Information injection-pump assembly

ZEXEL

101602-2080

1016022080

HINO

220201940A

220201940a

Rating:

Cross reference number

ZEXEL

101602-2080

1016022080

HINO

220201940A

220201940a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0620

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.85

4.8

4.9

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

7.9

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

80.5

78.9

82.1

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

4.2+-0.5

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

9.5

8

11

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Test data Ex:

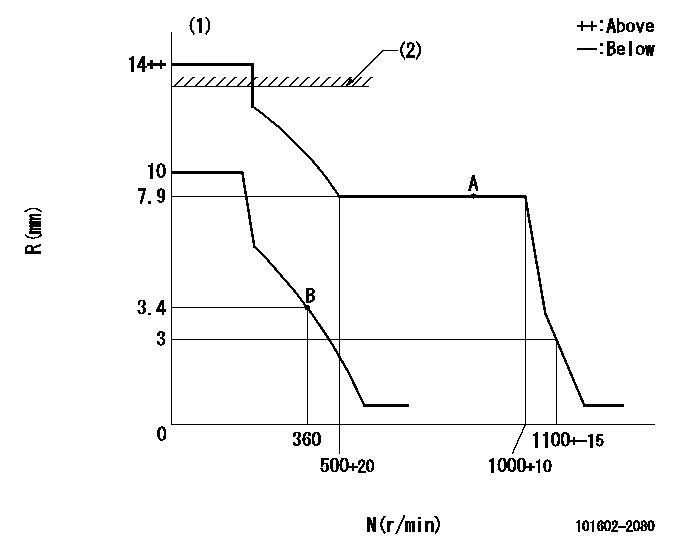

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT: RAL

----------

K=8 RAL=14+0.2mm

----------

----------

K=8 RAL=14+0.2mm

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=5.5deg+-5deg b=28deg+-5deg

----------

----------

a=5.5deg+-5deg b=28deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=27deg+-5deg b=53deg+-5deg

----------

----------

a=27deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Clean any machining debris that may be on the inside of the flywheel housing.Ensure that the debris guard is clean. A clean guard will ensure that no machining debris falls into the engine when the debris guard is removed.

Remove the debris guard from the inside of the flywheel housing.Install the Pipe Adapters and Sensors

Use 12 5P-2424 Bolts and 118-0275 Washers in order to install wheel (1) onto the cam gear.

Illustration 24 g01323683

(K) Installation guide for the pipe adapters

Illustration 25 g01323672

(1) 284-8910 Wheel

Install the installation guide for the pipe adapters.The installation guide must be installed on the evenly spaced teeth of wheel (1). Refer to Illustration 25.

Illustration 26 g01323669

(2) Fabricated pipe adapters

Install the top and the bottom pipe adapters (2) that were fabricated from the design in Illustration 6.

Use 7M-7456 Bearing Mount Compound to coat the outside of pipe adapter (2) .

Ensure that the adapter is properly aligned with the machined hole.

Illustration 27 g01323703

(L) Bushing driver (2) Pipe adapter

Illustration 28 g01323665

Pipe adapter (2) in contact with installation guide (K)

Use bushing driver (L) to install pipe adapters (2) .Continue installing the pipe adapters until the adapters contact the installation guide. The guide will not wiggle when the adapters are properly installed. Refer to Illustrations 27 and 28.

Remove the installation guide.

Illustration 29 g01324920

Correct alignment of the center pole of the speed sensor (3) Center pole of the speed sensor

Inspect the hole in pipe adapters (2) .The tooth of wheel (1) must be in the center of the hole in the pipe adapter. In order to ensure that the speed sensor will operate correctly, the center of the speed sensor must align with a tooth on wheel (1). Refer to Illustration 29 for an example of the correct alignment.

Illustration 30 g01323661

183-8597 Speed Sensor Gp

Illustration 31 g01323666

Speed sensors (5) Primary speed sensor (6) Secondary speed sensor

Install 3K-0360 O-Ring Seals with primary speed sensor (5) and secondary speed sensor (6) . 183-8597 Speed Sensor Gp Torque ... 37 4 N m (27 3 lb ft) Clearance between tip of sensor and the wheel ... 0.750 mm to 2.000 mm (0.0295 inch to 0.0787 inch)Note: Note the position of extra tooth (7) in relation to primary speed sensor (5) .Note: The 284-8909 Camshaft Gear may need repositioned in order to adjust the position of wheel (1).

Illustration 32 g01323706

Typical example of wheel (1) in standard rotation (7) Extra tooth

Illustration 33 g01323668

Typical example of wheel (1) in reverse rotation

Adjust the 284-8910 Wheel .

Align the first tooth after extra tooth (7) with the center of the primary speed sensor.Refer to Illustration 32.

Torque the bolts to 120 N m (89 lb ft).

Recheck the alignment of the first tooth after extra tooth (7) and the primary speed sensor.

Install the 240-9736 Cylinder Block Cover Gp .

Use 0S-1594 Bolts and 3V-3308 Hard Washers in order to install the two 4B-3140 Covers and the 1W-1960 Gaskets onto the front housing of the engine.

Use 3B-1915 Bolts and 3V-3308 Hard Washers in order to install the 7E-5420 Cover and