Information injection-pump assembly

BOSCH

9 400 614 778

9400614778

ZEXEL

101602-2510

1016022510

HINO

220203540A

220203540a

Rating:

Service parts 101602-2510 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-1171

12.

Open Pre:MPa(Kqf/cm2)

18.1{185}

15.

NOZZLE SET

Include in #1:

101602-2510

as INJECTION-PUMP ASSEMBLY

Include in #2:

104278-1190

as _

Cross reference number

BOSCH

9 400 614 778

9400614778

ZEXEL

101602-2510

1016022510

HINO

220203540A

220203540a

Zexel num

Bosch num

Firm num

Name

101602-2510

9 400 614 778

220203540A HINO

INJECTION-PUMP ASSEMBLY

EL100 * K 14BF PE6AD PE

EL100 * K 14BF PE6AD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.85

4.8

4.9

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

7.7

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

82

80.4

83.6

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

4.4+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

9.5

8

11

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Test data Ex:

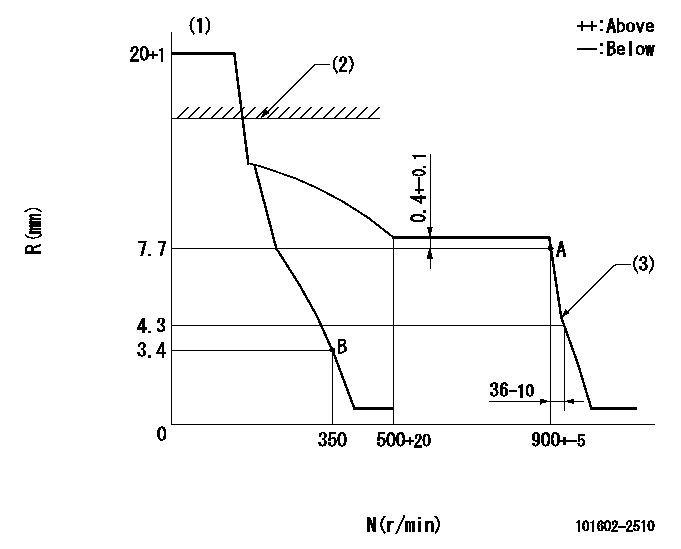

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT: RAL

(3)Idle sub spring setting: L1.

----------

K=4 RAL=14+0.2mm L1=4.5+-0.2mm

----------

----------

K=4 RAL=14+0.2mm L1=4.5+-0.2mm

----------

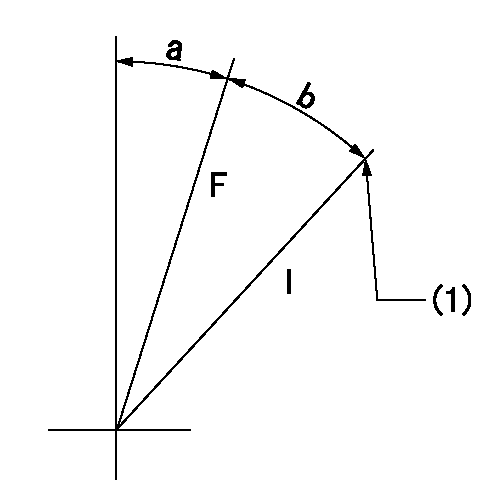

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=3deg+-5deg b=21deg+-5deg

----------

----------

a=3deg+-5deg b=21deg+-5deg

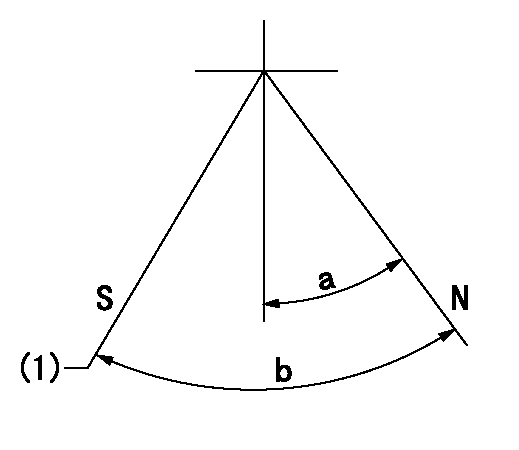

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)At shipping

----------

----------

a=38deg+-5deg b=53deg+-5deg

----------

----------

a=38deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

Illustration 6 g06613192

Gray locking wedge removed from ECM connector

Remove gray locking wedge from 86-pin connector to provide access to release the DT Pins.Note: Circuit U937 to be removed from pin location number 24 and transferred to pin location 73.Note: Cloth tape will need to be removed to the split in the harness main bundle.Note: The U937 wire can then be routed into the opposite branch to gain enough free length to make the connection.Note: The U939 wire removed from pin location 73 has adequate length to be loaded into location 16.

Transfer and relocate the wires as detailed in Table 2.

Reinstall the locking wedge (B) when all wires have been transferred and relocated.

Illustration 7 g06613197

View of back of ECM connector with connector cover (D) removed

Apply cloth tape to both wire branches from the main bundle of wires up the branches to the harness strain relief strap location.

Illustration 8 g06613199

Connector cover (D) reinstalled with harness secured

(1) 3S-2093 Cable Strap

(D) Connector cover

Reinstall connector cover (D) and secure the harness branches using two cable straps (1).

Use caution when re-engaging the connector with the ECM.

Tighten allen head screw (A).Note: In certain cases, U937 may require lengthening to provide adequate strain relief when relocated in pin 73.Note: Refer to "Soldered Splice","Deutsch connector", or "Sealed Mechanical Splice" for the proper way to extend circuit U937.Soldered Splice

A soldered spliced can be made to extend the wire. Soldered connection will need to be insulated using an appropriately sized adhesive head shrink sleeve.

Illustration 9 g06613210

U937 removed

Remove U937 from ECM connector.

Cut pin off end of wire.

Strip wire 7.5 mm (0.30 inch).

Illustration 10 g06613213

Additional wire soldered to circuit U937

Solder to additional wire to extend U937 and install appropriate sized adhesive head shrink sleeve.

Install pin on end of U937.

Insert U937 into pin 73.

Refer to "Procedure to Change Connector Plug Assembly Pins" for the proper method to reinstall ECM connector.Deutsch connector

Table 3

Required Parts

Qty Part Number Part Name

1 115-8109 Wire Splice Note: The deutsch connector is a field serviceable alternative to permanent splices. It is made from the same high-quality silicone elastomer as used for the Deutsch connector seals and grommets. The splice body houses a contact retention system that secures a mated pair of contacts in a compact environmentally sealed unit. This splice can also be serviced with standard deutsch connector tools.

Illustration 11 g06613218

Deutsch connector section view

Illustration 12 g06613221

Deutsch connector splice installed

Illustration 13 g06613224

Sufficient strain relief for deutsch connector

Refer to "Procedure to Change Connector Plug Assembly Pins" for the proper method to reinstall ECM connectorSealed Mechanical Splice

Table 4

Required Parts

Qty Part Number Part Name

1 136-4877 Wire Splice Note: Sealed mechanical splices have head-shrinkable, environmentally sealed sleeves.

Illustration 14 g06613205

Sealed mechanical splice

Select appropriate splice size.

Strip wire 7.5 mm (0.3 inch).

Insert stripped wire into sealed mechanical splice.

Crimp sealed mechanical splice.

Apply heat to the crimped splice until tubing re-covers and adhesive flows.

Refer to "Procedure to Change Connector Plug Assembly Pins" for the proper method to reinstall ECM connector

Have questions with 101602-2510?

Group cross 101602-2510 ZEXEL

Hino

101602-2510

9 400 614 778

220203540A

INJECTION-PUMP ASSEMBLY

EL100

EL100