Information injection-pump assembly

BOSCH

9 400 614 785

9400614785

ZEXEL

101602-2643

1016022643

HINO

220801563A

220801563a

Rating:

Include in #1:

101472-0061

as _

Cross reference number

BOSCH

9 400 614 785

9400614785

ZEXEL

101602-2643

1016022643

HINO

220801563A

220801563a

Zexel num

Bosch num

Firm num

Name

101602-2643

9 400 614 785

220801563A HINO

INJECTION-PUMP ASSEMBLY

W06D K

W06D K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

RED3 control unit part number

407910-2

470

RED3 rack sensor specifications

mm

15

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.1

3.05

3.15

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Rack position

(8.1)

Vist

V

2.38

2.38

2.38

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

49.7

47.7

51.7

Max. variation between cylinders

%

0

-3

3

Basic

*

Injection quantity adjustment_02

Rack position

(5.8)

Vist

V

2.8

2.7

2.9

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

9

7.5

10.5

Max. variation between cylinders

%

0

-15

15

Test data Ex:

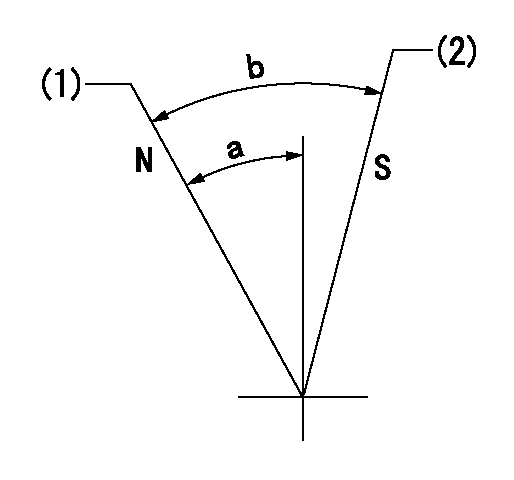

Speed control lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

----------

aa=16mm bb=1mm

----------

a=19deg+-5deg b=29deg+-5deg

----------

aa=16mm bb=1mm

----------

a=19deg+-5deg b=29deg+-5deg

0000000901

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Stop lever angle

(Rs) rack sensor specifications

(C/U) control unit part number

(V) Rack sensor output voltage

(R) Rack position (mm)

1. Confirming governor output characteristics (rack 15 mm, span 6 mm)

(1)When the output voltages of the rack sensor are V1 and V2, check that the rack positions R1 and R2 in the table above are satisfied.

----------

----------

----------

----------

Information:

Installation Procedure

Table 1

Required Parts

Item Qty Part Number Description

1 1 285-1163 Cable

2 1 493-6051 Cover

3 1 5P-7958 Cable Splice Sleeve

Prepare the machine for maintenance. Refer to Operation and Maintenance Manual, "Prepare the Machine for Maintenance".

Illustration 1 g06048101

View of the Diesel Exhaust Fluid (DEF) tank

(A) Bolt

(1) 285-1163 Cable

Remove and retain bolt (A) that secures the cover to the fuel tank.

Secure cable (1) around bolt (A) and reinstall bolt (A).

Illustration 2 g06048083

View of the Diesel Exhaust Fluid (DEF) tank

(1) 285-1163 Cable

(2) 493-6051 Cover

(3) 5P-7958 Cable Splice Sleeve

Slide cover (2) over the fill tube on the tank.Insert the loose end of cable (1) through the hole of cover (2).Secure cable (1) with cable splice sleeve (3).

Table 1

Required Parts

Item Qty Part Number Description

1 1 285-1163 Cable

2 1 493-6051 Cover

3 1 5P-7958 Cable Splice Sleeve

Prepare the machine for maintenance. Refer to Operation and Maintenance Manual, "Prepare the Machine for Maintenance".

Illustration 1 g06048101

View of the Diesel Exhaust Fluid (DEF) tank

(A) Bolt

(1) 285-1163 Cable

Remove and retain bolt (A) that secures the cover to the fuel tank.

Secure cable (1) around bolt (A) and reinstall bolt (A).

Illustration 2 g06048083

View of the Diesel Exhaust Fluid (DEF) tank

(1) 285-1163 Cable

(2) 493-6051 Cover

(3) 5P-7958 Cable Splice Sleeve

Slide cover (2) over the fill tube on the tank.Insert the loose end of cable (1) through the hole of cover (2).Secure cable (1) with cable splice sleeve (3).

Have questions with 101602-2643?

Group cross 101602-2643 ZEXEL

Hino

Hino

101602-2643

9 400 614 785

220801563A

INJECTION-PUMP ASSEMBLY

W06D

W06D