Information injection-pump assembly

BOSCH

F 019 Z10 825

f019z10825

ZEXEL

101602-2380

1016022380

HINO

220203260A

220203260a

Rating:

Service parts 101602-2380 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

236003620A

12.

Open Pre:MPa(Kqf/cm2)

21.6(220)

15.

NOZZLE SET

Cross reference number

BOSCH

F 019 Z10 825

f019z10825

ZEXEL

101602-2380

1016022380

HINO

220203260A

220203260a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.1

3.05

3.15

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.2

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

58.1

56.1

60.1

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

8+-0.5

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

8.5

7

10

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

13+-0.5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

72

72

82

Fixing the lever

*

Rack limit

*

Test data Ex:

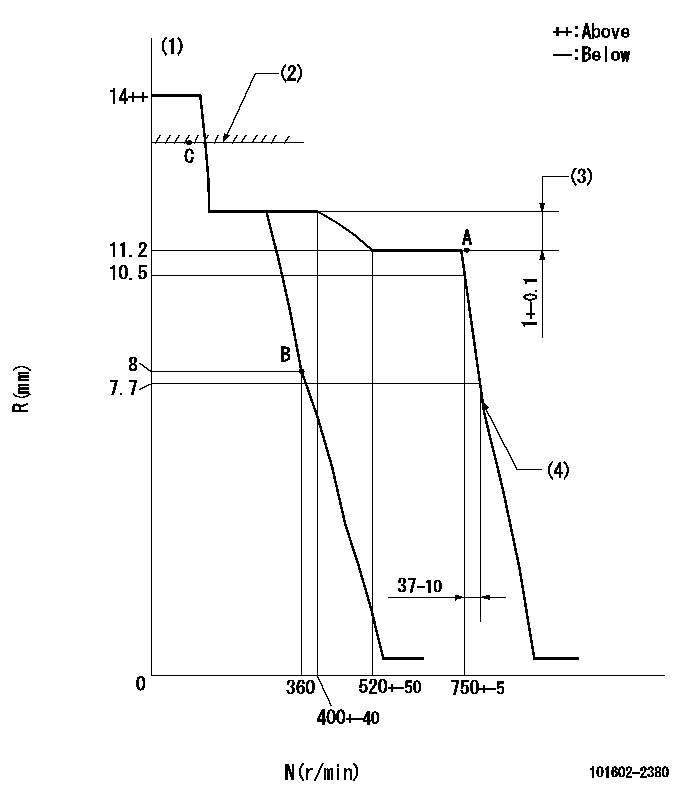

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT

(3)Rack difference between N = N1 and N = N2

(4)Idle sub spring setting: L1.

----------

K=4 N1=750r/min N2=350r/min L1=7.1-0.5mm

----------

----------

K=4 N1=750r/min N2=350r/min L1=7.1-0.5mm

----------

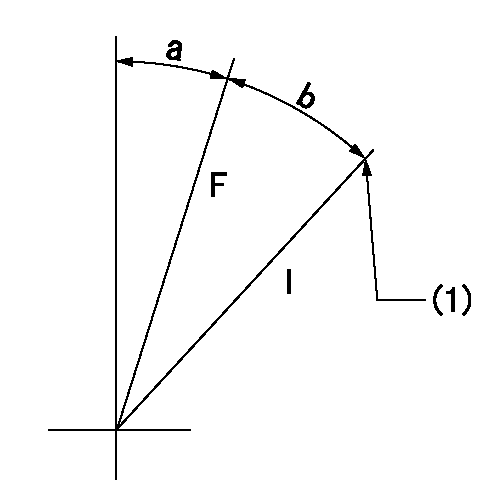

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(7deg)+-5deg b=(13deg)+-5deg

----------

----------

a=(7deg)+-5deg b=(13deg)+-5deg

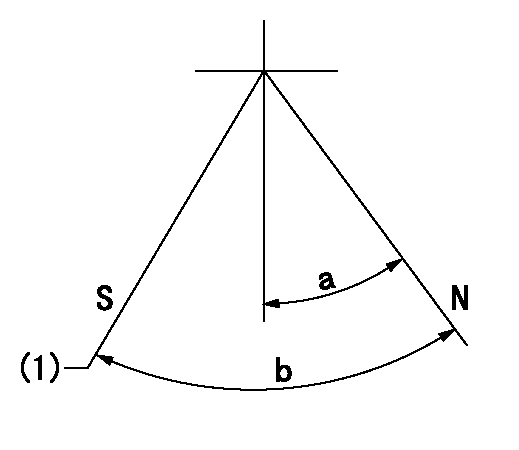

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)At shipping

----------

----------

a=27deg+-5deg b=53deg+-5deg

----------

----------

a=27deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Illustration 1 g01096972

Hand priming pump (1) Air purge screw (2) Fuel pressure regulating valve

Open air purge screw (1) for the fuel filter by three full turns. Do not remove the air purge screw.

Do not crank the engine continuously for more than 30 seconds. Allow the starting motor to cool for two minutes before cranking the engine again.

Start the engine. The engine should start and the engine should run smoothly. If the engine does not start after 30 seconds, allow the starting motor to cool for two minutes before attempting to start the engine again.Note: You may use the hand priming pump for the fuel filter (if equipped) instead of starting the engine and running the engine.

While the engine is running, observe air purge screw (1). When a small drop of fuel appears at the threads of the air purge screw, close and tighten air purge screw (1) .Note: There may be a noticeable change in the sound of the running engine when the air purge screw is tightened. The change in the sound of the engine is normal.Note: Failure to tighten all fittings could result in serious fuel leaks.

Clean any residual fuel from the engine components.The Engine Has Been Run Out of Fuel

Use a suitable container to catch any fuel that might spill. Clean up any spilled fuel immediately.

Do not allow dirt to enter the fuel system. Thoroughly clean the area around a fuel system component that will be