Information injection-pump assembly

ZEXEL

101602-2840

1016022840

HINO

220204770A

220204770a

Rating:

Service parts 101602-2840 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-2142A

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Cross reference number

ZEXEL

101602-2840

1016022840

HINO

220204770A

220204770a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.45

3.42

3.48

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

10

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

47.9

45.9

49.9

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

7.5+-0.5

Pump speed

r/min

450

450

450

Average injection quantity

mm3/st.

9

7.5

10.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

75

75

85

Fixing the lever

*

Rack limit

*

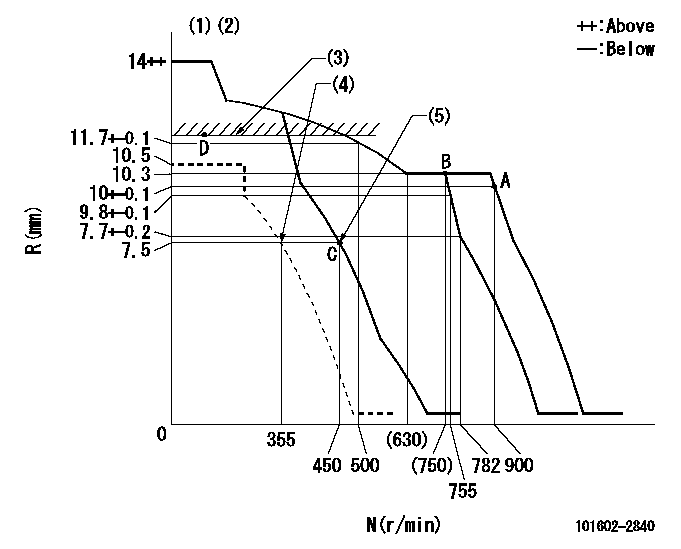

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

----------

K=9

----------

----------

K=9

----------

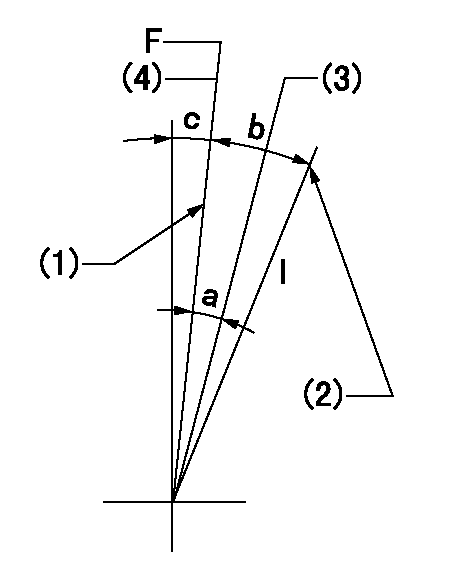

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)Stopper bolt setting

(3)When pump speed set at aa

(4)Set the pump speed at bb.

----------

aa=755r/min bb=900r/min

----------

a=5deg+-5deg b=18deg+-5deg c=1deg+-5deg

----------

aa=755r/min bb=900r/min

----------

a=5deg+-5deg b=18deg+-5deg c=1deg+-5deg

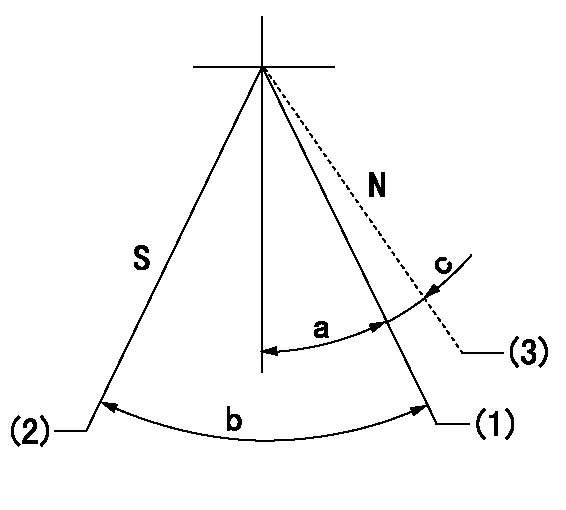

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Distance from normal side pin = aa.

(2)At shipping: rack position = bb or less, speed = cc.

(3)Contacts normal side pin

----------

aa=2.5+-0.5mm bb=7mm cc=0r/min

----------

a=27deg+-5deg b=53deg+-5deg c=(6deg)

----------

aa=2.5+-0.5mm bb=7mm cc=0r/min

----------

a=27deg+-5deg b=53deg+-5deg c=(6deg)

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Machine Preparation

Prepare the machine for maintenance.Refer to Operation and Maintenance Manual, SEBU8491, "Prepare the Machine for Maintenance".Removal Procedure

Illustration 2 g06215589

(A) 383-2040 Guard

(B) 8T-4195 Bolt

(C) 8T-4121 Hard Washer

(D) 384-0966 Insert

Remove and save the DEF guard (A), three bolts (B), three hard washers (C), and three inserts (D).

Illustration 3 g06217988

(C) 8T-4121 Hard Washer

(E) 368-4513 Side Plate

(F) 365-2227 Hose As

(G) 8T-4136 Bolt

(H) 1S-0994 Clip

(J) 8T-4137 Bolt

(K) 1S-1015 Clip

(L) 7K-1181 Cable Strap

Illustration 4 g06217851

(E) 368-4513 Side Plate

Illustration 5 g06219874

View of Area M

(C) 8T-4121 Hard Washer

(H) 1S-0994 Clip

(N) 399-3078 Machine Software Gp

(P) 434-1305 Insulation

(R) 326-4516 Cable Tie

(S) 8T-4195 Bolt

(T) 7X-7729 Washer

(U) 8T-4133 Nut

Remove six hard washers (C), two bolts (G), five clips (H), two bolts (J), clip (K), four cable straps (L), five cable ties (R), protective insulation (P), two bolts (S), two washers (T), and two nuts (U) from the hose assembly (F). Discard five clips (H), clip (K), five cable ties (R). Retain the rest of the parts.

Remove and discard hose assembly (F) from DEF tank and DEF Injector Mounting Gp (N). Refer to Illustration 3 and Illustration 5.Installation Procedure

Illustration 6 g06215872

(C) 8T-4121 Hard Washer

(G) 8T-4136 Bolt

(J) 8T-4137 Bolt

(1) 471-4171 Hose As

(2) 1S-0994 Clip

(3) 7K-1181 Cable Strap

(4) 1S-1015 Clip

Illustration 7 g06219875

View of Area M

(C) 8T-4121 Hard Washer

(N) 399-6078 DEF Injector & Mounting Gp

(P) 434-1305 Insulation

(S) 8T-4195 Bolt

(T) 7X-7729 Washer

(U) 8T-4133 Nut

(1) 471-4171 Hose As

(2) 1S-0994 Clip

(5) 326-4516 Cable Tie

Install new hose assembly (1) to the DEF tank and DEF injector mounting group (N). Secure hose assembly (1) using five clips (2), four cable straps (3), clip (4), six hard washers (C), two bolts (G), two bolts (J), two bolts (S), two washers (T), and two nuts (U) that were saved in Step 2 of Section "Removal Procedure". Refer to Illustration 6 and Illustration 7.

Secure protective insulation (P) that was saved in Step 2 of Section "Removal Procedure" to hose assembly (1) using five cable ties (5). Refer to Illustration 7.

Illustration 8 g06215593

(A) 383-2040 Guard

(V) Template

Illustration 9 g06215595

(X) 94.4 mm (3.72 inch)

(Y) 225 mm (8.9 inch)

Use Illustration 9 as a template and position the template onto guard (A), aligning to the edges. Trim the guard (A) according to the template. Refer to Illustration 8.Note: Lay the template flat on the guard. The trimmed area of the guard (A) is the curved area. The square cutout on the template is not to be cut, the square corner allows the template to lay flatter on the guard.

Illustration 10 g06215889

(A) 383-2040 Guard

(E) 368-4513 Side Plate

(1) 471-4171 Hose As

Install the modified DEF guard (A) using the hardware that was saved in Step 1 of Section "Removal Procedure".Note: Ensure adequate clearance has been obtained.

Return machine to service.

Prepare the machine for maintenance.Refer to Operation and Maintenance Manual, SEBU8491, "Prepare the Machine for Maintenance".Removal Procedure

Illustration 2 g06215589

(A) 383-2040 Guard

(B) 8T-4195 Bolt

(C) 8T-4121 Hard Washer

(D) 384-0966 Insert

Remove and save the DEF guard (A), three bolts (B), three hard washers (C), and three inserts (D).

Illustration 3 g06217988

(C) 8T-4121 Hard Washer

(E) 368-4513 Side Plate

(F) 365-2227 Hose As

(G) 8T-4136 Bolt

(H) 1S-0994 Clip

(J) 8T-4137 Bolt

(K) 1S-1015 Clip

(L) 7K-1181 Cable Strap

Illustration 4 g06217851

(E) 368-4513 Side Plate

Illustration 5 g06219874

View of Area M

(C) 8T-4121 Hard Washer

(H) 1S-0994 Clip

(N) 399-3078 Machine Software Gp

(P) 434-1305 Insulation

(R) 326-4516 Cable Tie

(S) 8T-4195 Bolt

(T) 7X-7729 Washer

(U) 8T-4133 Nut

Remove six hard washers (C), two bolts (G), five clips (H), two bolts (J), clip (K), four cable straps (L), five cable ties (R), protective insulation (P), two bolts (S), two washers (T), and two nuts (U) from the hose assembly (F). Discard five clips (H), clip (K), five cable ties (R). Retain the rest of the parts.

Remove and discard hose assembly (F) from DEF tank and DEF Injector Mounting Gp (N). Refer to Illustration 3 and Illustration 5.Installation Procedure

Illustration 6 g06215872

(C) 8T-4121 Hard Washer

(G) 8T-4136 Bolt

(J) 8T-4137 Bolt

(1) 471-4171 Hose As

(2) 1S-0994 Clip

(3) 7K-1181 Cable Strap

(4) 1S-1015 Clip

Illustration 7 g06219875

View of Area M

(C) 8T-4121 Hard Washer

(N) 399-6078 DEF Injector & Mounting Gp

(P) 434-1305 Insulation

(S) 8T-4195 Bolt

(T) 7X-7729 Washer

(U) 8T-4133 Nut

(1) 471-4171 Hose As

(2) 1S-0994 Clip

(5) 326-4516 Cable Tie

Install new hose assembly (1) to the DEF tank and DEF injector mounting group (N). Secure hose assembly (1) using five clips (2), four cable straps (3), clip (4), six hard washers (C), two bolts (G), two bolts (J), two bolts (S), two washers (T), and two nuts (U) that were saved in Step 2 of Section "Removal Procedure". Refer to Illustration 6 and Illustration 7.

Secure protective insulation (P) that was saved in Step 2 of Section "Removal Procedure" to hose assembly (1) using five cable ties (5). Refer to Illustration 7.

Illustration 8 g06215593

(A) 383-2040 Guard

(V) Template

Illustration 9 g06215595

(X) 94.4 mm (3.72 inch)

(Y) 225 mm (8.9 inch)

Use Illustration 9 as a template and position the template onto guard (A), aligning to the edges. Trim the guard (A) according to the template. Refer to Illustration 8.Note: Lay the template flat on the guard. The trimmed area of the guard (A) is the curved area. The square cutout on the template is not to be cut, the square corner allows the template to lay flatter on the guard.

Illustration 10 g06215889

(A) 383-2040 Guard

(E) 368-4513 Side Plate

(1) 471-4171 Hose As

Install the modified DEF guard (A) using the hardware that was saved in Step 1 of Section "Removal Procedure".Note: Ensure adequate clearance has been obtained.

Return machine to service.