Information injection-pump assembly

BOSCH

9 400 614 805

9400614805

ZEXEL

101602-3040

1016023040

KOMATSU

6136711101

6136711101

Rating:

Service parts 101602-3040 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

6137-12-3100

12.

Open Pre:MPa(Kqf/cm2)

22.1{225}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 614 805

9400614805

ZEXEL

101602-3040

1016023040

KOMATSU

6136711101

6136711101

Zexel num

Bosch num

Firm num

Name

9 400 614 805

6136711101 KOMATSU

INJECTION-PUMP ASSEMBLY

6D105 K 14BE INJECTION PUMP ASSY PE6A PE

6D105 K 14BE INJECTION PUMP ASSY PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.5

3.45

3.55

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

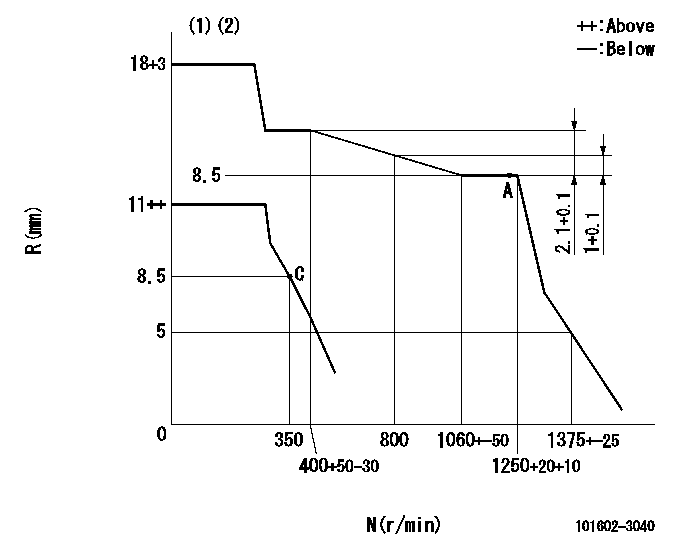

Injection quantity adjustment

Adjusting point

A

Rack position

8.5

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

41.5

40.5

42.5

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

8.5+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

11

9

13

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Full and idle rack positions are the same.

----------

K=7

----------

----------

K=7

----------

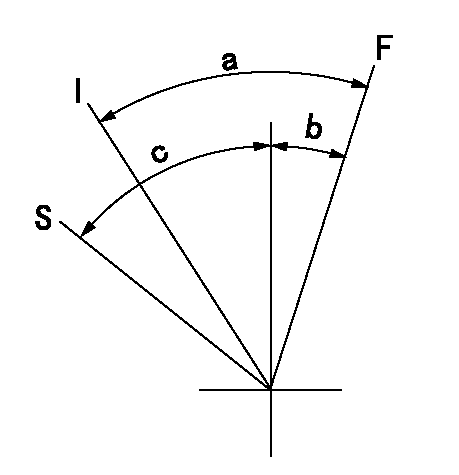

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=21deg+-5deg b=6deg+-5deg c=32deg+-3deg

----------

----------

a=21deg+-5deg b=6deg+-5deg c=32deg+-3deg

0000001501 LEVER

(F) P/N: Part number of the shim

L1:Thickness (mm)

1. Adjustment of the control lever

(1)Perform idling with the control lever (A) contacting the pushrod (B). At this time, confirm that the spring (C) is not compressed by control lever (A)'s operating torque.

(2)To set the stop position, compress spring (C) using the control lever (A) and adjust the rack so that it contacts the guide screw (D) at position L2. Then, set and fix using the lock nut (E). Adjust the rack position L2 at this time using the shim (F).

(3)Confirm that the control lever (A) returns to the idling position when pulled in the stop direction and then released.

----------

L2=0.2~2mm

----------

----------

L2=0.2~2mm

----------

Information:

Cleaning the DPF

Because the sections of the DPF are replaceable, a small stock of filter sections can be maintained. Filter sections from a small on-hand stock can be used to replace filters in service at the next scheduled cleaning. The removed filters can be cleaned and returned for installation in the next vehicle. This process of maintaining a stock of filter sections can significantly reduce the amount of down time that will occur.Note: Check State and Local air pollution regulations pertaining to record keeping of serviced filters. Some governmental entities may require filter tracking. Note: Perform a back pressure test prior to cleaning the DPF and record the results. After cleaning the DPF, run the engine at high idle for 5 to 15 minutes to bring the engine and exhaust system to operating temperature. Perform another back pressure test and record the results on the DPF cleaning records form.

Weigh and record the filter unit prior to baking.

By baking the filter under a controlled procedure, the remaining soot on the DPF will burn off and leave a smaller quantity of ash. Failure to observe this procedure can result to damage or cracking to the DPF substrate. A commercial programmable oven is required for this procedure. Careful adherence to this procedure is imperative. Deviation from this procedure may lead to thermal shock and cracking of the DPF substrate or melting at high temperatures.

Place filter into a programmable commercial oven designed for this purpose. Center the filter as much as possible on a rack with 2 inches of spacing below and above for best results.

Program the oven as follows:

Ramp oven temperature to 200° C (392° F)

Hold oven temperature at 200° C (392° F)

Ramp oven temperature to 450° C (842° F)

Hold oven temperature at 450° C (842° F)

Cool down to ambient temperature at natural rate within the oven with the doors closed. Do not use fans.

Place filter in cleaning machine and clean as per machine instructions.

Replace the filter in the oven. Ramp to 650° C (1202° F) in 60 minutes.

Hold oven temperature at 650° C (1202° F) for 240 minutes.

Cool to ambient temperature at a natural rate. Do not use fans.Note: Allow the filter to cool in the oven with the door closed until the filter can be handled with bare hands.Cleaning Procedure

Ash and soot should be removed from the DPF utilizing the Cat 319-2189 Diesel Particulate Filter Cleaner Gp. Using the cleaner without following baking procedure, results in lower efficiency cleaning and will reduce the life of the HEPA filters in the machine. The tool uses pulsed air to flush the ash and soot.Note: Other cleaning methods can release significant quantities of airborne ash and soot. Airborne ash and soot should not be inhaled and may be regulated as a hazardous substance by local regulations.Cleaned Filter Specification

The following steps determine if the DPF was properly cleaned:Note: This specification applies to filters that were cleaned of ash only. This specification is only valid subsequent to the recommend

Because the sections of the DPF are replaceable, a small stock of filter sections can be maintained. Filter sections from a small on-hand stock can be used to replace filters in service at the next scheduled cleaning. The removed filters can be cleaned and returned for installation in the next vehicle. This process of maintaining a stock of filter sections can significantly reduce the amount of down time that will occur.Note: Check State and Local air pollution regulations pertaining to record keeping of serviced filters. Some governmental entities may require filter tracking. Note: Perform a back pressure test prior to cleaning the DPF and record the results. After cleaning the DPF, run the engine at high idle for 5 to 15 minutes to bring the engine and exhaust system to operating temperature. Perform another back pressure test and record the results on the DPF cleaning records form.

Weigh and record the filter unit prior to baking.

By baking the filter under a controlled procedure, the remaining soot on the DPF will burn off and leave a smaller quantity of ash. Failure to observe this procedure can result to damage or cracking to the DPF substrate. A commercial programmable oven is required for this procedure. Careful adherence to this procedure is imperative. Deviation from this procedure may lead to thermal shock and cracking of the DPF substrate or melting at high temperatures.

Place filter into a programmable commercial oven designed for this purpose. Center the filter as much as possible on a rack with 2 inches of spacing below and above for best results.

Program the oven as follows:

Ramp oven temperature to 200° C (392° F)

Hold oven temperature at 200° C (392° F)

Ramp oven temperature to 450° C (842° F)

Hold oven temperature at 450° C (842° F)

Cool down to ambient temperature at natural rate within the oven with the doors closed. Do not use fans.

Place filter in cleaning machine and clean as per machine instructions.

Replace the filter in the oven. Ramp to 650° C (1202° F) in 60 minutes.

Hold oven temperature at 650° C (1202° F) for 240 minutes.

Cool to ambient temperature at a natural rate. Do not use fans.Note: Allow the filter to cool in the oven with the door closed until the filter can be handled with bare hands.Cleaning Procedure

Ash and soot should be removed from the DPF utilizing the Cat 319-2189 Diesel Particulate Filter Cleaner Gp. Using the cleaner without following baking procedure, results in lower efficiency cleaning and will reduce the life of the HEPA filters in the machine. The tool uses pulsed air to flush the ash and soot.Note: Other cleaning methods can release significant quantities of airborne ash and soot. Airborne ash and soot should not be inhaled and may be regulated as a hazardous substance by local regulations.Cleaned Filter Specification

The following steps determine if the DPF was properly cleaned:Note: This specification applies to filters that were cleaned of ash only. This specification is only valid subsequent to the recommend