Information injection-pump assembly

BOSCH

9 400 619 550

9400619550

ZEXEL

101602-2841

1016022841

HINO

220204770B

220204770b

Rating:

Service parts 101602-2841 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 619 550

9400619550

ZEXEL

101602-2841

1016022841

HINO

220204770B

220204770b

Zexel num

Bosch num

Firm num

Name

9 400 619 550

220204770B HINO

INJECTION-PUMP ASSEMBLY

W06E-H * K 14BE PE6A PE

W06E-H * K 14BE PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.45

3.42

3.48

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

10

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

47.9

45.9

49.9

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

7.5+-0.5

Pump speed

r/min

450

450

450

Average injection quantity

mm3/st.

9

7.5

10.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

75

75

85

Fixing the lever

*

Rack limit

*

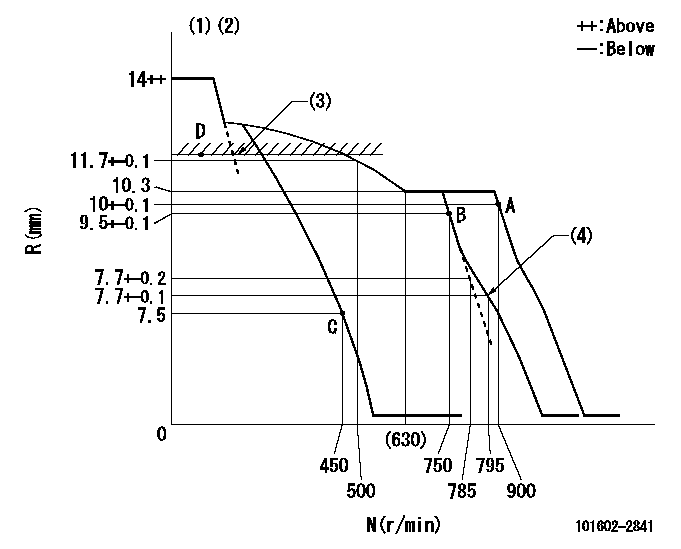

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

----------

K=15

----------

----------

K=15

----------

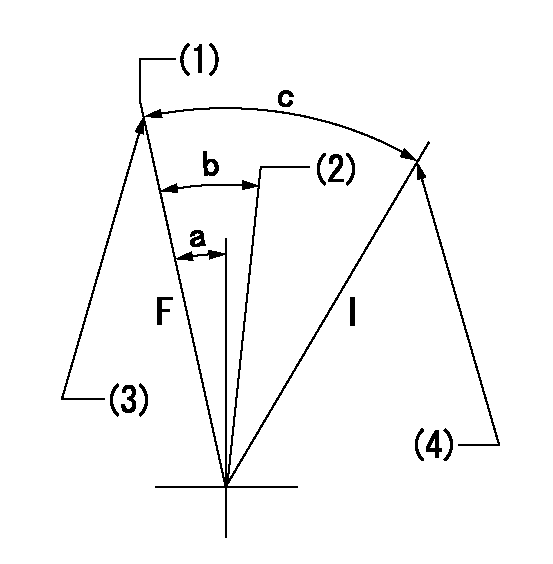

Speed control lever angle

F:Full speed

I:Idle

(1)Set the pump speed at aa

(2)When pump speed set at bb

(3)Stopper bolt setting

(4)Stopper bolt setting

----------

aa=900r/min bb=750r/min

----------

a=4deg+-5deg b=5deg+-5deg c=19deg+-5deg

----------

aa=900r/min bb=750r/min

----------

a=4deg+-5deg b=5deg+-5deg c=19deg+-5deg

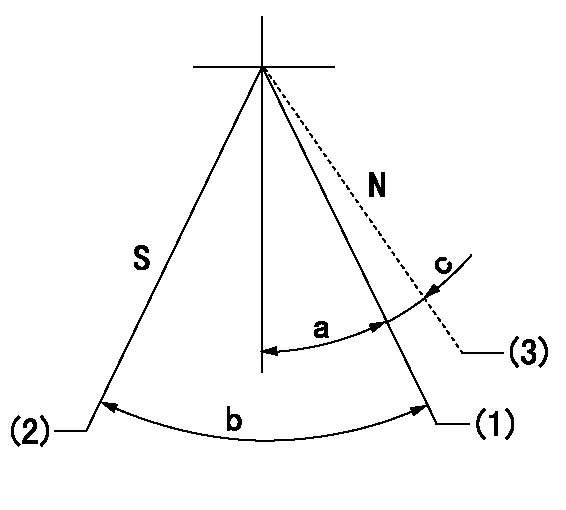

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Distance from normal side pin = aa.

(2)At shipping: rack position = bb or less, speed = cc.

(3)Contacts normal side pin

----------

aa=2.5+-0.5mm bb=7mm cc=0r/min

----------

a=27deg+-5deg b=53deg+-5deg c=(6deg)

----------

aa=2.5+-0.5mm bb=7mm cc=0r/min

----------

a=27deg+-5deg b=53deg+-5deg c=(6deg)

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Table 1

Features Benefits

All engineering changes and updates included Improved reliability and performance

Worldwide availability through the Cat® Parts Distribution System Customer access regardless of location

Off the shelf reliability Downtime reduced through exchanged product

Same as new Caterpillar warranty Consistent support

Illustration 1 g06211468

(1) Rocker arm with MEUI-A hardware

(2) Rocker arm with MEUI-C hardware

Table 2

MEUI-A Rocker MEUI-C Rocker

258-8721 Button 192-4151 Button

274-4492 Arm Adjustment Screw 196-5069 Arm Adjustment Screw

8L-2777 O-Ring Seal 061-8639 O-Ring Seal

Table 3

Reman Part Number New Part Number Engine Serial Number Prefixes

20R-3319 437-3881 115, 127, 132, 137, 173, 174, 175, 2A3, 3LW, 5DS, 7CZ, 8AZ, 9NN, 9YP, AL6, AN2, AR2, AR3, ASW, AT4, AZW, B2C, B3G, BEM, BFM, BGA, BXS, C1G, C2T, C4G, C5E, C5L, C6C, CAH, CCB, CE5, CKH, CWJ, DCT, DDS, DGK, DGL, DKE, DSJ, DWB, E1Y, GB3, GBM, GDS, GEN, GES, GRS, GSZ, GTB, HAZ, J2K, JAZ, JCF, JDA, JE9, JHL, JKG, JKS, JNZ, JSJ, K7C, KJT, KNM, KRA, L8D, LNA, LWR, LXJ, LXK, M1W, M1Y, M1Z, M7W, MCW, MDP, MED, MG2, MPE, MXS, N5F, NAW, NAY, NB2, NEW, NKL, NRC, NXS, P8B, PBL, PCY, PCZ, PEC, PEE, PEF, PEJ, PEK, PET, PHT, PHW, PKG, PKY, PKZ, R8W, RAM, RET, RGX, RLA, RNE, RNF, RNR, RNX, RNY, RNZ, RPM, RSD, RTK, S1P, SDN, SDP, SMP, SNW, SSM, STG, SXC, T3T, T4A, TG7, THS, TLD, TNA, TWM, W1A, WJB, WJY, WKB, X5M, XMJ, ZAG, ZKA, ZKB, ZP3, XP5

20R-3322 437-3862 176, 188, 1LW, 1MM, 2WS, 4AS, 5EK, 6BR, 6TB, 6TG, 6TS, 7T2, 9BZ, 9WR, B5R, BDN, BG4, BP2, BS9, C1J, C2A, C3G, C5H, CBX, CJP, CYN, CYY, DPG, DTP, DZE, EGH, EJG, EKW, EPE, F5C, F8N, G4C, GEX, GHJ, GJE, JAS, JDK, JDY, JEP, JKX, JLE, JRE, JWH, JZB, KCM, KEM, L8B, LDN, LET, LNB, LZA, LZB, MBN, MEP, MGS, MMB, N1C, N1D, NAP, NAX, NBB, NKK, PBN, PDM, PGN, PLE, RKS, RNC, RRC, RT2, RWS, SAY, SSW, STD, STM, SWE, T2P, T2R, TRB, WJA, WJH, WJW, WRH, X4R, XMK, Z2C, ZAY