Information injection-pump assembly

ZEXEL

101602-2060

1016022060

HINO

220201530A

220201530a

Rating:

Cross reference number

ZEXEL

101602-2060

1016022060

HINO

220201530A

220201530a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0620

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.85

4.8

4.9

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

8.6

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

91

89.4

92.6

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

4.3+-0.5

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

9.5

8

11

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Test data Ex:

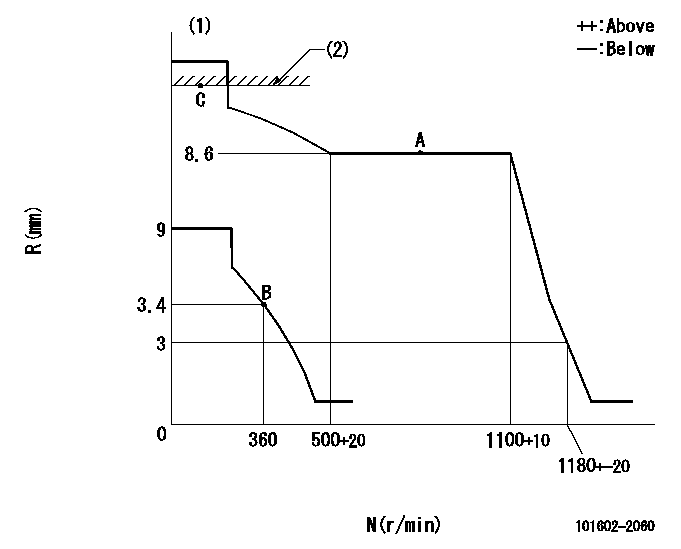

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT: RAL

----------

K=11 RAL=14+0.2mm

----------

----------

K=11 RAL=14+0.2mm

----------

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=12deg+-5deg b=32deg+-3deg c=35deg+-5deg

----------

----------

a=12deg+-5deg b=32deg+-3deg c=35deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=27eg+-5deg b=53deg+-5deg

----------

----------

a=27eg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Procedure

Illustration 1 g06220548

(1) TC Mark (Flywheel Housing)

(2) TC Mark (Flywheel)

Remove valve cover, and injector and rocker arm. Bring the piston of cylinder 4 to TDC.

Illustration 2 g06220554

(3) Dial Gauge

(4) Valve

(5) O-ring

Remove the #4 exhaust valve bridge arm and valve spring. Insert a small O-ring (5) so the valve does not fall into the cylinder.

Set dial gauge (3) on the tip of the valve (4).

Illustration 3 g06220569

(6) Tri - Square

(7) Flywheel Housing

(8) Flywheel

Illustration 4 g06220573

(7) Flywheel Housing

(8) Flywheel

(9) Reference Line

Turn the flywheel counterclockwise and measure the position where the tip of the valve is the highest.

Stop the flywheel at the position where the tip of the valve is the highest. Put a tri - square (6) on the flywheel housing (7) and the flywheel (8) and draw a reference line (9).Do not drop the valve (4) into the cylinder. When measuring the highest position of the tip of the valve, do not rotate the flywheel clockwise. If you go past the highest point of the valve, back up the flywheel slightly and measure the highest point of the valve. The reference line (9) indicates the TDC of the crankshaft.

Illustration 5 g06220579

Rotation Sensor Signal Interface Unit

Application: Use for reading rotation sensor signal.

(1) 9V Battery

(2) Switch

(3) 3-Terminal Regulator

(4) LED

(5) Clip (Red)

(6) Clip (Black)

(A) for Panasonic

(B) for Denso

(C) for Bosch cam angle

(D) for Bosch crank angle

((E)) Connector Side

(a) +9 V

(b) Signal

(c) GND

(d) +5 V

(e) Signal

(f) GND

Schematic to build Rotation Sensor Signal Interface.

Illustration 6 g06220581

(10) Rotation Sensor Signal Interface (Tool not available. Schematic to build tool available. Refer to Step 6.

(11) Tester

Illustration 7 g06220587

(12) Ground Terminal

(13) Output Terminal

(14) Crankshaft Position Sensor

Connect a connector of the rotation sensor signal interface unit (10) to the crankshaft position sensor (14). Connect each clip of the rotation sensor signal interface unit (10) to the same test lead color of the tester (11). Switch on the rotation sensor signal interface unit (10).

Illustration 8 g06220590

(15) Pulsar Gear

(16) 14th Tooth

(17) Missing Teeth

Turn the flywheel and make sure that the voltage of the crankshaft position sensor goes from 0→ 5 V or 5 → 0 V.

Rotate the flywheel and align the crankshaft position sensor to the part of the pulsar gear (15) that is missing teeth (17). The 14th tooth (16) from the missing teeth is standard.

Slowly turn flywheel counterclockwise and stop flywheel at the point where needle of the tester changes momentarily from 0 → 5 V, the 14th tooth.That point is where the crankshaft position sensor detects TDC.

Illustration 9 g06220608

(18) Crankshaft TDC

(19) Detection Point of Crankshaft Position Sensor TDC

Illustration 10 g06220612

(20) Interval

Set the tri - square (6) on the reference line (9) on the flywheel housing side and mark the detection point of crankshaft position sensor TDC (19) on the flywheel.

Measure the interval (20) between the crankshaft TDC (18) and the detection point of the crankshaft position sensor TDC (19).

Calculation of fuel injection timing correction 1.0 mm (0.039 in.): 0.321°.Corrected Angle = 0.321° X actual interval

Overwrite the injection timing correction value on the engine ecm registration website refer to REHS9707, "Registering Diesel Particulate Filter (DPF), Diesel Oxidation Catalyst (DOC),

Illustration 1 g06220548

(1) TC Mark (Flywheel Housing)

(2) TC Mark (Flywheel)

Remove valve cover, and injector and rocker arm. Bring the piston of cylinder 4 to TDC.

Illustration 2 g06220554

(3) Dial Gauge

(4) Valve

(5) O-ring

Remove the #4 exhaust valve bridge arm and valve spring. Insert a small O-ring (5) so the valve does not fall into the cylinder.

Set dial gauge (3) on the tip of the valve (4).

Illustration 3 g06220569

(6) Tri - Square

(7) Flywheel Housing

(8) Flywheel

Illustration 4 g06220573

(7) Flywheel Housing

(8) Flywheel

(9) Reference Line

Turn the flywheel counterclockwise and measure the position where the tip of the valve is the highest.

Stop the flywheel at the position where the tip of the valve is the highest. Put a tri - square (6) on the flywheel housing (7) and the flywheel (8) and draw a reference line (9).Do not drop the valve (4) into the cylinder. When measuring the highest position of the tip of the valve, do not rotate the flywheel clockwise. If you go past the highest point of the valve, back up the flywheel slightly and measure the highest point of the valve. The reference line (9) indicates the TDC of the crankshaft.

Illustration 5 g06220579

Rotation Sensor Signal Interface Unit

Application: Use for reading rotation sensor signal.

(1) 9V Battery

(2) Switch

(3) 3-Terminal Regulator

(4) LED

(5) Clip (Red)

(6) Clip (Black)

(A) for Panasonic

(B) for Denso

(C) for Bosch cam angle

(D) for Bosch crank angle

((E)) Connector Side

(a) +9 V

(b) Signal

(c) GND

(d) +5 V

(e) Signal

(f) GND

Schematic to build Rotation Sensor Signal Interface.

Illustration 6 g06220581

(10) Rotation Sensor Signal Interface (Tool not available. Schematic to build tool available. Refer to Step 6.

(11) Tester

Illustration 7 g06220587

(12) Ground Terminal

(13) Output Terminal

(14) Crankshaft Position Sensor

Connect a connector of the rotation sensor signal interface unit (10) to the crankshaft position sensor (14). Connect each clip of the rotation sensor signal interface unit (10) to the same test lead color of the tester (11). Switch on the rotation sensor signal interface unit (10).

Illustration 8 g06220590

(15) Pulsar Gear

(16) 14th Tooth

(17) Missing Teeth

Turn the flywheel and make sure that the voltage of the crankshaft position sensor goes from 0→ 5 V or 5 → 0 V.

Rotate the flywheel and align the crankshaft position sensor to the part of the pulsar gear (15) that is missing teeth (17). The 14th tooth (16) from the missing teeth is standard.

Slowly turn flywheel counterclockwise and stop flywheel at the point where needle of the tester changes momentarily from 0 → 5 V, the 14th tooth.That point is where the crankshaft position sensor detects TDC.

Illustration 9 g06220608

(18) Crankshaft TDC

(19) Detection Point of Crankshaft Position Sensor TDC

Illustration 10 g06220612

(20) Interval

Set the tri - square (6) on the reference line (9) on the flywheel housing side and mark the detection point of crankshaft position sensor TDC (19) on the flywheel.

Measure the interval (20) between the crankshaft TDC (18) and the detection point of the crankshaft position sensor TDC (19).

Calculation of fuel injection timing correction 1.0 mm (0.039 in.): 0.321°.Corrected Angle = 0.321° X actual interval

Overwrite the injection timing correction value on the engine ecm registration website refer to REHS9707, "Registering Diesel Particulate Filter (DPF), Diesel Oxidation Catalyst (DOC),