Information injection-pump assembly

ZEXEL

101602-3840

1016023840

Rating:

Cross reference number

ZEXEL

101602-3840

1016023840

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4

3.95

4.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

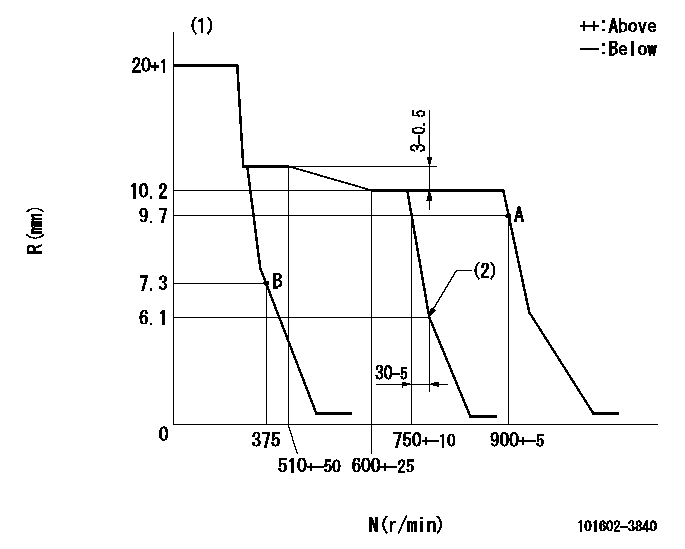

Injection quantity adjustment

Adjusting point

A

Rack position

9.7

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

89.5

88.5

90.5

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.3+-0.5

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

13

11.8

14.2

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Idle sub spring setting: L1.

----------

K=16 L1=6.1-0.5mm

----------

----------

K=16 L1=6.1-0.5mm

----------

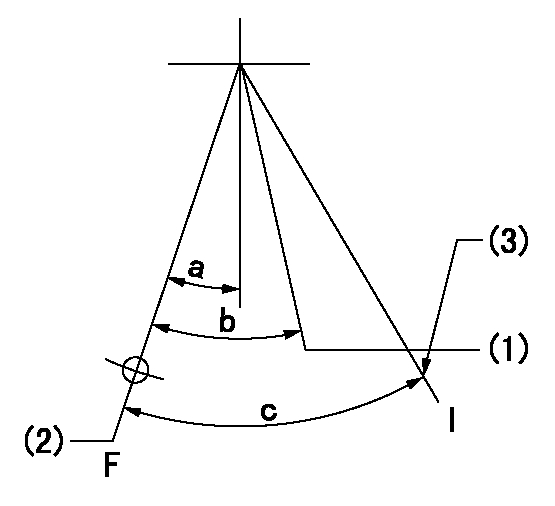

Speed control lever angle

F:Full speed

I:Idle

(1)Pump speed = aa

(2)Speed = bb (at shipping)

(3)Stopper bolt setting

----------

aa=750r/min bb=900r/min

----------

a=5deg+-5deg b=6deg+-5deg c=25deg+-5deg

----------

aa=750r/min bb=900r/min

----------

a=5deg+-5deg b=6deg+-5deg c=25deg+-5deg

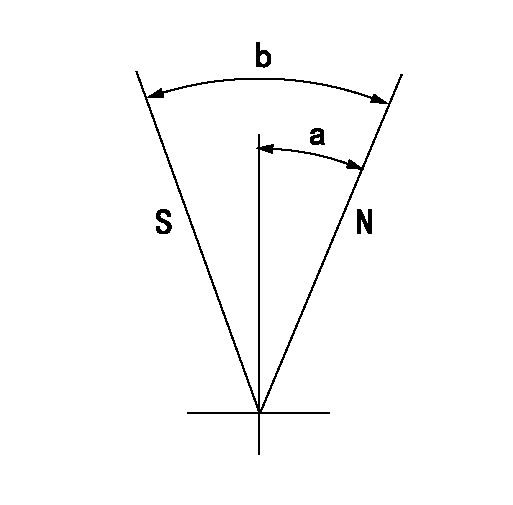

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=27deg+-5deg b=53deg+-5deg

----------

----------

a=27deg+-5deg b=53deg+-5deg

Information:

Illustration 9 g06286243

Typical example

Illustration 9 shows the governor plate displaying high wear at the sleeve contact points.

Illustration 10 g06286261

Typical example

Illustration 8 shows the thrust sleeve displaying an excessive wear groove.

Illustration 11 g06286627

Typical example

Illustration 12 g06286629

Typical example

Illustration 11 and Illustration 11 show the weight thrust fingers badly worn.

Illustration 13 g06286630

Typical example

Illustration 13 shows pivot heels showing excessive wear.Fuel Quality

Illustration 14 g06286604

Typical example

Illustration 14 shows that nitrile rubber seals have cracked causing fuel leakage. The cracks in the seals are attributed to fuel attacking the rubber. Ensure that there is no particle contamination in the fuel injection pump.Unmodified Vegetable Oil or Poor Quality FAME

Illustration 15 g06286612

Typical example

Stuck metering valve causing engine overspeed. Top cover of fuel injection pump removed. Black sticky material adhering to all non-alloy surfaces, this is due to the use of unmodified vegetable oil or poor quality FAME. Refer to Illustration 15.High Water Content in Fuel

Illustration 16 g06286613

Typical example

Illustration 17 g06286615

Typical example

Illustration 16 and Illustration 17 show corrosion on component surfaces, due to high water content in fuel.Characteristics Associated with Poor Quality Fuel and Potential Issue

Table 1

Fuel Characteristics Effect Issue

FAMEs in general Causes some elastomers to soften, swell, harden, and crack. Fuel leakage.

Free methanol in FAME Corrodes aluminum and zinc. Low flash point. Corrosion on fuel injection equipment.

FAME process chemicals Potassium and sodium compound. Solid particles. Blocked nozzles.

Dissolved water in FAME Reversion of FAME to a fatty acid. Fuel filter plugging.

Free water in FAME Corrosion. Sustains bacteria. Corrosion on fuel injection equipment. Sludging.

Free glycerine, mono, and

di-glycerines in FAME Corrodes non-ferrous metals.

Sediments on moving parts and lacquering. Fuel filter clogging.

Fuel injector clogging.

Free fatty acid Corrosion of Zinc plating.

Slats of organic acids.

Organic compound formed. Corrosion on fuel injection equipment.

Fuel filter plugging.

Sediment on components

High viscosity at low temperature Generates excessive localized heat.

Higher stressed components. Fuel injection pump seizures.

Early life issues.

Poor nozzle spray.

Corrosive acids Corrodes all metallic parts. Corrosion on fuel injection equipment.

High molecular organic acids Corrosion of Zinc plating.

Slats of organic acids.

Organic compound formed. Corrosion on fuel injection equipment.

Fuel filter plugging.

Sediment on components

Polymerization products Deposits in fuel mixes Fuel filter plugging. Lacquering formation in hot areas. Recommended Procedures

Prime the fuel system to remove any air. Refer to Operation and Maintenance Manual, Fuel System - Prime for the correct procedure.Check the pressure of the fuel system. Refer to Systems Operation, Testing and Adjusting, Fuel System Pressure - Test for the correct procedure.Check the operation of the fuel injection nozzles. Refer to Systems Operation, Testing and Adjusting, Fuel Injection Nozzle - Test for the correct procedure.To inspect the fuel injection pump, refer to Special Instruction, REHS3767, Inspection of Fuel Injection Pumps on 3054C, C3.3, C4.4 (Mechanical), and C7.1 (Mechanical) Engines for the correct procedure.