Information injection-pump assembly

ZEXEL

101602-2860

1016022860

HINO

220204840A

220204840a

Rating:

Service parts 101602-2860 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-2133

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Cross reference number

ZEXEL

101602-2860

1016022860

HINO

220204840A

220204840a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.8

4.77

4.83

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

10

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

117

115.5

118.5

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Boost pressure

kPa

124

124

Boost pressure

mmHg

930

930

Injection quantity adjustment_02

Adjusting point

-

Rack position

6.9+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

10

9

11

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

R1-2.1

Boost pressure

kPa

52

49.3

54.7

Boost pressure

mmHg

390

370

410

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

R1(11.5)

Boost pressure

kPa

111

104.3

117.7

Boost pressure

mmHg

830

780

880

Test data Ex:

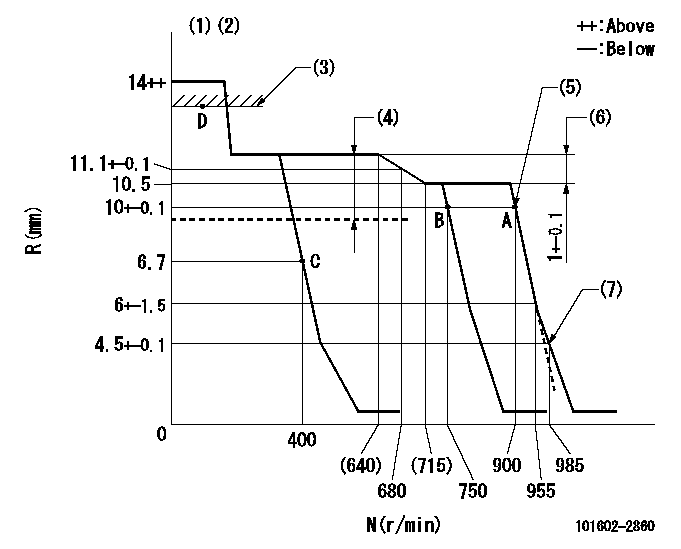

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Notch fixed: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Excessive fuel lever setting (boost pressure 0)

(4)Boost compensator stroke: BCL

(5)Main spring setting

(6)Rack difference between N = N1 and N = N2

(7)Set idle sub-spring

----------

K=10 BCL=2.1+-0.1mm N1=850r/min N2=500r/min

----------

----------

K=10 BCL=2.1+-0.1mm N1=850r/min N2=500r/min

----------

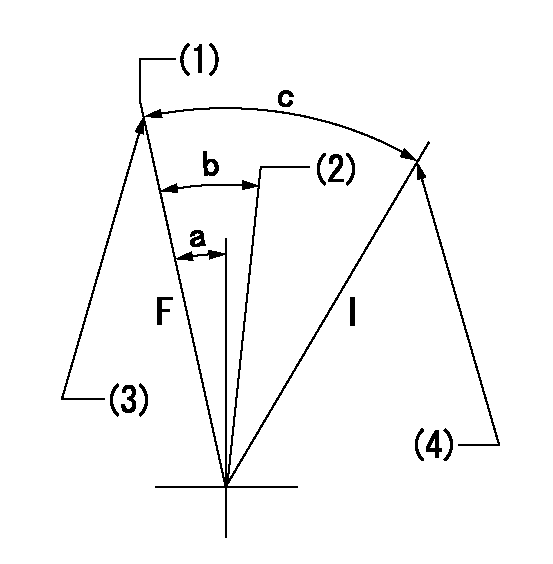

Speed control lever angle

F:Full speed

I:Idle

(1)Set the pump speed at aa. ( At delivery )

(2)When pump speed set at bb

(3)Stopper bolt setting

(4)Stopper bolt setting

----------

aa=900r/min bb=750r/min

----------

a=3deg+-5deg b=5.5deg+-5deg c=20deg+-5deg

----------

aa=900r/min bb=750r/min

----------

a=3deg+-5deg b=5.5deg+-5deg c=20deg+-5deg

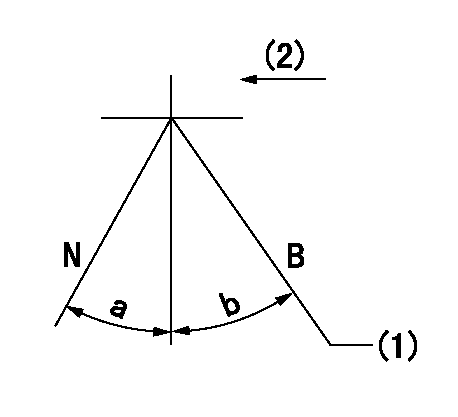

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position aa or less, pump speed bb

----------

aa=6.2mm bb=0r/min

----------

a=27deg+-5deg b=53deg+-5deg

----------

aa=6.2mm bb=0r/min

----------

a=27deg+-5deg b=53deg+-5deg

0000001101

N:Normal

B:When boosted

(1)Rack position = aa (point D) at boost pressure 0.

(2)Drive side

----------

aa=13.2+-0.1mm

----------

a=(15deg) b=(13deg)

----------

aa=13.2+-0.1mm

----------

a=(15deg) b=(13deg)

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

Every attempt is made to provide accurate, up-to-date information. By the use of this document, you agree that Caterpillar Inc. is not responsible for errors or omissions.

The information that is provided is the latest recommendations for Cat diesel engines that are covered by this Special Publication. This information supersedes all previous recommendations which have been published for Cat diesel engines that are covered by this Special Publication. Special fluids are required for some engines. These fluids will still be necessary in those engines. Refer to the applicable Operation and Maintenance Manual.This publication is a supplement to the Operation and Maintenance Manual. This publication does not replace the engine-specific Operation and Maintenance Manuals.

These recommendations are subject to change without notice. Consult your local Cat dealer for the most up to date recommendations.

Failure to follow the recommendations found in this Special Publication can cause engine failures, shortened engine service life, and reduced engine performance.In order to avoid potential damage to your Cat Cat engine, only purchase Cat fluids and Cat filters through your Cat dealer or Cat authorized outlets. For a list of authorized Cat parts outlets in your area, consult your Cat dealer.If you purchase what appear to be Cat fluids and/or Cat filters through other outlets/sources, you are at a very high risk of purchasing counterfeit (“look-alike”) products.Counterfeit or “look-alike” products may visually appear the same as the original Cat product. The product performance and internal quality will typically be very low.Counterfeit or “look-alike” products have a very high likelihood of causing and/or allowing engine and/or machine compartment damage.Many of the guidelines, recommendations, and requirements that are provided in this Special Publication are interrelated. Before using the provided information, The user is responsible to read this Special Publication and understand the information provided.The user is responsible to follow all safety guidelines found in this Special Publication and in the engine Operation and Maintenance Manual when performing all recommended and/or required engine, engine systems, and/or machine maintenance.For questions concerning the information presented in this Special Publication and/or in your product Operation and Maintenance Manual, and/or for additional guidelines and recommendations (including maintenance interval recommendations/requirements) consult your Cat dealer.Commercial products that make generic claims of meeting “Cat” and/or “Cat” requirements without listing the specific Cat recommendations and/or requirements that are met may not provide acceptable performance. Reduced engine and/or machine fluid compartment life may result. Refer to this Special Publication and refer to the product Operation and Maintenance Manual for Cat fluids recommendations and/or requirements.Use of fluids that do not meet at least the minimum performance recommendations and/or requirements may lead to lower compartment performance and/or compartment failure.Problems/failures that are caused by using fluids that do not meet the minimum recommended and/or required performance level for the compartment are not warrantable by Caterpillar Inc.. The fluid manufacturer and customer are responsible.When fluids made by other manufacturers are used on Cat products, the Cat warranty is not affected simply because of such use. Failures that result from the installation or usage