve seat is dirty or pitted). Examine the exhauster for evidence of oil leakage, particularly at end cover joints, and at shaft oil seal.Check the oil supply line for leaks at fittings and connections.Check the mounting and end cover nuts and bolts for tightness.Every 60,000 Miles (90,000 km) or 2,500 Hours

Remove and dismantle exhauster, thoroughly clean all parts and inspect for wear and damage. Repair or replace the exhauster with a Factory Replacement Unit.Removal

Disconnect oil and vacuum pipes at the exhauster and plug ends to prevent the entry of foreign matter.

Q2 1. Distance Piece2. ExhausterUndo the four nuts that secure the exhauster to the timing case, and withdraw the unit complete with its driving gear, from the studs (Fig. Q.2).Dismantling

Remove the two half-round thrust plates which locate the drive gear on the front of exhauster shaft.Remove drive gear.Mark the end covers in relation to the body to correct location on re-assembly.Unscrew four setscrews and remove rear end cover with rubber sealing ring.Mark the blades in relation to the rotor.Withdraw the rotor and fibre blades from the body.Unscrew four socket headed screws, and remove drive end cover, with joint or rubber ring.Remove rear end cover circlip, blanking disc, and rubber oil seal ring, if fitted. Further dismantling of the rotor assembly need be undertaken only if, after inspection, it is found necessary to renew the bearing or shaft collar.Cleaning and Inspection Cleaning

Wash the roller bearing, where fitted, in thin flushing oil or white spirit and blow dry with compressed air. Spinning the bearing with compressed air should be avoided, otherwise damage to the rollers and race will occur.Wash the remaining components in cleaning solvent, and clear the rotor and drive end cover oilways with compressed air.Inspection of Parts

Examine the roller bearings, where fitted, for discolouration, wear, pitting and cracked races. Rotate slowly to examine for roughness. To renew, see "Overhaul" Section. Premature failure may have been caused by shortage of oil.Examine plain bearing(s) for excessive wear. To renew, see "Overhaul" Section.Inspect rotor and shaft for cracks and damage, and the shaft seal collar for wear. To renew collar, see "Overhaul" Section.Check fit of blades in rotor slots, replace any worn or damaged blades.Examine the seal(s) carefully to see that the sealing edge

At all speeds the rotor blades are kept in contact with the bore of the body by centrifugal force, assisted by the hydraulic action of the oil beneath the blades. When the rotor turns, the spaces between the blades vary because of the eccentric mounting of the rotor in the exhauster body. As a blade passes the inlet port, the space between it and the following blade is increasing and air is drawn from the vacuum reservoir. This air is then compressed and expelled, with the lubricating oil, through the outlet port to the engine timing case.Periodic Inspections and Preventive Maintenance

Every 5,000 miles (7,500 km) or 250 Hours

Check the vacuum lines and fittings. (Vacuum leakage may occur through the line, or reservoir mounted non-return valve if the valve seat is dirty or pitted). Examine the exhauster for evidence of oil leakage, particularly at end cover joints, and at shaft oil seal.Check the oil supply line for leaks at fittings and connections.Check the mounting and end cover nuts and bolts for tightness.Every 60,000 Miles (90,000 km) or 2,500 Hours

Remove and dismantle exhauster, thoroughly clean all parts and inspect for wear and damage. Repair or replace the exhauster with a Factory Replacement Unit.Removal

Disconnect oil and vacuum pipes at the exhauster and plug ends to prevent the entry of foreign matter.

Q2 1. Distance Piece2. ExhausterUndo the four nuts that secure the exhauster to the timing case, and withdraw the unit complete with its driving gear, from the studs (Fig. Q.2).Dismantling

Remove the two half-round thrust plates which locate the drive gear on the front of exhauster shaft.Remove drive gear.Mark the end covers in relation to the body to correct location on re-assembly.Unscrew four setscrews and remove rear end cover with rubber sealing ring.Mark the blades in relation to the rotor.Withdraw the rotor and fibre blades from the body.Unscrew four socket headed screws, and remove drive end cover, with joint or rubber ring.Remove rear end cover circlip, blanking disc, and rubber oil seal ring, if fitted. Further dismantling of the rotor assembly need be undertaken only if, after inspection, it is found necessary to renew the bearing or shaft collar.Cleaning and Inspection Cleaning

Wash the roller bearing, where fitted, in thin flushing oil or white spirit and blow dry with compressed air. Spinning the bearing with compressed air should be avoided, otherwise damage to the rollers and race will occur.Wash the remaining components in cleaning solvent, and clear the rotor and drive end cover oilways with compressed air.Inspection of Parts

Examine the roller bearings, where fitted, for discolouration, wear, pitting and cracked races. Rotate slowly to examine for roughness. To renew, see "Overhaul" Section. Premature failure may have been caused by shortage of oil.Examine plain bearing(s) for excessive wear. To renew, see "Overhaul" Section.Inspect rotor and shaft for cracks and damage, and the shaft seal collar for wear. To renew collar, see "Overhaul" Section.Check fit of blades in rotor slots, replace any worn or damaged blades.Examine the seal(s) carefully to see that the sealing edge