Information injection-pump assembly

BOSCH

9 400 610 574

9400610574

ZEXEL

101602-2810

1016022810

Rating:

Service parts 101602-2810 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-2142A

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 610 574

9400610574

ZEXEL

101602-2810

1016022810

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.45

3.42

3.48

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

10

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

47

45

49

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.8+-0.5

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

9

7.5

10.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

115

115

125

Fixing the lever

*

Rack limit

*

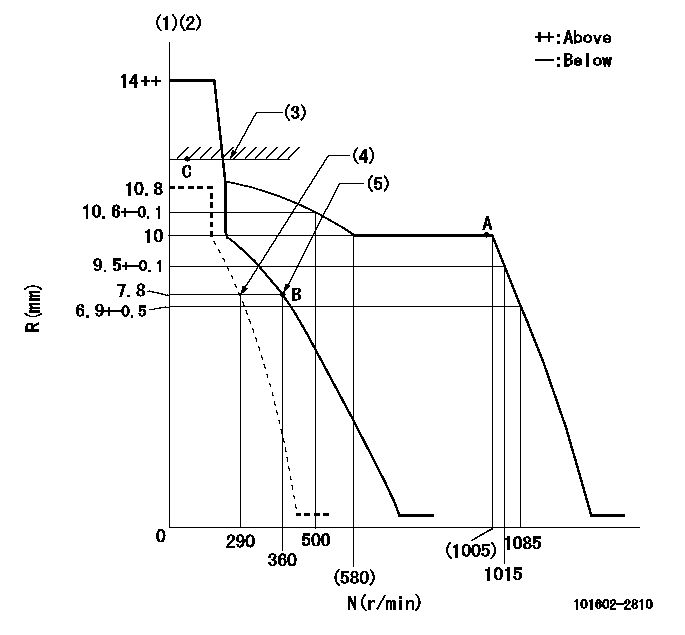

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

----------

K=11

----------

----------

K=11

----------

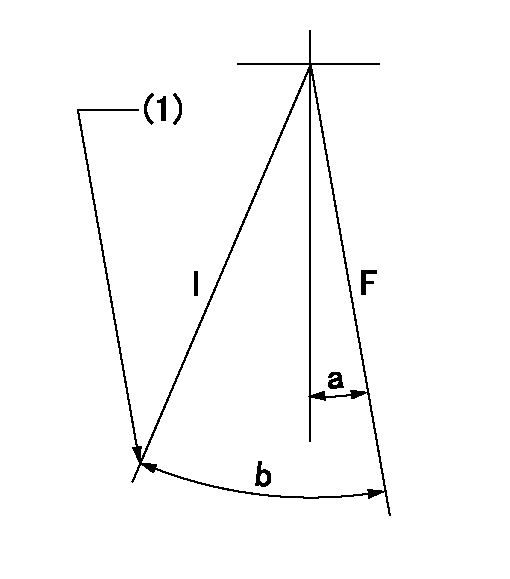

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=1deg+-5deg b=17deg+-5deg

----------

----------

a=1deg+-5deg b=17deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position aa or less, pump speed bb

----------

aa=7.3mm bb=0r/min

----------

a=27deg+-5deg b=53deg+-5deg

----------

aa=7.3mm bb=0r/min

----------

a=27deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Use of Cat Diesel Fuel System Cleaner or Cat Diesel Fuel System Conditioner does not lessen the responsibility of the engine owner and/or responsibility of the fuel supplier to follow all industry standard maintenance practices for fuel storage and for fuel handling. Refer to the “General Fuel Information” article in this Special Publication for additional information. Additionally, use of Cat Diesel Fuel System Cleaner or Cat Diesel Fuel System Conditioner does NOT lessen the responsibility of the owner of the engine to use appropriate diesel fuel. Refer to the “Fuel Specifications” section in this Special Publication (Maintenance Section) for guidance.

Cat strongly recommends the use of Cat Diesel Fuel Conditioner with biodiesel and biodiesel blends. Cat Diesel Fuel Conditioner is suitable for use with biodiesel/biodiesel blends that meet Cat biodiesel recommendations and requirements. Not all fuel additives are suitable for use with biodiesel/biodiesel blends. Read and follow all applicable label usage instructions. Also, refer to this Special Publication, "Distillate Diesel Fuel" article and also refer to the “Biodiesel” article, which includes Cat biodiesel recommendations and requirements.Cat Diesel Fuel Conditioner has proven to be compatible with existing and U.S. EPA 2007 on-highway certified diesel engine emission control catalysts and particulate filters.Note: When used as directed, Cat Diesel Fuel Conditioner will not raise fuel sulfur levels measurably in the final fuel/additive blend. In the U.S. the current formulation of Cat Diesel Fuel Conditioner must be blended in at the recommended treat-rate at the fuel supplier/distributor level for use in on-highway or other applications where use of ULSD fuel is mandated (15 ppm or less fuel sulfur). Follow all applicable national, regional, and local laws, mandates, and regulations concerning the use of diesel fuel conditioners/additives.

When used as directed Cat Diesel Fuel Conditioner will not raise fuel sulfur levels measurably in the final fuel/additive blend. Follow all applicable national, regional, and local laws, mandates, and regulations concerning the use of diesel fuel conditioners/additives.

Cat Diesel Fuel System Cleaner

Note: Cat Diesel Fuel System Cleaner, part number 343-6210, is the only fuel system cleaner available to the end user that is tested and approved by Cat for use in Cat diesel engines.Cat Diesel Fuel System Cleaner is a proven high performance detergent product designed for cleaning deposits that form in the fuel system. Deposits in the fuel system reduce system performance and can increase fuel consumption. Cat Diesel Fuel System Cleaner addresses the deposits formed due to the use of degraded diesel fuel, poor quality diesel fuel, and diesel fuel containing high quantities of high molecular weight compounds. Cat Diesel Fuel System Cleaner addresses deposits formed due to the use of biodiesel, biodiesel blends, and biodiesel that does not meet the appropriate quality specifications. Continued use of Cat Diesel Fuel System Cleaner is proven to inhibit the growth of new deposits.Cat Diesel Fuel System Cleaner can be added directly to diesel fuel, biodiesel, or biodiesel blends. Cat Diesel Fuel System Cleaner is a United States Environmental Protection Agency registered fuel additive that can be used with