Information injection-pump assembly

ZEXEL

101602-2030

1016022030

HINO

220201400A

220201400a

Rating:

Cross reference number

ZEXEL

101602-2030

1016022030

HINO

220201400A

220201400a

Zexel num

Bosch num

Firm num

Name

101602-2030

220201400A HINO

INJECTION-PUMP ASSEMBLY

EL100 * K

EL100 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134428-0620

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.85

4.8

4.9

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

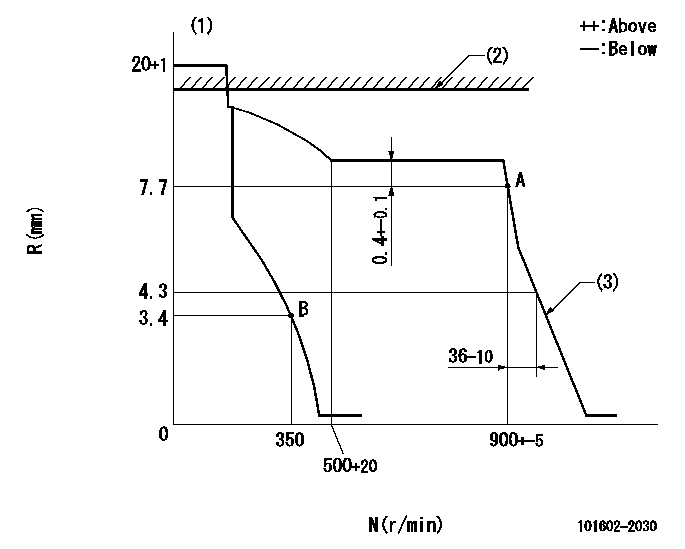

Injection quantity adjustment

Adjusting point

A

Rack position

7.7

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

82

80.4

83.6

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

R1

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

9.5

8

11

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT: RAL

(3)Idle sub spring setting: L1.

----------

K=18 RAL=13.9+0.2mm L1=4.5+-0.2mm

----------

----------

K=18 RAL=13.9+0.2mm L1=4.5+-0.2mm

----------

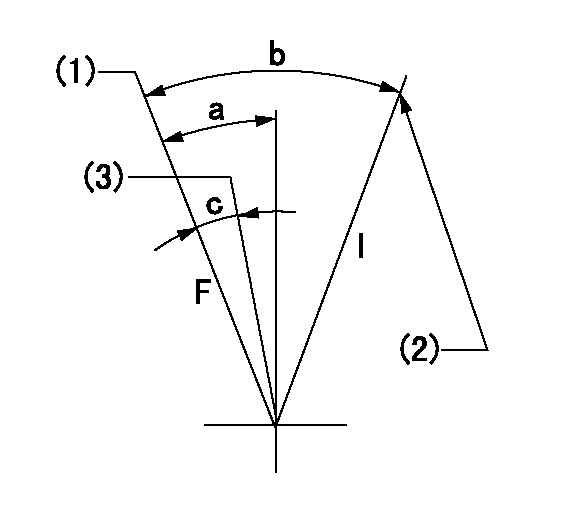

Speed control lever angle

F:Full speed

I:Idle

(1)Pump speed = aa

(2)Stopper bolt setting

(3)Pump speed = bb

----------

aa=900r/min bb=750r/min

----------

a=9deg+-5deg b=28deg+-5deg c=7deg+-5deg

----------

aa=900r/min bb=750r/min

----------

a=9deg+-5deg b=28deg+-5deg c=7deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=27deg+-5deg b=53deg+-5deg

----------

----------

a=27deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Table 15

CDL Diagnostic

Sensor Description DTC CID FMI Harness Pin Number Harness Connector

Fuel Supply Flow Rotor Speed Sensor 1 4515 10 and 14 J1-6 A-C2

Fuel Supply Flow Rotor Speed Sensor 2 4516 8 J1-52 A-C3

Fuel Return Flow Rotor Speed Sensor 1 4517 10 and 14 J1-61 C-C2

Fuel Return Flow Rotor Speed Sensor 2 4518 8 J1-63 C-C3 If the fuel volume speed sensor detects an abnormal rate of change, a diagnostic of FMI 10, "Abnormal Rate of Change", will be reported on the SAE J1939 data link and the CDL data link for the errant sensor. An "Abnormal Rate of Change" will be detected when the measured frequency is greater than the maximum flow rate for which the transducer is rated.If the fuel volume speed sensor detects an abnormal frequency, pulse width or period, a diagnostic of FMI 8, "Abnormal Frequency, Pulse Width or Period", will be reported on the SAE J1939 data link and the CDL data link for the errant sensor. This indicates a loose or pinched wire or an errant speed sensor. An abnormal frequency, pulse width, or period will be detected if the frequency reading indicates that the transducer has been installed backwards.If the fuel volume speed sensor outputs a flow rate of 160 pps or more, a diagnostic with FMI 14 will be reported on the SAE J1939 data link and the CDL. This indicates that the flow rate through the transducer is approaching the maximum flow rate.Temperature Sensor Diagnostic Indicators

If a temperature sensor fails, the ECM raises a diagnostic message and sends it on the main SAE J1939 data link and the CDL bus.

Table 16

Sensor Description SAE J1939 SPN CDL DTC CID Harness Pin Number Harness Connector

Fuel Flow Supply Temperature Sensor 2775 4519 J1-36 A-C4

Fuel Flow Supply Temperature Sensor 2776 1929 J1-37 C-C4 If a diagnostic of FMI 3, Voltage Above Normal, is reported on the SAE J1939 data link or the CDL data link for the errant sensor, this indicates possible short to battery indicating a broken wire or defective sensor.If a diagnostic of FMI 4, Voltage Below Normal, is reported on the SAE J1939 data link or the CDL data link for the errant sensor, this indicates possible short to ground indicating a pinched wire or defective sensor.Data Retention

The system is designed to monitor the fuel consumed by the engine, irrespective of time. If either transducer is replaced, the ECM will not reset the fuel volume values.Replacing Failed Parts

The fuel volume transducer is a precision device. If the transducer experiences a failure in one of the sensors, the specific sensor can be replaced without impacting the calibration of the device.Replacement part numbers are as follows:

Table 17

Replacement Parts

Part Description Low Flow Rate System High Flow Rate System

Speed Sensor 384-3887 Speed Sensor Gp 384-3887 Speed Sensor Gp

Speed Sensor O-ring

Temperature Sensor 191-6587 Temperature Sensor Gp 238-0112 Temperature Sensor Gp

Temperature Sensor O-ring 214-7568 O-Ring Seal 214-7568 O-Ring Seal

Transducer 434-5030 Flow Meter Gp 434-5040 Flow Meter Gp Replacing

Have questions with 101602-2030?

Group cross 101602-2030 ZEXEL

Hino

101602-2030

220201400A

INJECTION-PUMP ASSEMBLY

EL100

EL100