Information injection-pump assembly

BOSCH

F 01G 09U 039

f01g09u039

ZEXEL

101602-2381

1016022381

Rating:

Service parts 101602-2381 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-1580

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Cross reference number

BOSCH

F 01G 09U 039

f01g09u039

ZEXEL

101602-2381

1016022381

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.1

3.05

3.15

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.8

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

45.3

43.3

47.3

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

7.8+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

9

7.5

10.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

C

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

63

63

73

Fixing the lever

*

Rack limit

*

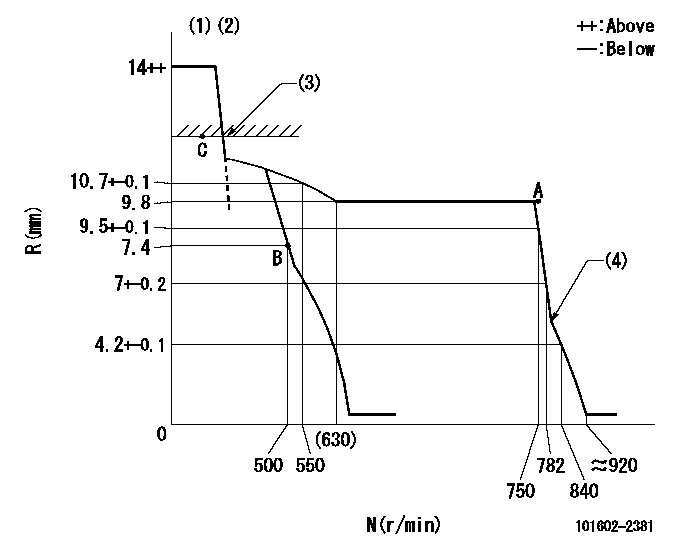

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

----------

K=9

----------

----------

K=9

----------

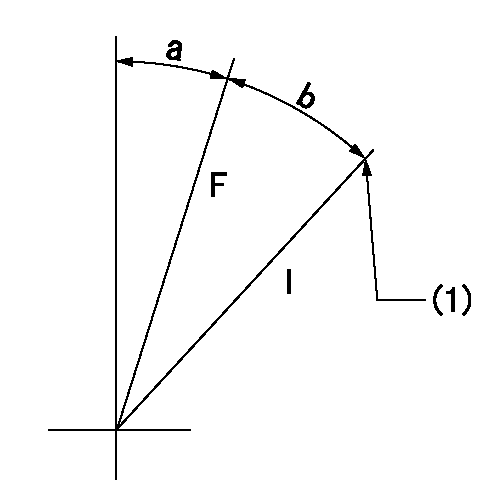

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=6deg+-5deg b=10deg+-5deg

----------

----------

a=6deg+-5deg b=10deg+-5deg

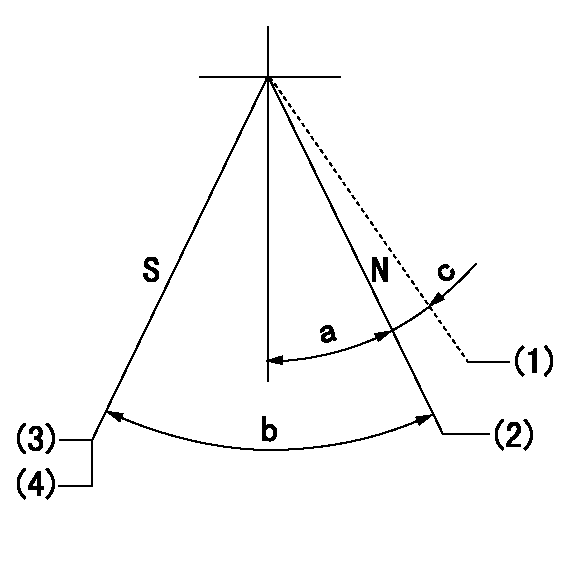

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Contacts normal side pin

(2)Distance from normal side pin = aa.

(3)Normal stop

(4)Rack position = bb or less, speed = cc

----------

aa=2.5+-0.5mm bb=6.9mm cc=0r/min

----------

a=27deg+-5deg b=53deg+-5deg c=(6deg)

----------

aa=2.5+-0.5mm bb=6.9mm cc=0r/min

----------

a=27deg+-5deg b=53deg+-5deg c=(6deg)

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Illustration 1 g01573105

Typical example (1) Terminal strip (2) Engine oil filler (3) Engine oil cooler (4) Engine oil level gauge (dipstick) (5) Fuel priming pump (6) Expansion tank filler cap (7) Expansion tank (8) Heat exchanger (9) Water pump (jacket water) (10) Engine oil filter (11) Fuel filter

Illustration 2 g01967833

Typical example (12) Filter change indicator (13) Aftercooler (14) Aftercooler condensate drain valve (15) Air cleaner (16) Air filter restriction indicator (17) Sea water pump (18) Fuel transfer pump (19) Filter for crankcase ventilation system (20) Electronic control module (ECM)Starting The Engine

The engine's Electronic Control Module (ECM) will automatically provide the correct amount of fuel in order to start the engine. Do not hold the throttle down while the engine is cranking. If the engine fails to start in 30 seconds, release the starting switch. Allow the starting motor to cool for two minutes before the starting motor is used again.

Excessive ether (starting fluid) can cause piston and ring damage. Use ether for cold weather starting purposes only.

Cold Mode Operation

The ECM will set cold mode when the coolant temperature is below 18 °C (64 °F).When the cold start strategy is activated, low idle rpm will be increased to 1000 rpm and engine power will be limited.Cold mode will be deactivated when the coolant temperature reaches 18 °C (64 °F).

Coolant temperature reaches 18 °C (64 °F).

The engine has been running for fourteen minutes.Cold mode varies the amount of fuel that is injected for white smoke cleanup. Cold mode also varies the timing for white smoke cleanup. The engine operating temperature is usually reached before the walk-around inspection is completed.After cold mode is completed, the engine should be operated at low speed until normal operating temperature is reached. The engine will reach normal operating temperature faster when the engine is operated at low speed and low power demand.Customer Specified Parameters

The engine is capable of being programmed for several customer specified parameters. For a brief explanation of each of the customer specified parameters, see the Operation and Maintenance Manual.