Information injection-pump assembly

ZEXEL

101602-2921

1016022921

Rating:

Cross reference number

ZEXEL

101602-2921

1016022921

Zexel num

Bosch num

Firm num

Name

101602-2921

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.8

4.77

4.83

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

9.4

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

92.5

91

94

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

6.9+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

10.5

9.5

11.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

135

135

145

Fixing the lever

*

Rack limit

*

Test data Ex:

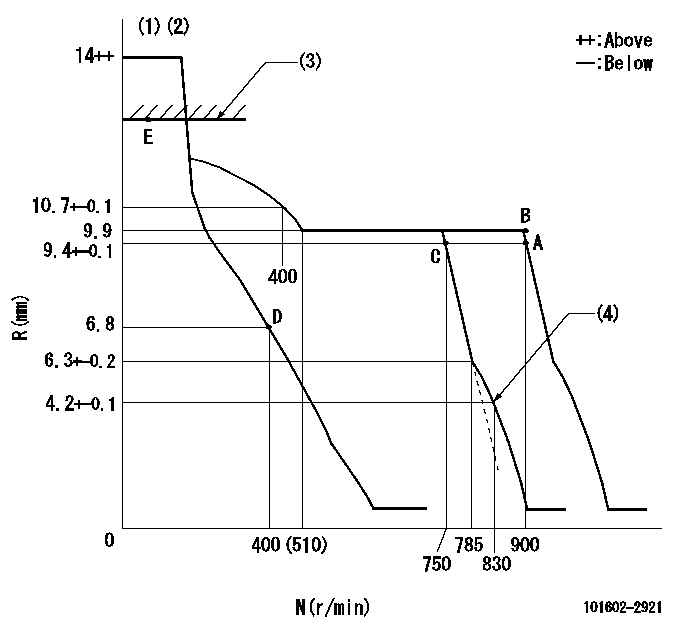

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

----------

K=9

----------

----------

K=9

----------

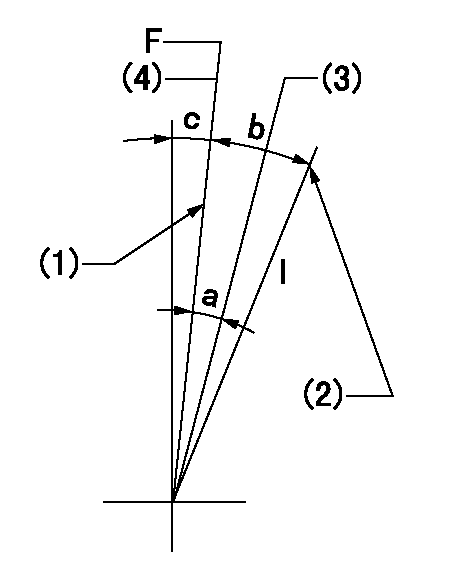

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)Stopper bolt setting

(3)Set the pump speed at aa

(4)Set the pump speed at bb (at delivery)

----------

aa=750r/min bb=900r/min

----------

a=6deg+-5deg b=19deg+-5deg c=0deg+-5deg

----------

aa=750r/min bb=900r/min

----------

a=6deg+-5deg b=19deg+-5deg c=0deg+-5deg

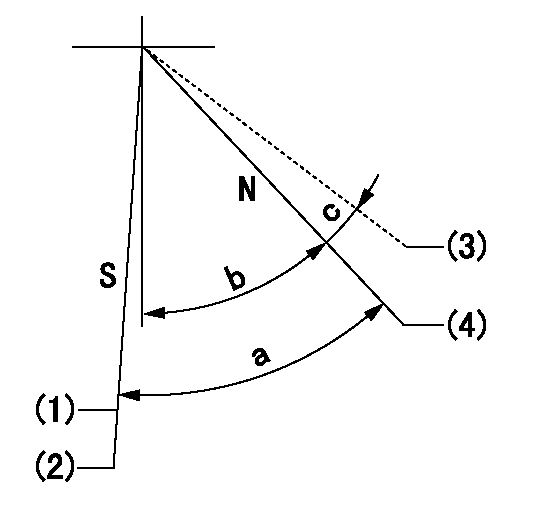

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal stop

(2)Rack position aa or less, pump speed bb

(3)Contacts normal side pin

(4)Clearance from the pin on the normal side: cc

----------

aa=6.3mm bb=0r/min cc=2.5+-0.5mm

----------

a=53deg+-5deg b=51deg+-5deg c=(6deg)

----------

aa=6.3mm bb=0r/min cc=2.5+-0.5mm

----------

a=53deg+-5deg b=51deg+-5deg c=(6deg)

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

There have been instances of the following diagnostic codes becoming active:

Table 1

J1939 Code CDL Code Code Description

1184-3 3782-3 Engine Turbocharger #1 Turbine Outlet Temperature : Voltage Above Normal

1184-4 3782-4 Engine Turbocharger #1 Turbine Outlet Temperature : Voltage Below Normal

3242-3 2452-3 DPF #1 Intake Temperature Sensor : Voltage Above Normal

3242-4 2452-4 DPF #1 Intake Temperature Sensor : Voltage Below Normal

4360-3 3105-3 Aftertreatment #1 SCR Catalyst Intake Gas Temperature Sensor : Voltage Above Normal

4360-4 3105-4 Aftertreatment #1 SCR Catalyst Intake Gas Temperature Sensor : Voltage Below Normal One root cause of the diagnostic codes has been identified as electrical noise overwriting data on the memory chip of the DPF/SCR intake temperature sensor. Improved sensor firmware has resolved this issue.A fault could not be found with some of the returned parts. A new troubleshooting procedure has been released. Refer to Troubleshooting, Sensor Signal (PWM) - Test.

Have questions with 101602-2921?

Group cross 101602-2921 ZEXEL

Hino

Hino

Hino

101602-2921

INJECTION-PUMP ASSEMBLY