Information injection-pump assembly

BOSCH

9 400 614 791

9400614791

ZEXEL

101602-2700

1016022700

HINO

220203990A

220203990a

Rating:

Service parts 101602-2700 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-1710

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 614 791

9400614791

ZEXEL

101602-2700

1016022700

HINO

220203990A

220203990a

Zexel num

Bosch num

Firm num

Name

101602-2700

9 400 614 791

220203990A HINO

INJECTION-PUMP ASSEMBLY

W06D-T K

W06D-T K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.3

3.25

3.35

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.1

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

65.3

62.3

68.3

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.1+-0.5

Pump speed

r/min

315

315

315

Average injection quantity

mm3/st.

9.6

8.1

11.1

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

106

106

116

Fixing the lever

*

Rack limit

*

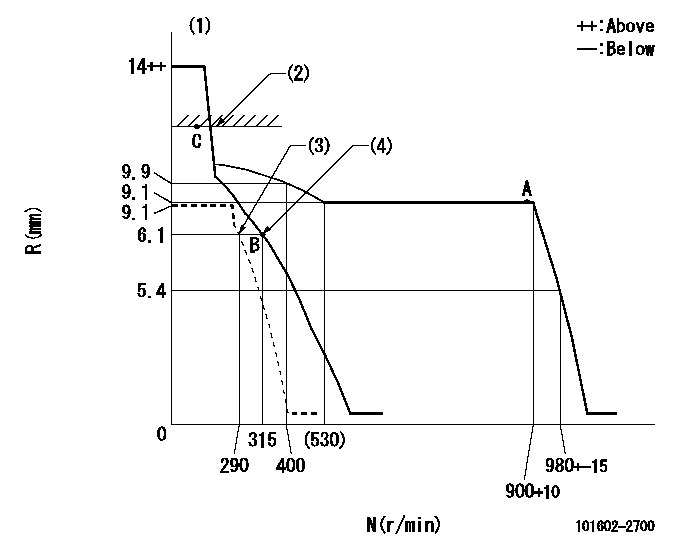

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT

(3)Set idle sub-spring

(4)Main spring setting

----------

K=8

----------

----------

K=8

----------

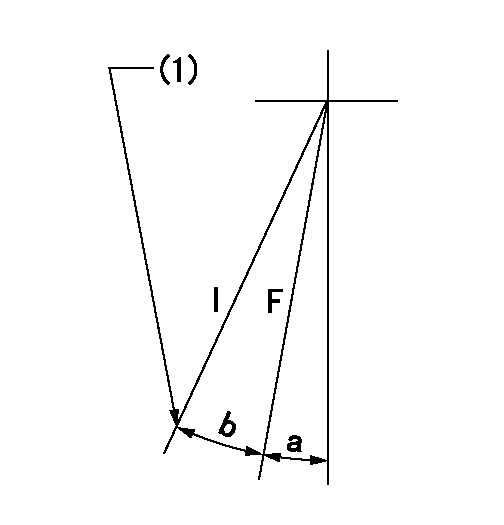

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=5deg+-5deg b=20deg+-5deg

----------

----------

a=5deg+-5deg b=20deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position aa or less, pump speed bb

----------

aa=5.6mm bb=0r/min

----------

a=27deg+-5deg b=53deg+-5deg

----------

aa=5.6mm bb=0r/min

----------

a=27deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Do not operate or work on this machine unless you have read and understand the instructions and warnings in the Operation and Maintenance Manual. Failure to follow the instructions or heed the warnings could result in injury or death. Contact your Caterpillar dealer for replacement manuals. Proper care is your responsibility.

Personal injury or death can result from improper assembly procedures.Do not attempt any assembly until you have read and understand the assembly instructions.

Accidental engine starting can cause injury or death to personnel working on the equipment.To avoid accidental engine starting, disconnect the battery cable from the negative (−) battery terminal. Completely tape all metal surfaces of the disconnected battery cable end in order to prevent contact with other metal surfaces which could activate the engine electrical system.Place a Do Not Operate tag at the Start/Stop switch location to inform personnel that the equipment is being worked on.

Required Parts

Table 1

Required Tools

Tool Part Number Part Name Qty

A 9S-9150 Terminal Crimp Tool As 1

B 9U-6070 Heat Gun Gp 1 Removal of a Connector from the Wire Harness

The following steps can be used to remove a connector for an injector on the wire harness.

Identify the connectors that need to be replaced. Wiring for the injector solenoid is not sensitive to polarity.

Illustration 1 g06093848

Connectors that are cut from the wire harness

Each injector will have two connectors. The wire on one connector will be longer than the other. Wire (A) is identified as the longer wire and wire (B) is identified as the shorter wire.

Cut wire (2) at a distance of 50 mm (1.9 inch) from the rear surface of the connector.

Cut wire (1) at a distance of 5 mm (0.2 inch) from the cut made on wire (2).

Illustration 2 g01111314

Wire from the harness for side (B) on the connector.

Wire from the harness for side (A) on the connector.Note: The wires on the old connector are cut to length so that the wires on the wire harness will match up to the new connector. Cutting the wires to the proper length will aid in matching the harness wires to the wires on the new connector.

Discard the old connectors.Installation of a New Connector

The following steps can be used to install a new connector for an injector on the wire harness that is located under the valve mechanism cover.

Use Tool (A) to remove 5 mm (0.2 inch) of the plastic from wires (3) and (4).

Illustration 3 g06125254

Connecting the connector to the wire harness

(A) Side (A) of the new connector

(B) Side (B) of the new connector

(3) Wire from the harness for side (B) on the new connector

(4) Wire from the harness for side (A) on the new connector

(5) Heat shrink tubes

(6) Butt splice on the wire that is on side (A) of the new connector

(7) Butt splice on the wire that is on side (B) of the new connector

Use heat shrink tubes (5) from the 257-4183 Injector Wiring Harness Kit. Slide the heat shrink tubes toward the connector to expose the butt splices.

Insert wire (4) into

Have questions with 101602-2700?

Group cross 101602-2700 ZEXEL

Hino

101602-2700

9 400 614 791

220203990A

INJECTION-PUMP ASSEMBLY

W06D-T

W06D-T