Information injection-pump assembly

BOSCH

9 400 614 786

9400614786

ZEXEL

101602-2650

1016022650

HINO

220203890A

220203890a

Rating:

Service parts 101602-2650 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-1710

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 614 786

9400614786

ZEXEL

101602-2650

1016022650

HINO

220203890A

220203890a

Zexel num

Bosch num

Firm num

Name

101602-2650

9 400 614 786

220203890A HINO

INJECTION-PUMP ASSEMBLY

W06D-T K

W06D-T K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.3

3.25

3.35

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.1

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

72.2

69.2

75.2

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.1+-0.5

Pump speed

r/min

315

315

315

Average injection quantity

mm3/st.

9.6

8.1

11.1

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

106

106

116

Fixing the lever

*

Rack limit

*

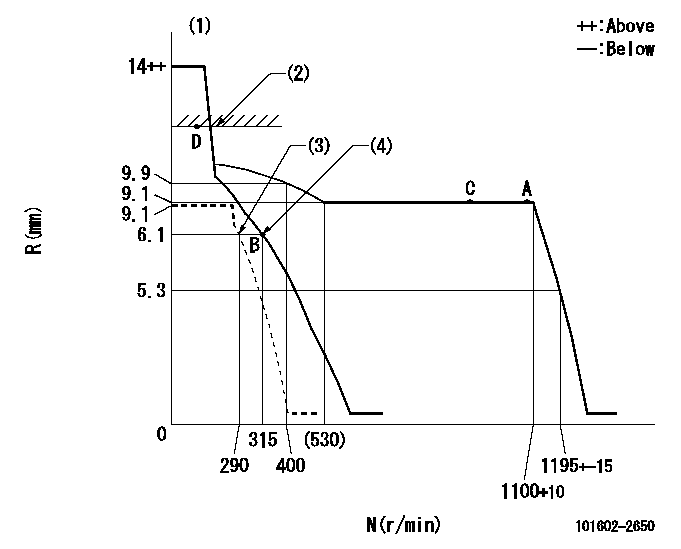

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT

(3)Set idle sub-spring

(4)Main spring setting

----------

K=10

----------

----------

K=10

----------

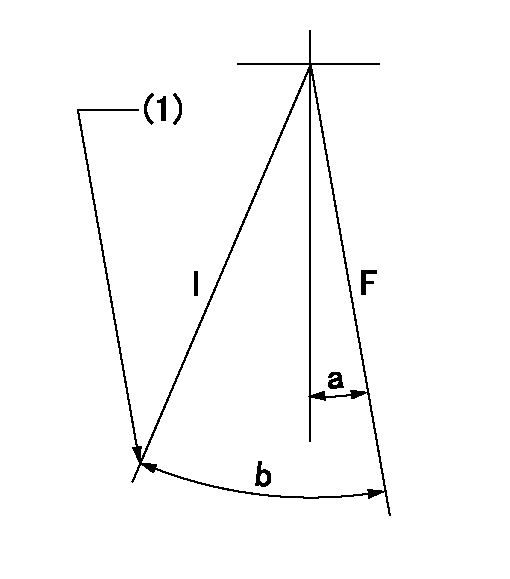

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=1deg+-5deg b=21deg+-5deg

----------

----------

a=1deg+-5deg b=21deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position aa or less, pump speed bb

----------

aa=5.6mm bb=0r/min

----------

a=27deg+-5deg b=53deg+-5deg

----------

aa=5.6mm bb=0r/min

----------

a=27deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Repeat Steps 4 through 6 to remove (bleed) air from the rear table lift cylinder (not shown).

Open (CCW) hand pump control knob (11) to completely lower the DPF cleaner table. Close (CW) the hand pump control knob.

Illustration 38 g02728258

(28) Hydraulic Oil Level 51 to 102 mm (2.0 to 4.0 inch)

Check the oil level in the pump reservoir. Remove fill cap (13) located on the end cap of the hand pump. Hydraulic oil level (28) should be 51 to 102 mm (2.0 to 4.0 inch) from the bottom of the fill hole. Add high-grade hydraulic oil, if needed.Note: A clean wire tie can be used as a dipstick to measure the hydraulic oil level in the pump reservoir.Troubleshooting Guide

Table 3

Symptom Solution

Air dryer desiccant is a pinkish color. 1. Replace or regenerate the desiccant. Refer to ""Maintenance Section"".

Bursting does not occur. 1. Check display screen for error message.

2. Check power connection to burst valve solenoid.

Cabinet doors do not close correctly. 1. Look for damaged door hinges, seals, and latches.

2. Verify that vehicle sensors have been removed from DPF.

Cabinet doors open during burst process. 1. Verify that doors are correctly latched.

2. Look for damage to door latches.

3. Check seals between DPF and adapters.

Clamping force cannot be obtained. 1. Look for hydraulic fluid leaks.

2. Check fluid level in hydraulic pump. Refer to ""Maintenance Section"".

Clamping force does not hold. 1. Upon initial clamping, it is possible for clamp load to drop

689 to 1379 kPa (99.9 to 200.0 psi) within the first minute, due to temperature effects. After reclamping, the drop should be virtually zero.

2. Look for hydraulic fluid leaks.

Display screen is blank. 1. Verify that machine is ON, plugged into an outlet, and power is available to the outlet.

2. Reset circuit breakers located on left side of control cabinet.

DPF does not line up correctly on the table. 1. Verify that correct adapters are being used.

2. Verify DPF is correctly seated on to lower adapter.

DPF is damaged after cleaning process. 1. Check DPFs for damage before cleaning.

2. Look for damage on adapters.

3. Verify that correct cleaning protocol was entered into machine.

DPF is not cleaned. 1. Check orientation of DPF. Refer to ""General Information"" Section.

2. Verify that correct cleaning protocol was entered into machine.

3. Look for other DPF conditions that may prevent successful cleaning.

Have questions with 101602-2650?

Group cross 101602-2650 ZEXEL

Hino

Hino

101602-2650

9 400 614 786

220203890A

INJECTION-PUMP ASSEMBLY

W06D-T

W06D-T