Information injection-pump assembly

BOSCH

9 400 614 847

9400614847

ZEXEL

101602-4700

1016024700

ISUZU

1156021260

1156021260

Rating:

Service parts 101602-4700 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

8.

_

9.

_

11.

Nozzle and Holder

1-15300-104-1

12.

Open Pre:MPa(Kqf/cm2)

18.1(185)

15.

NOZZLE SET

Include in #1:

101602-4700

as INJECTION-PUMP ASSEMBLY

Include in #2:

104749-1491

as _

Cross reference number

BOSCH

9 400 614 847

9400614847

ZEXEL

101602-4700

1016024700

ISUZU

1156021260

1156021260

Zexel num

Bosch num

Firm num

Name

101602-4700

9 400 614 847

1156021260 ISUZU

INJECTION-PUMP ASSEMBLY

6BG1T K 14BF INJECTION PUMP ASSY PE6AD PE

6BG1T K 14BF INJECTION PUMP ASSY PE6AD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.7

Pump speed

r/min

1075

1075

1075

Average injection quantity

mm3/st.

76.8

75.3

78.3

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7+-0.5

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

10

8.7

11.3

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Test data Ex:

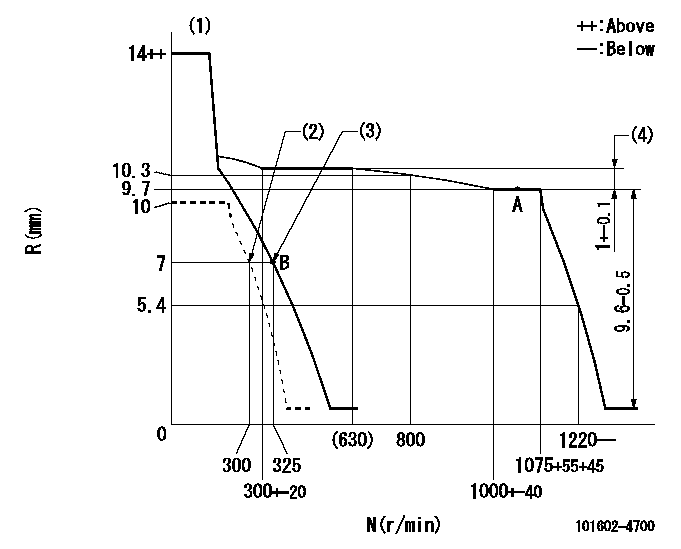

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Set idle sub-spring

(3)Main spring setting

(4)Rack difference between N = N1 and N = N2

----------

K=7 N1=1075r/min N2=500r/min

----------

----------

K=7 N1=1075r/min N2=500r/min

----------

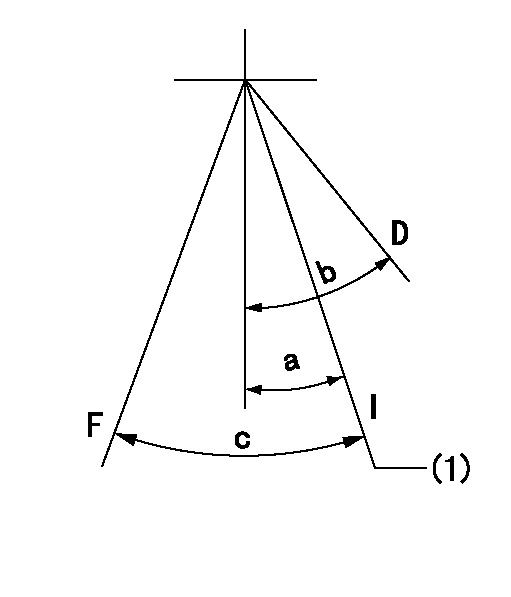

Speed control lever angle

F:Full speed

I:Idle

D:Dead point

(1)Stopper bolt setting

----------

----------

a=22deg+-1deg b=(16deg)+-3deg c=(23deg)+-5deg

----------

----------

a=22deg+-1deg b=(16deg)+-3deg c=(23deg)+-5deg

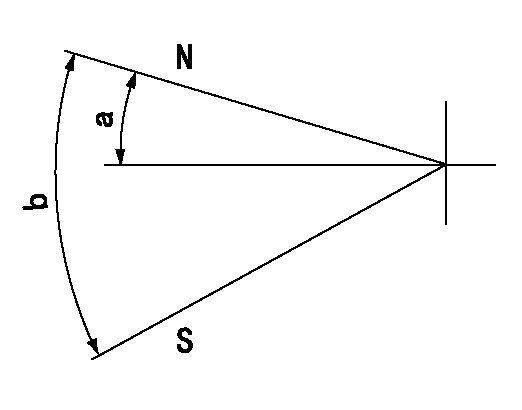

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=12deg+-5deg b=46deg+-5deg

----------

----------

a=12deg+-5deg b=46deg+-5deg

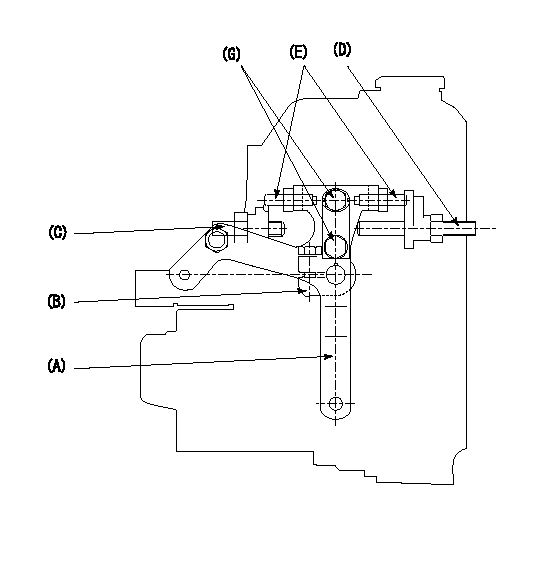

0000001501 LEVER

1. Variable lever adjustment

(1)Fix lever (B) in the idle position using bolts (C) and (D).

(2)Temporarily fix the lever (A) at the dead point and measure the lever angle .

(3)Fix the lever (A) at the idle lever angle position using the bolt (E).

(4)Lock using bolt (G).

(5)After completing idle adjustment, loosen the full side stopper bolt (D).

(6)Move the lever (A) in the full speed direction.

(7)Fix bolt (D) at full speed position.

(8)Finally, measure the lever angle and set the idle stopper bolt (C) stop position.

----------

----------

----------

----------

Timing setting

(1)Pump vertical direction

(2)Position of flywheel's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=13deg

----------

a=(10deg)

----------

aa=13deg

----------

a=(10deg)

Information:

* Select an appropriate cleaning method according to the condition of the cooling system as shown below.

* FUSO DIESEL LONGLIFE COOLANT is flammable. Keep them away from heat and flames.

* If you accidentally splash FUSO DIESEL LONGLIFE COOLANT, FUSO ANTIFREEZE, OR RADIATOR ANTIRUST (RADIPET 9) in your eyes, wash it out immediately with water and seek medical attention.

Air Bleeding of Cooling System

* With the pressure cap removed and the coolant temperature at 90°C, let the engine idle in order to bleed air completely out of the cooling system.* After air bleeding is completed, refill the reservoir tank with coolant as needed.Air/Gas Leakage Test

* Presence of air or exhaust gas in coolant accelerates corrosion of the cooling system components. To prevent this, carry out air/gas leakage tests in accordance with the following procedure.* Remove the pressure cap.

* If the engine is hot, boiling coolant may spurt out from the filler port when the pressure cap is loosened. To avoid being scold, make sure to remove the pressure cap only when the coolant is cold.

* Run the engine until the coolant temperature rises to approximately 90°C. * If air bubbles appear continuously through the filler port, there is air or exhaust gas penetrating into the cooling system.* Presence of air in coolant can be an indication of loose cylinder head bolts, loose water pump mounting bolts, loose hose connections, and/or a damaged hose.* Presence of exhaust gas in coolant can be an indication of a damaged cylinder head gasket and/or cracks in the cylinder head.Inspection of Coolant Leak

* With the engine idling, check the coolant passage (radiator hose, water hose, etc.) for coolant leak.* If any leak is found, check the installation condition of each part and retighten the loose part to the specified torque.If any crack or damage is found on a pipe or hose, replace it to a new one.Coolant Fan, Belt And Water Pump

Removal Sequence1 Cooling fan2 Fan spacer3 Belt4 Water pump pulley5 Water pump6 O-ringX: Non-reusable parts* The water pump cannot be disassembled. It must be replaced if defective. Installation SequenceFollow the removal sequence in reverse.

* The water pump pulley is driven by two belts. Always replace the two belts simultaneously to ensure that both belts have the same tension.* Make sure that there is no oil or grease on the belts. Belts soiled with oil or grease may easily slip, resulting in deteriorated performance of the cooling system.* Keep the O-ring free from engine oil. Engine oil will make the O-ring swell, which may cause leakage.

* After installation, check and adjust the belt tension. (See "GENERAL INSPECTION AND ADJUSTMENT".)Lubricant and/or sealant Water Hose And Pipe

Disassembly Sequence1 Heater return pipe2 O-ring3 Water temperature sensor4 Water outlet pipe5 Gasket*a: Thermostat caseX: Non-reusable parts Assembly SequenceFollow the disassembly sequence in reverse.

* Keep the O-ring free of engine oil. Engine oil will make the O-ring swell, which may cause leakage.

Tightening Torque (Unit: N m {kgf m}) Lubricant and/or sealant Thermostat

Disassembly Sequence1 Thermostat cover2 Thermostat3 Bypass Pipe4 O-ring5 Thermostat

* FUSO DIESEL LONGLIFE COOLANT is flammable. Keep them away from heat and flames.

* If you accidentally splash FUSO DIESEL LONGLIFE COOLANT, FUSO ANTIFREEZE, OR RADIATOR ANTIRUST (RADIPET 9) in your eyes, wash it out immediately with water and seek medical attention.

Air Bleeding of Cooling System

* With the pressure cap removed and the coolant temperature at 90°C, let the engine idle in order to bleed air completely out of the cooling system.* After air bleeding is completed, refill the reservoir tank with coolant as needed.Air/Gas Leakage Test

* Presence of air or exhaust gas in coolant accelerates corrosion of the cooling system components. To prevent this, carry out air/gas leakage tests in accordance with the following procedure.* Remove the pressure cap.

* If the engine is hot, boiling coolant may spurt out from the filler port when the pressure cap is loosened. To avoid being scold, make sure to remove the pressure cap only when the coolant is cold.

* Run the engine until the coolant temperature rises to approximately 90°C. * If air bubbles appear continuously through the filler port, there is air or exhaust gas penetrating into the cooling system.* Presence of air in coolant can be an indication of loose cylinder head bolts, loose water pump mounting bolts, loose hose connections, and/or a damaged hose.* Presence of exhaust gas in coolant can be an indication of a damaged cylinder head gasket and/or cracks in the cylinder head.Inspection of Coolant Leak

* With the engine idling, check the coolant passage (radiator hose, water hose, etc.) for coolant leak.* If any leak is found, check the installation condition of each part and retighten the loose part to the specified torque.If any crack or damage is found on a pipe or hose, replace it to a new one.Coolant Fan, Belt And Water Pump

Removal Sequence1 Cooling fan2 Fan spacer3 Belt4 Water pump pulley5 Water pump6 O-ringX: Non-reusable parts* The water pump cannot be disassembled. It must be replaced if defective. Installation SequenceFollow the removal sequence in reverse.

* The water pump pulley is driven by two belts. Always replace the two belts simultaneously to ensure that both belts have the same tension.* Make sure that there is no oil or grease on the belts. Belts soiled with oil or grease may easily slip, resulting in deteriorated performance of the cooling system.* Keep the O-ring free from engine oil. Engine oil will make the O-ring swell, which may cause leakage.

* After installation, check and adjust the belt tension. (See "GENERAL INSPECTION AND ADJUSTMENT".)Lubricant and/or sealant Water Hose And Pipe

Disassembly Sequence1 Heater return pipe2 O-ring3 Water temperature sensor4 Water outlet pipe5 Gasket*a: Thermostat caseX: Non-reusable parts Assembly SequenceFollow the disassembly sequence in reverse.

* Keep the O-ring free of engine oil. Engine oil will make the O-ring swell, which may cause leakage.

Tightening Torque (Unit: N m {kgf m}) Lubricant and/or sealant Thermostat

Disassembly Sequence1 Thermostat cover2 Thermostat3 Bypass Pipe4 O-ring5 Thermostat

Have questions with 101602-4700?

Group cross 101602-4700 ZEXEL

Isuzu

101602-4700

9 400 614 847

1156021260

INJECTION-PUMP ASSEMBLY

6BG1T

6BG1T