Information injection-pump assembly

ZEXEL

101602-2910

1016022910

Rating:

Service parts 101602-2910 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-2142A

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Cross reference number

ZEXEL

101602-2910

1016022910

Zexel num

Bosch num

Firm num

Name

101602-2910

INJECTION-PUMP ASSEMBLY

14BF PE6AD PE

14BF PE6AD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.45

3.42

3.48

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

11

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

69

67

71

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

7.5+-0.5

Pump speed

r/min

450

450

450

Average injection quantity

mm3/st.

9

7.5

10.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

75

75

85

Fixing the lever

*

Rack limit

*

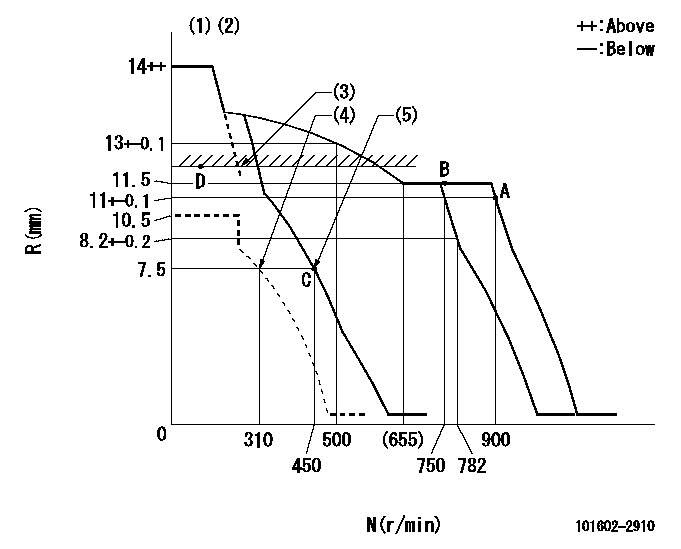

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

----------

K=6

----------

----------

K=6

----------

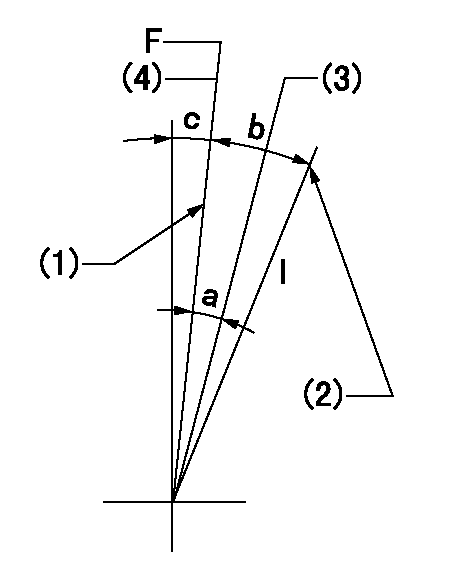

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)Stopper bolt setting

(3)When pump speed set at aa

(4)Set the pump speed at bb.

----------

aa=750r/min bb=900r/min

----------

a=5deg+-5deg b=18deg+-5deg c=2deg+-5deg

----------

aa=750r/min bb=900r/min

----------

a=5deg+-5deg b=18deg+-5deg c=2deg+-5deg

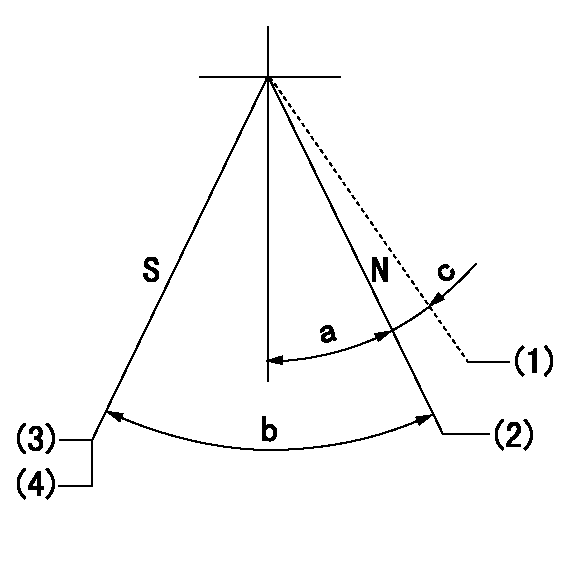

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Contacts normal side pin

(2)Distance from normal side pin = aa.

(3)Normal stop

(4)Rack position = bb or less, speed = cc

----------

aa=2.5+-0.5mm bb=7mm cc=0r/min

----------

a=27deg+-5deg b=53deg+-5deg c=(6deg)

----------

aa=2.5+-0.5mm bb=7mm cc=0r/min

----------

a=27deg+-5deg b=53deg+-5deg c=(6deg)

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Introduction

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

Fuel Injectors in 797F powered Off-Highway Trucks engines are not reaching expected mid-life target. The typical failure mode is a "-2" or a "-7" code on the fuel injectors.Solution

This will be an interim troubleshooting procedure to follow for trucks running with a special test software. Prior to executing this procedure, utilize Cat ® Electronic Technician (Cat ET) or Advisor to verify if any logged codes have been logged. Certain injector diagnostics do not notify the operator or light the check engine light upon activation."Fuel system verification-Test" procedure applies to trucks running with following software versions only.

Engine - LRC 3655600-31 (Test)

Engine - Tier II 5297866-05 (Test)

Engine - HAA (4x2) 3253178-39 (Test)

Engine - Tier II Custom 4727209-12 (Test)Troubleshooting Procedure

Table 1

Troubleshooting Test Steps Values Results

1. Check for Diagnostic Codes

A. Establish communication between Cat® (Electronic Technician) ET and the engine ECM. Cat ET must be configured for Dual Data Link Communications to perform this procedure. Refer to Troubleshooting, "Electronic Service Tools", if necessary.

B. Determine the diagnostic code that relates to an injector. Codes

Result: A -2 code is present.

Repair: Perform the following procedure:

1. Do not clear the diagnostic code.

Access the Fuel System Verification Test by accessing the following display screens:

- Diagnostics

- Diagnostic Tests

- Fuel System Verification Test

3. Perform the Fuel System Verification Test.

If the injector passes the test, the injector is "OK". Cat ET will clear the code.

Result: If the injector fails the test, perform the following procedure:

a. Replace the injector.

b. Flash program the trim file for the new injector into the ECM. Refer to Troubleshooting, "Injector Trim File - Install", if necessary.

c. Perform the Fuel System Verification Test again. This test will clear the active diagnostic code for the new injector. Verify that the original condition has been resolved.

Result: If the test

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

Fuel Injectors in 797F powered Off-Highway Trucks engines are not reaching expected mid-life target. The typical failure mode is a "-2" or a "-7" code on the fuel injectors.Solution

This will be an interim troubleshooting procedure to follow for trucks running with a special test software. Prior to executing this procedure, utilize Cat ® Electronic Technician (Cat ET) or Advisor to verify if any logged codes have been logged. Certain injector diagnostics do not notify the operator or light the check engine light upon activation."Fuel system verification-Test" procedure applies to trucks running with following software versions only.

Engine - LRC 3655600-31 (Test)

Engine - Tier II 5297866-05 (Test)

Engine - HAA (4x2) 3253178-39 (Test)

Engine - Tier II Custom 4727209-12 (Test)Troubleshooting Procedure

Table 1

Troubleshooting Test Steps Values Results

1. Check for Diagnostic Codes

A. Establish communication between Cat® (Electronic Technician) ET and the engine ECM. Cat ET must be configured for Dual Data Link Communications to perform this procedure. Refer to Troubleshooting, "Electronic Service Tools", if necessary.

B. Determine the diagnostic code that relates to an injector. Codes

Result: A -2 code is present.

Repair: Perform the following procedure:

1. Do not clear the diagnostic code.

Access the Fuel System Verification Test by accessing the following display screens:

- Diagnostics

- Diagnostic Tests

- Fuel System Verification Test

3. Perform the Fuel System Verification Test.

If the injector passes the test, the injector is "OK". Cat ET will clear the code.

Result: If the injector fails the test, perform the following procedure:

a. Replace the injector.

b. Flash program the trim file for the new injector into the ECM. Refer to Troubleshooting, "Injector Trim File - Install", if necessary.

c. Perform the Fuel System Verification Test again. This test will clear the active diagnostic code for the new injector. Verify that the original condition has been resolved.

Result: If the test

Have questions with 101602-2910?

Group cross 101602-2910 ZEXEL

Hino

Hino

101602-2910

INJECTION-PUMP ASSEMBLY