Information injection-pump assembly

BOSCH

F 019 Z10 978

f019z10978

ZEXEL

101602-2943

1016022943

HINO

220205233B

220205233b

Rating:

Include in #1:

101482-4130

as _

Cross reference number

BOSCH

F 019 Z10 978

f019z10978

ZEXEL

101602-2943

1016022943

HINO

220205233B

220205233b

Zexel num

Bosch num

Firm num

Name

101602-2943

F 019 Z10 978

220205233B HINO

INJECTION-PUMP ASSEMBLY

J08C-TN K

J08C-TN K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131425-0620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.8

3.77

3.83

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

8.8

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

87

85

89

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

42.7

42.7

Boost pressure

mmHg

320

320

Injection quantity adjustment_02

Adjusting point

C

Rack position

6.3+-0.5

Pump speed

r/min

365

365

365

Average injection quantity

mm3/st.

8.5

7.5

9.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

E

Rack position

9++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

105

105

115

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

800

800

800

Rack position

R1-1.2

Boost pressure

kPa

4.7

3.4

6

Boost pressure

mmHg

35

25

45

Boost compensator adjustment_02

Pump speed

r/min

800

800

800

Rack position

R1(8.8)

Boost pressure

kPa

29.3

22.6

36

Boost pressure

mmHg

220

170

270

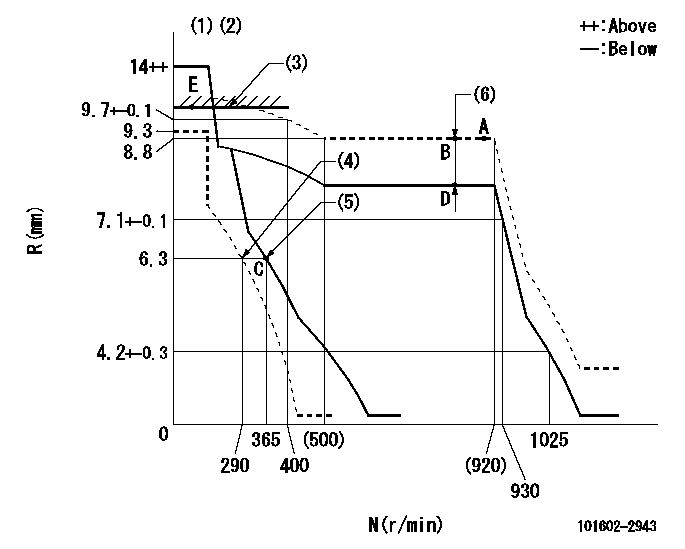

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

(6)Boost compensator stroke: BCL

----------

K=8 BCL=1.2+-0.1mm

----------

----------

K=8 BCL=1.2+-0.1mm

----------

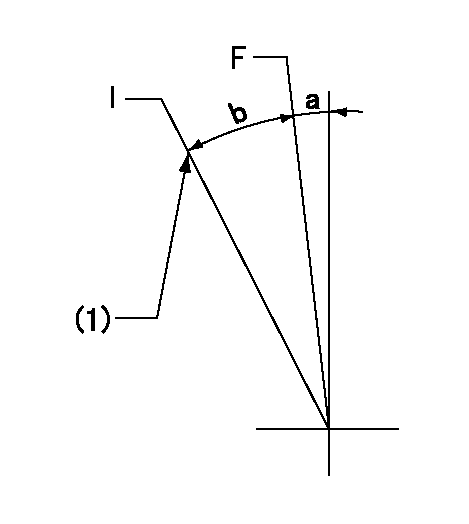

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=3deg+-5deg b=16deg+-5deg

----------

----------

a=3deg+-5deg b=16deg+-5deg

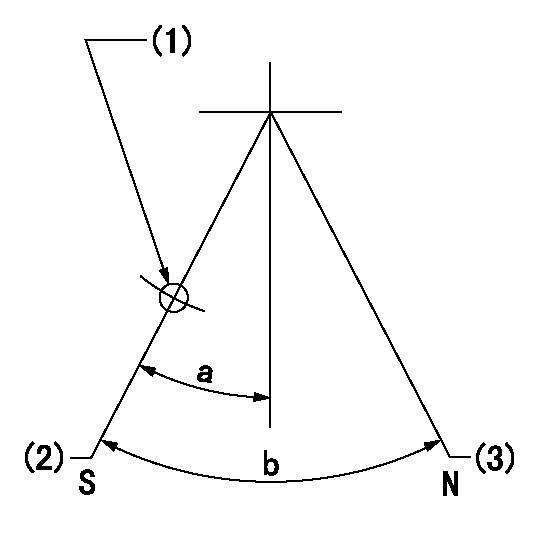

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

(2)Rack position bb, pump speed cc (seal at delivery)

(3)Normal

----------

aa=25mm bb=2-0.5mm cc=0r/min

----------

a=19deg+-5deg b=(53deg)

----------

aa=25mm bb=2-0.5mm cc=0r/min

----------

a=19deg+-5deg b=(53deg)

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(20deg)

----------

----------

a=(20deg)

Information:

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

To improve the reliability and performance of its products, Cat Reman has replaced the entire product line of HI315B Injectors with a version that includes a pre-screen that will capture a portion of the debris trapped in the fuel system during service. The pre-screen will not change the fit, form, or function of the injectors. If a Reman injector order has been filled with new injectors, the new injectors will not have the screen. Injectors both with and without the pre-screen can be used interchangeably.

Illustration 1 g06334704

Table 1

H1315B Injectors

New Part Number Reman Part Number

387-9426 20R-8071

387-9427 20R-8066

387-9428 20R-8059

387-9429 20R-8058

387-9430 20R-8057

387-9431 20R-8069

387-9432 20R-8065

387-9433 20R-8064

387-9434 20R-8063

387-9436 20R-8068

387-9437 20R-8062

387-9438 20R-8060

387-9439 20R-8061

387-9440 20R-8070

387-9441 20R-8067

Have questions with 101602-2943?

Group cross 101602-2943 ZEXEL

Hino

Hino

Hino

Hino

101602-2943

F 019 Z10 978

220205233B

INJECTION-PUMP ASSEMBLY

J08C-TN

J08C-TN