Information injection-pump assembly

ZEXEL

101602-2710

1016022710

HINO

220204220A

220204220a

Rating:

Cross reference number

ZEXEL

101602-2710

1016022710

HINO

220204220A

220204220a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.8

3.77

3.83

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

10.7

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

85.5

83.5

87.5

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

8.2+-0.5

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

13

12

14

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

100

100

110

Fixing the lever

*

Rack limit

*

Test data Ex:

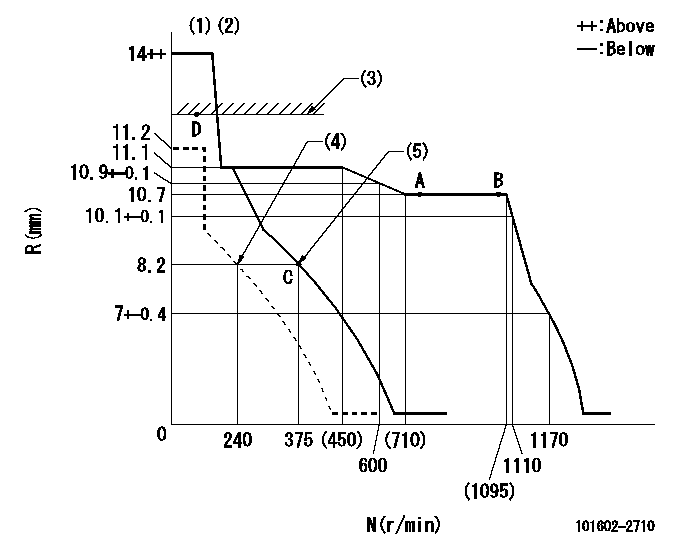

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

----------

K=15

----------

----------

K=15

----------

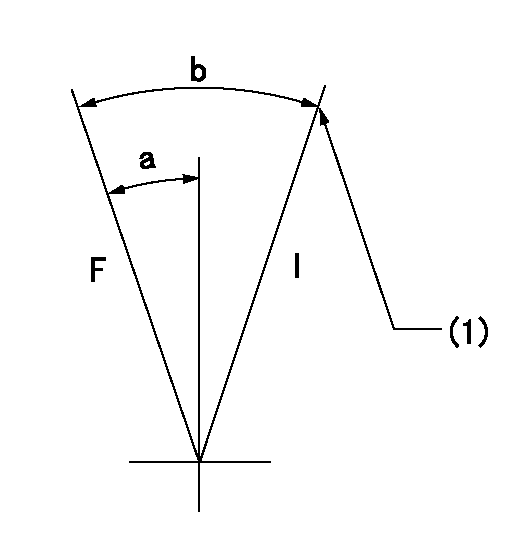

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=13deg+-5deg b=27deg+-5deg

----------

----------

a=13deg+-5deg b=27deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position aa or less, pump speed bb

----------

aa=7.7mm bb=0r/min

----------

a=27deg+-5deg b=53deg+-5deg

----------

aa=7.7mm bb=0r/min

----------

a=27deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

Introduction

This Special Instruction addresses the issue about the amount of ash in the DPF, and whether the DPF must be cleaned. Use the following procedure in order to determine if the DPF must be cleaned.Procedure

Note: This test is not designed to determine if a DPF is clean, only to determine if the DPF must be cleaned.

Perform a crack detection test. Refer to Special Instruction, REHS5017. Go to Step 2 if the DPF passes the crack detection test. Contact the Technical Communicator, if the DPF fails the test

Use a wire with the maximum diameter of 1.04140 mm (0.041 inch). Hold the wire so that the end of the wire is just inside the cell approximately 6.35000 mm (0.25 inch).

Drop the wire into the cell of the DPF.

Mark the wire at the top of the cell where the wire exits from the DPF.

Measure the depth that the wire dropped by measuring from the mark to the bottom tip of the wire.

Record the measurement.

Illustration 1 g03021156

Top view of DPFView of locations for recording measurements (1) Weld line

Perform Steps 3 through 6 for all locations. Refer to Illustration 1 for the proper location for recording measurements.

Average the measurements and subtract the average from the length of the DPF substrate length. The DPF must be cleaned if the number is more than 6 inches. Replace the DPF if the DPF cannot be cleaned.

This Special Instruction addresses the issue about the amount of ash in the DPF, and whether the DPF must be cleaned. Use the following procedure in order to determine if the DPF must be cleaned.Procedure

Note: This test is not designed to determine if a DPF is clean, only to determine if the DPF must be cleaned.

Perform a crack detection test. Refer to Special Instruction, REHS5017. Go to Step 2 if the DPF passes the crack detection test. Contact the Technical Communicator, if the DPF fails the test

Use a wire with the maximum diameter of 1.04140 mm (0.041 inch). Hold the wire so that the end of the wire is just inside the cell approximately 6.35000 mm (0.25 inch).

Drop the wire into the cell of the DPF.

Mark the wire at the top of the cell where the wire exits from the DPF.

Measure the depth that the wire dropped by measuring from the mark to the bottom tip of the wire.

Record the measurement.

Illustration 1 g03021156

Top view of DPFView of locations for recording measurements (1) Weld line

Perform Steps 3 through 6 for all locations. Refer to Illustration 1 for the proper location for recording measurements.

Average the measurements and subtract the average from the length of the DPF substrate length. The DPF must be cleaned if the number is more than 6 inches. Replace the DPF if the DPF cannot be cleaned.