Information injection-pump assembly

BOSCH

9 400 610 578

9400610578

ZEXEL

101602-2861

1016022861

HINO

220204841A

220204841a

Rating:

Service parts 101602-2861 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-2133A

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 610 578

9400610578

ZEXEL

101602-2861

1016022861

HINO

220204841A

220204841a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.8

4.77

4.83

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

10

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

116.5

115

118

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Boost pressure

kPa

137

137

Boost pressure

mmHg

1030

1030

Injection quantity adjustment_02

Adjusting point

-

Rack position

6.8+-0.5

Pump speed

r/min

480

480

480

Average injection quantity

mm3/st.

10.5

9.5

11.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

R1-2

Boost pressure

kPa

66.7

64

69.4

Boost pressure

mmHg

500

480

520

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

R1(11.3)

Boost pressure

kPa

124

117.3

130.7

Boost pressure

mmHg

930

880

980

Test data Ex:

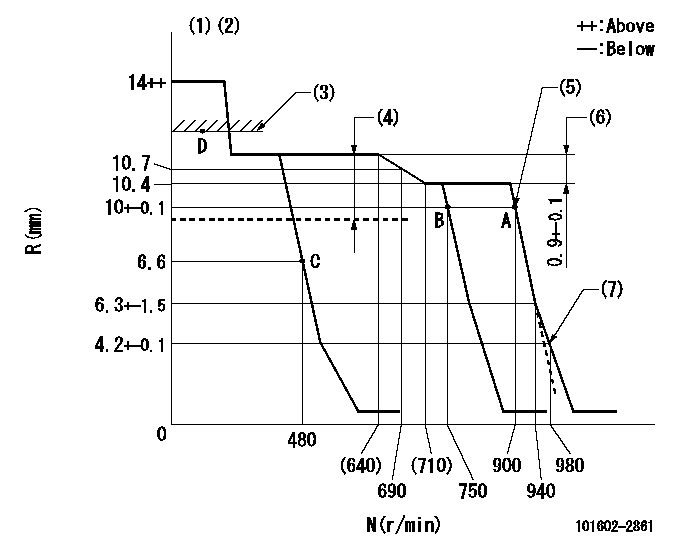

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Notch fixed: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator excessive fuel lever at operation (at 0 boost pressure): L1

(4)Boost compensator stroke: BCL

(5)Main spring setting

(6)Rack difference between N = N1 and N = N2

(7)Set idle sub-spring

----------

K=9 L1=12.9+-0.1mm BCL=2+-0.1mm N1=850r/min N2=500r/min

----------

----------

K=9 L1=12.9+-0.1mm BCL=2+-0.1mm N1=850r/min N2=500r/min

----------

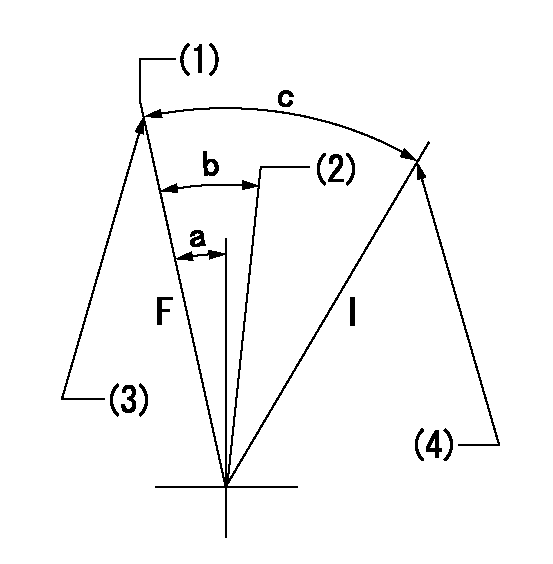

Speed control lever angle

F:Full speed

I:Idle

(1)Set the pump speed at aa. ( At delivery )

(2)When pump speed set at bb

(3)Stopper bolt setting

(4)Stopper bolt setting

----------

aa=900r/min bb=750r/min

----------

a=(1deg)+-5deg b=(5deg)+-5deg c=(18deg)+-5deg

----------

aa=900r/min bb=750r/min

----------

a=(1deg)+-5deg b=(5deg)+-5deg c=(18deg)+-5deg

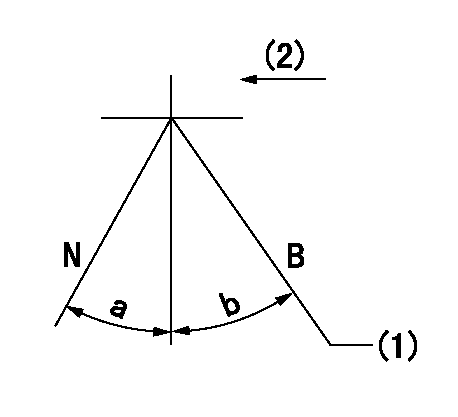

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position aa or less, pump speed bb

----------

aa=6.1mm bb=0r/min

----------

a=27deg+-5deg b=53deg+-5deg

----------

aa=6.1mm bb=0r/min

----------

a=27deg+-5deg b=53deg+-5deg

0000001101

N:Normal

B:When boosted

(1)Rack position = aa (point D) at boost pressure 0.

(2)Drive side

----------

aa=12.9+-0.1mm

----------

a=(15deg) b=(11deg)

----------

aa=12.9+-0.1mm

----------

a=(15deg) b=(11deg)

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

Bulk storage

Follow all local regulations covering bulk storage tanks. Follow proper tank construction guidelines. Tank volume typically should be 110% of planned capacity. Appropriately vent indoor tanks. Plan for control of overflow of the tank. Heat tanks that dispense DEF in cold climates.Bulk tank breathers should be fitted with filtration to keep airborne debris from entering the tank. Desiccant breathers should not be used because water will be absorbed, which potentially can alter DEF concentration.Handling

Follow all local regulations covering transport and handling. DEF transport temperature is recommended to be −5° C (23° F) to 25° C (77° F). All transfer equipment and intermediate containers should be used exclusively for DEF. Containers should not be reused for any other fluids. Ensure that transfer equipment is made from DEF-compatible materials. Recommended material for hoses and other non-metallic transfer equipment include:

Nitrile Rubber (NBR)

Fluoroelastomer (FKM)

Ethylene Propylene Diane Ionomer (EPDM)The condition of hoses and other nonmetallic items that are used with DEF should be monitored for signs of degradation. DEF leaks are easily recognizable by white urea crystals that accumulate at the site of the leak. Solid urea can be corrosive to galvanized or unalloyed steel, aluminum, copper, and brass. Leaks should be repaired immediately to avoid damage to surrounding hardware.Cleanliness

Contaminants can degrade the quality and life of DEF. Filtering DEF is recommended when dispensed into the DEF tank. Filters should be compatible with DEF and should be used exclusively with DEF. Check with the filter supplier to confirm compatibility with DEF before using. Mesh-type filters using compatible metals, such as stainless steel, are recommended. Paper (cellulose) media and some synthetic filter media are not recommended because of degradation during use.Care should be taken when dispensing DEF. Spills should be cleaned immediately. Machine or engine surfaces should be wiped clean and rinsed with water. Caution should be used when dispensing DEF near an engine that has recently been running.Note: Spilling DEF onto hot components may cause the release of ammonia vapors. Do not breathe ammonia vapors. Do not clean up any spills with bleach.Stability

DEF fluid is stable when stored and handled properly. The quality of DEF rapidly degrades when stored at high temperatures. The ideal storage temperature for DEF is between −9° C (15.8° F) and 25° C (77° F). DEF that is stored above 35° C (95° F) for longer than 1 month must be tested before use. Testing should evaluate Urea Percentage, Alkalinity as NH3 and Biuret content.The length of storage of DEF is listed in the following table:

Table 3

Storage Temperature Expected DEF Life

Below 25° C (77° F) 18 months

25° C (77° F) to 30° C (86° F) 12 months

30° C (86° F) to 35° C (95° F) 6 months

Above 35° C (95° F) test quality before use Refer to "ISO 22241" document series for more information about DEF quality control.Note: Dispose of all fluids according to applicable regulations and mandates.General Characteristics of DEF

For detailed information on the requirements and

Follow all local regulations covering bulk storage tanks. Follow proper tank construction guidelines. Tank volume typically should be 110% of planned capacity. Appropriately vent indoor tanks. Plan for control of overflow of the tank. Heat tanks that dispense DEF in cold climates.Bulk tank breathers should be fitted with filtration to keep airborne debris from entering the tank. Desiccant breathers should not be used because water will be absorbed, which potentially can alter DEF concentration.Handling

Follow all local regulations covering transport and handling. DEF transport temperature is recommended to be −5° C (23° F) to 25° C (77° F). All transfer equipment and intermediate containers should be used exclusively for DEF. Containers should not be reused for any other fluids. Ensure that transfer equipment is made from DEF-compatible materials. Recommended material for hoses and other non-metallic transfer equipment include:

Nitrile Rubber (NBR)

Fluoroelastomer (FKM)

Ethylene Propylene Diane Ionomer (EPDM)The condition of hoses and other nonmetallic items that are used with DEF should be monitored for signs of degradation. DEF leaks are easily recognizable by white urea crystals that accumulate at the site of the leak. Solid urea can be corrosive to galvanized or unalloyed steel, aluminum, copper, and brass. Leaks should be repaired immediately to avoid damage to surrounding hardware.Cleanliness

Contaminants can degrade the quality and life of DEF. Filtering DEF is recommended when dispensed into the DEF tank. Filters should be compatible with DEF and should be used exclusively with DEF. Check with the filter supplier to confirm compatibility with DEF before using. Mesh-type filters using compatible metals, such as stainless steel, are recommended. Paper (cellulose) media and some synthetic filter media are not recommended because of degradation during use.Care should be taken when dispensing DEF. Spills should be cleaned immediately. Machine or engine surfaces should be wiped clean and rinsed with water. Caution should be used when dispensing DEF near an engine that has recently been running.Note: Spilling DEF onto hot components may cause the release of ammonia vapors. Do not breathe ammonia vapors. Do not clean up any spills with bleach.Stability

DEF fluid is stable when stored and handled properly. The quality of DEF rapidly degrades when stored at high temperatures. The ideal storage temperature for DEF is between −9° C (15.8° F) and 25° C (77° F). DEF that is stored above 35° C (95° F) for longer than 1 month must be tested before use. Testing should evaluate Urea Percentage, Alkalinity as NH3 and Biuret content.The length of storage of DEF is listed in the following table:

Table 3

Storage Temperature Expected DEF Life

Below 25° C (77° F) 18 months

25° C (77° F) to 30° C (86° F) 12 months

30° C (86° F) to 35° C (95° F) 6 months

Above 35° C (95° F) test quality before use Refer to "ISO 22241" document series for more information about DEF quality control.Note: Dispose of all fluids according to applicable regulations and mandates.General Characteristics of DEF

For detailed information on the requirements and