Information injection-pump assembly

BOSCH

9 400 614 810

9400614810

ZEXEL

101602-3120

1016023120

KOMATSU

6137711401

6137711401

Rating:

Service parts 101602-3120 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

6137-12-3100

12.

Open Pre:MPa(Kqf/cm2)

22.1{225}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 614 810

9400614810

ZEXEL

101602-3120

1016023120

KOMATSU

6137711401

6137711401

Zexel num

Bosch num

Firm num

Name

101602-3120

9 400 614 810

6137711401 KOMATSU

INJECTION-PUMP ASSEMBLY

S6D105 K 14BE INJECTION PUMP ASSY PE6A PE

S6D105 K 14BE INJECTION PUMP ASSY PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.3

3.25

3.35

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

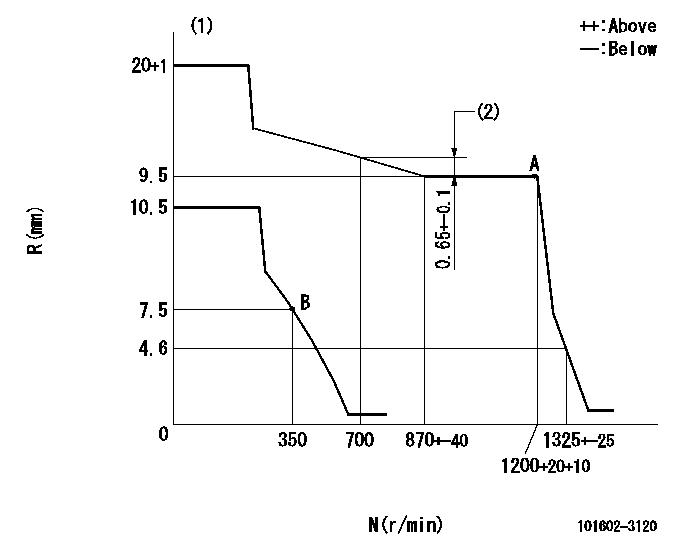

Injection quantity adjustment

Adjusting point

A

Rack position

9.5

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

64

63

65

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.5+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

9

7.2

10.8

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Rack difference between N = N1 and N = N2

----------

K=10 N1=1200r/min N2=700r/min

----------

----------

K=10 N1=1200r/min N2=700r/min

----------

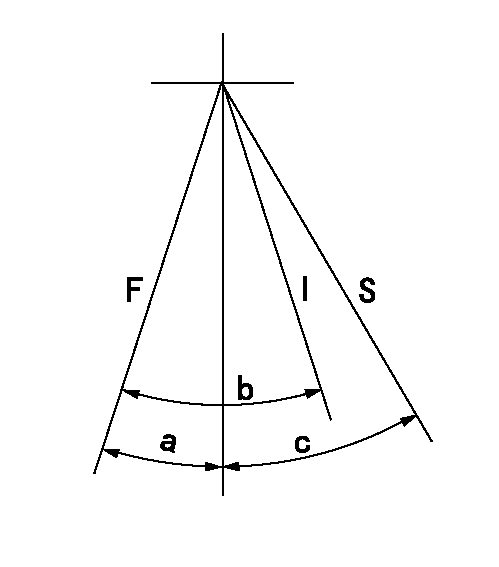

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=10deg+-5deg b=22deg+-5deg c=32deg+-3deg

----------

----------

a=10deg+-5deg b=22deg+-5deg c=32deg+-3deg

Information:

Caterpillar does not warrant the quality or performance of non-Cat fluids.

How Fuel and Oil Affects Cat DPF Performance

For the maximum performance in filtration and regeneration efficiency, operating the Cat DPF with ultra-low sulfur diesel fuel (ULSD-S15), of less than 15 ppm sulfur by weight is recommended. ULSD fuel must meet the S-15 fuels designation in the latest edition of ASTM D975 and/or conform to Cat Fuel Specification. Using ULSD, regeneration for engines certified to Tier II and lower regulations will occur when the duty cycle is above 300° C (572° F) for at least 30 percent of the operating time. For Tier III and greater engines, consult Cat for operating requirements.Operating the Cat DPF on diesel engines using fuel with sulfur content greater than 50 ppm will increase the regeneration temperature requirements significantly of approximately 50-90°C (90-135°F). If the exhaust temperature meets these requirements, continuous regeneration still can take place. If the normal operation of the Cat DPF is on ULSD but the engine is accidentally fueled with high sulfur fuel the regeneration temperature requirements will increase accordingly. With added sulfur, the normal duty cycle of the engine may cause the filter to plug with particulate matter PM. This condition will cause the backpressure to increase beyond the engine manufacturer limits. This condition could damage the filter and/or the engine.When the fuel sulfur level is once again below 50 ppm, ULSD operating conditions will return. High sulfur fuel will not damage the catalyst coating or the ceramic filter. High sulfur fuel will change the regeneration requirements as stated above.Biodiesel fuel may be used up to the B20 blend level (20 percent biodiesel and 80 percent appropriate ULSD fuel) IF the final B20 blend conforms to ASTM D7467 and API gravity 30-45. The neat biodiesel blend stock should conform to ASTM 6751. Cat diesel engine oils (CAT DEO) have been developed and tested in order to provide the full performance and service life that has been designed and built into Cat engines. Catt oils are currently used to fill Cat Diesel Engines at the factory. These oils are offered by Cat dealers for continued use when the engine oil is changed. Consult your Cat dealer for more information on these oils.Cat DEO-ULSTM(Ultra Low Sulfur) Oil exceeds the performance requirements of API category CJ-4 oil and is recommended due to a low ash specification. Engine oil that meets or exceeds the specifications in the Cat ECF-3 or API CJ4 categories may be used in these applications. Oil burned during the combustion process accounts for almost all of the DPF ash accumulation (because of oil additives). The use of recommended low ash oil results in lower ash accumulation in the filter. Failure to use the recommended grade of oil may results in more frequent ash removal service intervals.Note: Cat DEO and Cat DEO-ULS multigrade oils are the preferred oils for use in this Cat Diesel Engine.

Table 1

Commercial Lubricants Cat Lubricants Viscosity Grade

Diesel Engine Oil-Ultra Low Sulfur (API

Have questions with 101602-3120?

Group cross 101602-3120 ZEXEL

Komatsu

101602-3120

9 400 614 810

6137711401

INJECTION-PUMP ASSEMBLY

S6D105

S6D105