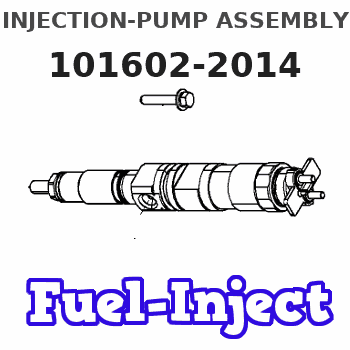

Information injection-pump assembly

BOSCH

9 400 610 245

9400610245

ZEXEL

101602-2014

1016022014

HINO

220201168A

220201168a

Rating:

Service parts 101602-2014 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-1171

12.

Open Pre:MPa(Kqf/cm2)

18.1{185}

15.

NOZZLE SET

Cross reference number

Zexel num

Bosch num

Firm num

Name

101602-2014

9 400 610 245

220201168A HINO

INJECTION-PUMP ASSEMBLY

EL100 * K 14BF PE6AD PE

EL100 * K 14BF PE6AD PE

Information:

Introduction

Procedure to prevent injector Plunger Spring failure due to inadequate fuel system priming.

The low-pressure fuel system must be primed after injector replacement or other repair to the low-pressure fuel system circuit which may allow air to enter the system.

Inadequate priming can result in air being present in the low-pressure fuel system and inside the injectors.

Attempting to start the engine without adequate priming may result in an early hour failure of the injector plunger spring.

Follow the procedure below to prevent injector failure due to inadequate priming.

DO NOT START THE ENGINE WITHOUT PRIMING THE FUEL SYSTEM

Illustration 1 g03735591

Damaged plunger spring due to improper fuel system primingFuel System Priming Procedure:

Disconnect the injector harness at the valve cover.

Use the hand primer to fill the fuel system. Pump until the hand primer becomes too hard to depress by hand.

Crank the engine 3 times for 15 seconds each. Reapply the hand primer after each cranking cycle.

Once the hand primer remains hard to depress after the 15 second crank, reconnect the injector harness and start the engine.

Clear any related fault codes (ET) that were logged while cranking the engine with the injector harness disconnected.

Illustration 2 g03736011

Procedure to prevent injector Plunger Spring failure due to inadequate fuel system priming.

The low-pressure fuel system must be primed after injector replacement or other repair to the low-pressure fuel system circuit which may allow air to enter the system.

Inadequate priming can result in air being present in the low-pressure fuel system and inside the injectors.

Attempting to start the engine without adequate priming may result in an early hour failure of the injector plunger spring.

Follow the procedure below to prevent injector failure due to inadequate priming.

DO NOT START THE ENGINE WITHOUT PRIMING THE FUEL SYSTEM

Illustration 1 g03735591

Damaged plunger spring due to improper fuel system primingFuel System Priming Procedure:

Disconnect the injector harness at the valve cover.

Use the hand primer to fill the fuel system. Pump until the hand primer becomes too hard to depress by hand.

Crank the engine 3 times for 15 seconds each. Reapply the hand primer after each cranking cycle.

Once the hand primer remains hard to depress after the 15 second crank, reconnect the injector harness and start the engine.

Clear any related fault codes (ET) that were logged while cranking the engine with the injector harness disconnected.

Illustration 2 g03736011

Have questions with 101602-2014?

Group cross 101602-2014 ZEXEL

Hino

101602-2014

9 400 610 245

220201168A

INJECTION-PUMP ASSEMBLY

EL100

EL100