Information injection-pump assembly

BOSCH

F 019 Z10 824

f019z10824

ZEXEL

101602-2192

1016022192

HINO

220202582A

220202582a

Rating:

Service parts 101602-2192 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

236003620A

12.

Open Pre:MPa(Kqf/cm2)

21.6(220)

15.

NOZZLE SET

Cross reference number

BOSCH

F 019 Z10 824

f019z10824

ZEXEL

101602-2192

1016022192

HINO

220202582A

220202582a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.1

3.05

3.15

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.2

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

58.1

56.1

60.1

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

8+-0.5

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

8.5

7

10

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

13+-0.5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

72

72

82

Fixing the lever

*

Rack limit

*

Test data Ex:

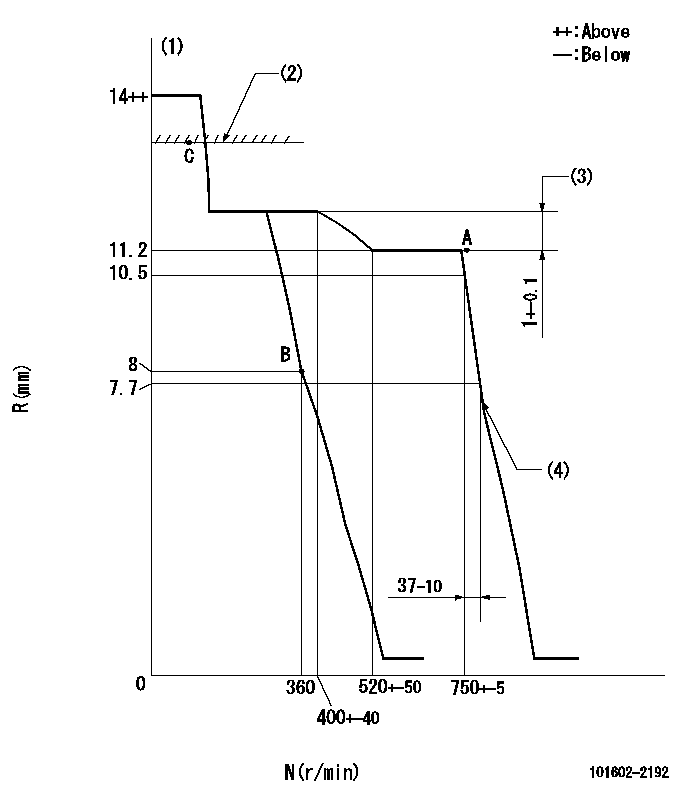

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT

(3)Rack difference between N = N1 and N = N2

(4)Idle sub spring setting: L1.

----------

K=4 N1=750r/min N2=350r/min L1=7.1-0.5mm

----------

----------

K=4 N1=750r/min N2=350r/min L1=7.1-0.5mm

----------

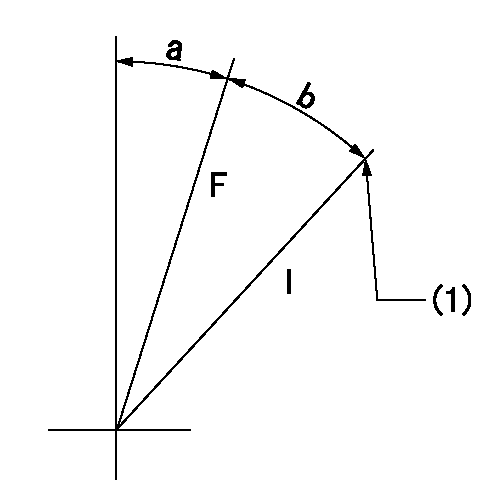

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(7deg)+-5deg b=(13deg)+-5deg

----------

----------

a=(7deg)+-5deg b=(13deg)+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=27deg+-5deg b=53deg+-5deg

----------

----------

a=27deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Illustration 1 g01491433

Measuring the outer diameter of the center section of the DPF

Illustration 2 g01756814

DPF flange designs (B) Standard flange (C) Submerged flange

Measure the outer diameter of the center section of the DPF. Illustration 1 shows the outer diameter of the center section of the DPF. Use Table 2 to locate the appropriate cone and the proper adapters for your application.Note: These adapters are part of the 319-2189 Diesel Particulate Filter Cleaner Gp .

Table 2

Model and Description for the DPF Outer Diameter of the Center Section of the DPF

"A" Large Cone

319-1836 Medium Cone

319-1835 Small Cone

319-2192 Upper Adapter for Mass Transit Buses (MTB)

319-2192 Lower Adapter

319-1838 Lower Adapter

319-1839 Gasket Part Number

(mm) (inches)

9.5 x 14 Submerged 253.1 10 X X 293-6156

9.5 x 14 Standard 279.3 11 X X 279-3259

11.25 x 14 Submerged 279.3 11 X X 279-3259

264-1556 Filter Module As MTB 318.2 12.5 X X X 247-1899

11.25 x 14

MTB Standard 321.1 12.6 X X 279-1081

13 x 15 or 13 x 17 Submerged 342.8 13.5 X X 279-2123

12 x 15 342.8 13.5 X X 279-2123

13 x 15 or 13 x 17Standard 368.2 14.5 X X 278-5711 Note: All the pressure ports and the thermocouple ports on the DPF must be plugged before cleaning.

Illustration 3 g01491993

Plug any other open ports on the DPF.

Install a 2F-2990 Seal Plug or a 102-9379 Plug in all the open ports on the DPF.

Assemble the DPF. Refer to the engine Disassembly and Assembly Manual, "Diesel Particulate Filter - Assemble" for the proper procedure to assemble the DPF.

Reinstall the DPF onto the vehicle.Ash Service Reset

The engine ash model must be reset whenever the filter is cleaned or replaced. This resets the DPF volume back to the "Clean State". The resetting will allow the regeneration of the DPF to function properly.

Use Cat ET to access the configuration parameters. In the "System Settings" group of parameters, highlight the" Diesel Particulate Filter Ash Service Reset". Refer to Illustration 4 for the location of the " Diesel Particulate Filter Ash Service Reset". The value of the parameter should be "Not Reset".

Click the "Change" button at the bottom of the screen. The change will require the Factory Passwords to be reset. Enter "Reason code 67".

Enter the