Information injection-pump assembly

BOSCH

9 400 614 754

9400614754

ZEXEL

101602-2153

1016022153

HINO

220202013A

220202013a

Rating:

Service parts 101602-2153 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-1593A

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 614 754

9400614754

ZEXEL

101602-2153

1016022153

HINO

220202013A

220202013a

Zexel num

Bosch num

Firm num

Name

101602-2153

9 400 614 754

220202013A HINO

INJECTION-PUMP ASSEMBLY

W06D * K

W06D * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.1

3.05

3.15

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

8.3

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

34.6

31.6

37.6

Max. variation between cylinders

%

0

-4

4

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

9.4

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

46.4

44.4

48.4

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

8+-0.5

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

8.2

6.7

9.7

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

95

95

105

Fixing the lever

*

Rack limit

*

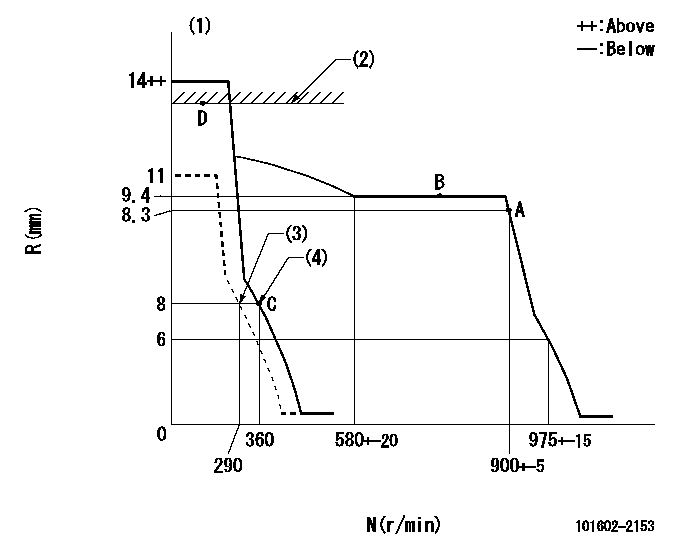

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT

(3)Set idle sub-spring

(4)Main spring setting

----------

K=5

----------

----------

K=5

----------

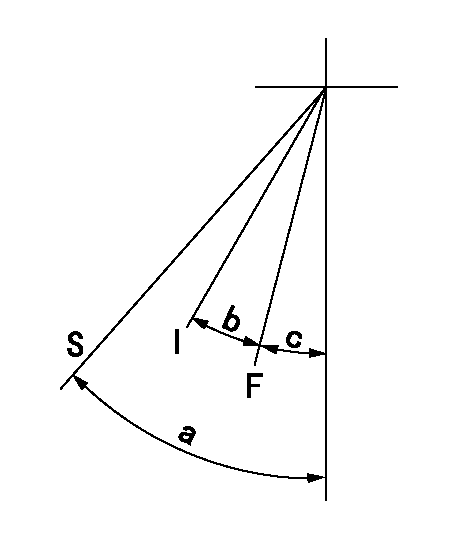

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=32deg+-3deg b=(14deg)+-5deg c=(5deg)+-5deg

----------

----------

a=32deg+-3deg b=(14deg)+-5deg c=(5deg)+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Determine the fuel rail pressure and the injector test engine speed (where the peak pressure was selected). Typically, pressure will start building after 2 to 5 seconds and then there should be sampling for 5 more seconds. Illustration 7 shows an example of selecting the peak pressure and corresponding speed.

Calculate the speed change of the injector test as follows:Injector test speed change equals injector test engine speed minus pump test engine speed.

Determine injector pressure correction using the injector test speed change and Table 5. This will correct for pressure change as speed changes.

Table 5

Injector Pressure Correction Based on Speed Change

Engine speed change (rpm) 0-5 6-10 11-15 16-20 21-25 26-30 31-35

Six-cylinder pressure correction 283 kPa (41 psi) 896 kPa (130 psi) 1455 kPa (211 psi) 2013 kPa (292 psi) 2572 kPa (373 psi) 3130 kPa (454 psi) 3689 kPa (535 psi)

Four-cylinder pressure correction 159 kPa (23 psi) 510 kPa (74 psi) 834 kPa (121 psi) 1151 kPa (167 psi) 1469 kPa (213 psi) 1793 kPa (260 psi) 2110 kPa (306 psi)

If the injector test engine speed is lower than pump test engine speed, then correct the injector pressure by adding the correction as follows:Injector corrected pressure equals injector test pressure plus injector pressure correction.

If the injector test engine speed is higher than pump test engine speed (as can happen when a battery booster is used), then correct the injector test pressure by subtracting the pressure correction as follows:Injector corrected pressure equals injector test pressure minus injector pressure correction.

Calculate injector leakage ratio as follows:Injector leakage ratio equals injector corrected pressure divided by pump test rail pressure.If the Injector leakage ratio is less than 0.85, the injector must be replaced, if the injector leakage is greater than 0.85 the injector is within the required parameters.Remove the fuel line. Replace the cap on the fuel manifold (rail) and injector.

Proceed to the next injector to be checked. Repeat Step 1 through Step 8 for the remaining electronic unit injectors to be tested.

Remove components of 362-9754 Test Kit from the engine. Replace any fuel injection lines that were removed during the procedures. Refer to Disassembly and Assembly, Fuel Injection Lines - Install for the correct procedure.

Reconnect the electronic unit injector harness connectors.Test Kit Data Sheet

Table 6

Fuel Injection Pump Tests Pump Test Rail Pressure Pump Test Engine Speed Minimum Cranking Pressure (MCP) Service

From Pump Test Datalog From Pump

Have questions with 101602-2153?

Group cross 101602-2153 ZEXEL

Hino

101602-2153

9 400 614 754

220202013A

INJECTION-PUMP ASSEMBLY

W06D

W06D