Information injection-pump assembly

BOSCH

9 400 614 815

9400614815

ZEXEL

101602-3170

1016023170

KOMATSU

6136711512

6136711512

Rating:

Service parts 101602-3170 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

6130-11-3104

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 614 815

9400614815

ZEXEL

101602-3170

1016023170

KOMATSU

6136711512

6136711512

Zexel num

Bosch num

Firm num

Name

101602-3170

9 400 614 815

6136711512 KOMATSU

INJECTION-PUMP ASSEMBLY

6D105 K 14BE INJECTION PUMP ASSY PE6A PE

6D105 K 14BE INJECTION PUMP ASSY PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.5

3.45

3.55

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

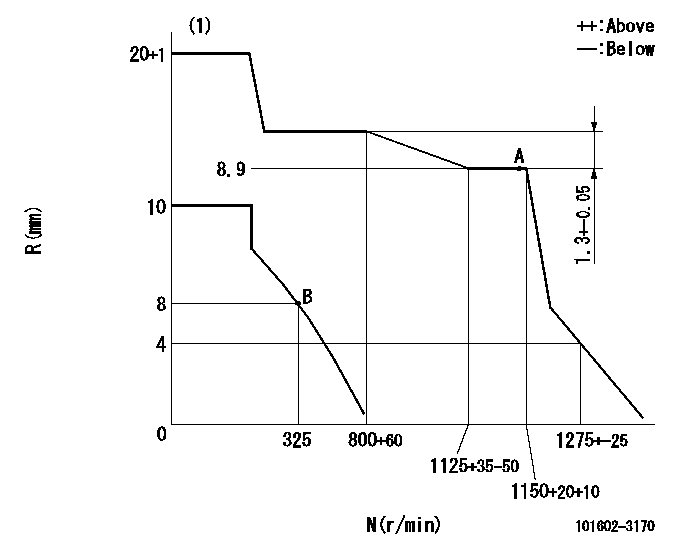

Injection quantity adjustment

Adjusting point

A

Rack position

8.9

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

48.5

47.5

49.5

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

8+-0.5

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

12.5

11

14

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

----------

K=10

----------

----------

K=10

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=20deg+-5deg b=8deg+-5deg

----------

----------

a=20deg+-5deg b=8deg+-5deg

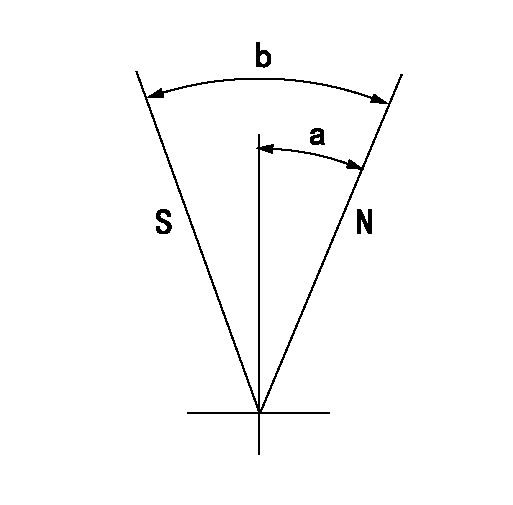

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=(27deg) b=(53deg)

----------

----------

a=(27deg) b=(53deg)

Information:

Observe the safe working load limits of all lifting and blocking devices and keep a safe distance from suspended/blocked loads. Personnel may be seriously injured or killed by falling loads.

Problem

There have been isolated instances where the Diesel Exhaust Fluid (DEF) pressure sensor within the DEF pump breaks and DEF leaks into the DEF pump. DEF wicks up the wiring between the DEF pump and the interface connector. The DEF then shorts across the pins of the connector leading to the issue.Solution

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Using an electronic service tool, generate a Product Status Report (PSR) with the engine running histograms and abnormal shutdown history included.

Check to see if the DEF system has been contaminated. Examples of contaminants are fuels, oils, coolant, and wind shield washer fluid.

DEF Injector

Remove electrical connector and examine it for the presence of DEF.

Illustration 1 g06386447

Typical example of a DEF injector

(1) Location of the serial number

(2) DEF injector

(3) DEF injector electrical connectorNote: Do not remove DEF injector from Clean Emissions Module (CEM).

Illustration 2 g06386460

Typical example DEF injector electrical connector

Examine the OEM harness connection for the presence of DEF in the connector.

31-Pin Connector

Illustration 3 g06386503

Typical example of a 31-pin connector

Confirm that the 31-pin connector is securely tightened.

Illustration 4 g06386512

Typical example of a 31-pin connector with blanking caps

(4) Blanking caps

Ensure that blanking caps (4) are in place on the unused pins on both sides 31-pin connector.

Illustration 5 g06388958

Typical example of a 31-pin connector O-Ring location

Disconnect 31-pin connector and ensure that the O-Ring is in the correct position in the machine side of the connection. Position (Y) shows where the red O-Ring seal is located.

Check for fluid contamination in the 31-pin connector. If contaminant is present, determine what the contaminant is. Check for DEF, which leaves white residue marks or the PH level (9 to 9.5).Check for diesel using HC strips. Check for water (PH 7).

Check for signs of overheating or corrosion.

Machine Fuse

Inspect DEF fuse condition and the fuse rating.

DEF Injector

Using a suitable multimeter, measure the electrical resistance on DEF injector connector pin 1 to pin 2. If the measured resistance is less than 6 Ohms or more than 8 Ohms, a fault in the injector is detected.

Check for signs of the presence of DEF within the machine electrical wires connected to the DEF injector.

Check the history of the machine for previous DEF injector issues.

Use the electronic service tool to generate a PSR and obtain an abnormal shutdown, engine running histograms, and application history.

Check for logged 3361-5 or 3821-5 "Aftertreatment #1 DEF Dosing Unit: Current Below Normal" diagnostic codes.

Using a suitable multimeter, measure the resistance between the following points:

31-pin connector pin 11 and pin 2 DEF injector connector.

31-pin connector pin 12 and pin 1 DEF injector connector.

If the measured resistance is greater than 2 Ohms. There is an open

Have questions with 101602-3170?

Group cross 101602-3170 ZEXEL

Komatsu

101602-3170

9 400 614 815

6136711512

INJECTION-PUMP ASSEMBLY

6D105

6D105