Information injection-pump assembly

ZEXEL

101602-3350

1016023350

KOMATSU

6137711510

6137711510

Rating:

Cross reference number

ZEXEL

101602-3350

1016023350

KOMATSU

6137711510

6137711510

Zexel num

Bosch num

Firm num

Name

101602-3350

6137711510 KOMATSU

INJECTION-PUMP ASSEMBLY

SL6D105 * K

SL6D105 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.5

3.45

3.55

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.4

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

51.5

50.5

52.5

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

8+-0.5

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

10.5

9

12

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

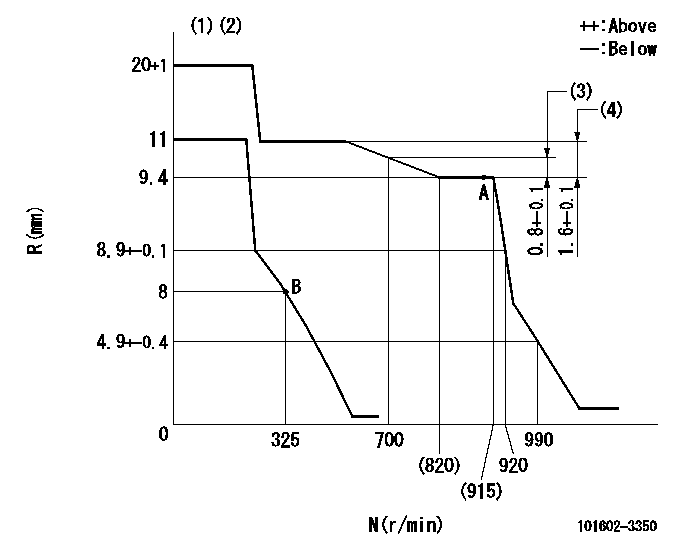

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Rack difference from N = N1

(4)Rack difference between N = N2 and N = N3

----------

K=15 N1=900r/min N2=900r/min N3=450r/min

----------

----------

K=15 N1=900r/min N2=900r/min N3=450r/min

----------

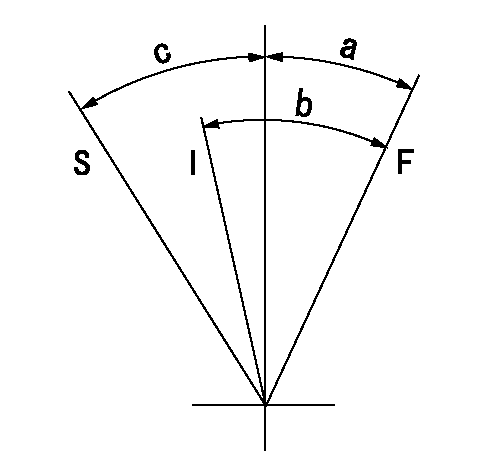

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=6deg+-5deg b=30deg+-5deg c=32deg+-3deg

----------

----------

a=6deg+-5deg b=30deg+-5deg c=32deg+-3deg

0000001501 LEVER

(F) P/N: Part number of the shim

L1:Thickness (mm)

1. Adjustment of the control lever

(1)Perform idling with the control lever (A) contacting the pushrod (B). At this time, confirm that the spring (C) is not compressed by control lever (A)'s operating torque.

(2)To set the stop position, compress spring (C) using the control lever (A) and adjust the rack so that it contacts the guide screw (D) at position L2. Then, set and fix using the lock nut (E). Adjust the rack position L2 at this time using the shim (F).

(3)Confirm that the control lever (A) returns to the idling position when pulled in the stop direction and then released.

----------

L2=0.2~2mm

----------

----------

L2=0.2~2mm

----------

Information:

Table 3

Injector Resistance Measurement

Step Instruction Completed

(Yes/No) Results

Comments Units

1 Turn the keyswitch to the OFF position. Allow 2 minutes to elapse before proceeding.

2 Disconnect the DEF injector from the applicable harness.

3 Inspect the connector for damage or debris (if damaged take photo)

4 Measure the temperature of the injector (aluminum body) C

5 Connect two 398-4987 connectors to the DEF injector. The connectors must be used to prevent damage to the DEF injector connector.

6 Measure the resistance of the DEF injector. Ohms

Table 4

Dosing Accuracy Test

Step Instruction Completed

(Yes/No) Results

Comments Units

1 Follow the Testing and Adjusting, Aftertreatment SCR System Dosing - Test.

2 Remove the injector from the DPF outlet.

3 Take a photograph of the DEF injector mount on the DPF outlet and the tip of the DEF injector.

4 Install the injector on the beaker.

5 Run the DEF System Dosing Accuracy test through Cat ET.

6 Use the breaker to measure the amount of fluid from the dosing test. ml

7 Repeat the test to verify consistency. ml

8 Install the injector back onto the DPF outlet.

Illustration 2 g06068068

DEF Injector Resistance Measurement

Illustration 3 g06067706

Injector Mount on DPF (Outlet Sample Picture)

Illustration 4 g06067753

DEF Injector Tip (Sample Picture)

When troubleshooting requests the DEF quality check, DEF injector resistance measurement or Dosing Accuracy Test, please document results in the Tables shown above.

After completing troubleshooting and performing the Aftertreatment System Functional Test, download a new Product Status Report with all ECM's.

Table 5

Injector Failure Report

Step Instruction Completed

(Yes/No) Results

Comments Units

1 Download "Product Status Report" (PSR) from the engine ECM and send to the email address in the instructions.

2 Download "Warranty Report" (WR) from the engine ECM and send to the email address in the instructions.

3 Take a picture of the injector part number / serial number.

4 Follow the correct TSG based on Table 1 and complete tables 2 through 4 when they apply.

5 Perform an "Aftertreatment System Functional Test".

6 Download "Product Status Report" (PSR) from the engine ECM and send to the email address in the instructions.

7 Submit "TIB Check List", "Product Status Reports", DEF injector deposits photographs, CEM deposit photographs, and DEF injector part number and serial number photograph to the email address in the instructions.

Fill out the Injector Failure Report and send all information including product status reports, warranty reports, DEF injector and mount photos, DEF injector part number and serial number and test results to the email address provided above.

Have questions with 101602-3350?

Group cross 101602-3350 ZEXEL

Komatsu

101602-3350

6137711510

INJECTION-PUMP ASSEMBLY

SL6D105

SL6D105