Information injection-pump assembly

ZEXEL

101602-1460

1016021460

Rating:

Service parts 101602-1460 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME078365

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}

15.

NOZZLE SET

Include in #1:

101602-1460

as INJECTION-PUMP ASSEMBLY

Include in #2:

105866-7121

as _

Cross reference number

ZEXEL

101602-1460

1016021460

Zexel num

Bosch num

Firm num

Name

101602-1460

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.5

4.45

4.55

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.4

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

118.5

115

122

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Boost pressure

kPa

53.3

53.3

Boost pressure

mmHg

400

400

Injection quantity adjustment_02

Adjusting point

-

Rack position

6.4+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

10.6

9.1

12.1

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Boost compensator adjustment

Pump speed

r/min

650

650

650

Rack position

R1-0.75

Boost pressure

kPa

28

25.3

30.7

Boost pressure

mmHg

210

190

230

Boost compensator adjustment_02

Pump speed

r/min

650

650

650

Rack position

R1(9.4)

Boost pressure

kPa

40

33.3

46.7

Boost pressure

mmHg

300

250

350

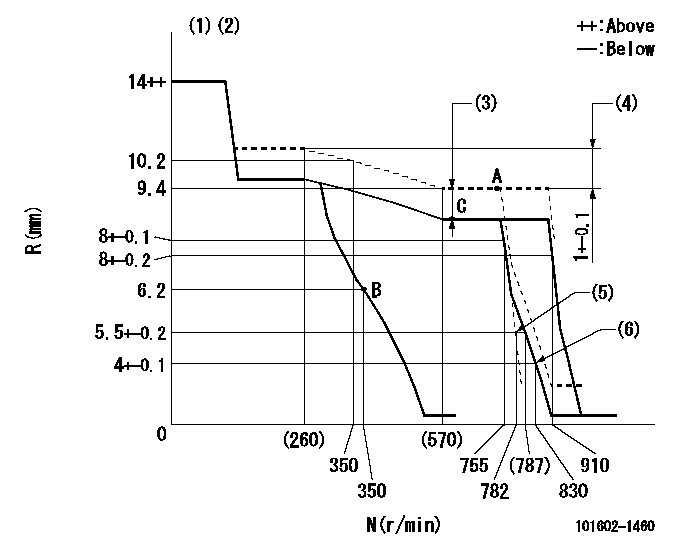

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

(4)Rack difference between N = N1 and N = N2

(5)Main spring setting

(6)Set idle sub-spring

----------

K=15 BCL=0.75+-0.1mm N1=750r/min N2=230r/min

----------

----------

K=15 BCL=0.75+-0.1mm N1=750r/min N2=230r/min

----------

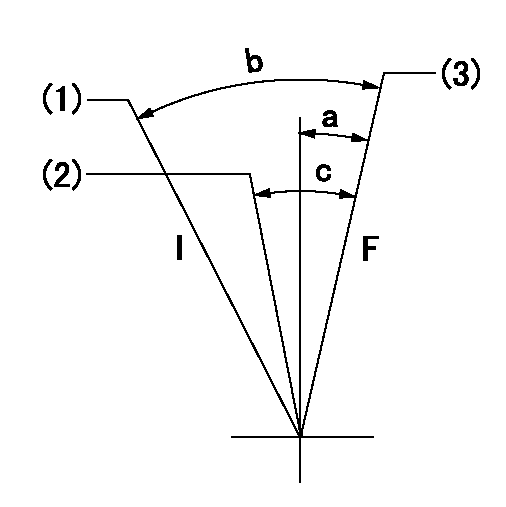

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)Pump speed = aa

(3)Pump speed = bb

----------

aa=755r/min bb=910r/min

----------

a=(1deg)+-5deg b=(20deg)+-5deg c=(6deg)+-5deg

----------

aa=755r/min bb=910r/min

----------

a=(1deg)+-5deg b=(20deg)+-5deg c=(6deg)+-5deg

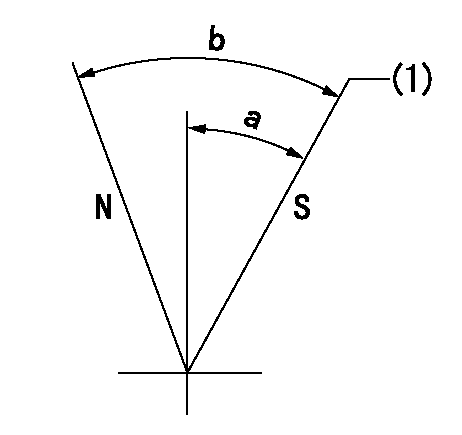

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa and rack position bb (to be sealed at delivery)

----------

aa=0r/min bb=1-0.5mm

----------

a=35deg+-5deg b=(55deg)

----------

aa=0r/min bb=1-0.5mm

----------

a=35deg+-5deg b=(55deg)

Timing setting

(1)Pump vertical direction

(2)Position of coupling's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=10deg

----------

a=(1deg)

----------

aa=10deg

----------

a=(1deg)

Information:

Do not use the same vacuum sampling pump for extracting oil samples that is used for extracting coolant samples.A small residue of either type sample may remain in the pump and may cause a false positive analysis for the sample being taken.Always use a separate pump for oil sampling and a separate pump for coolant sampling.Failure to do so may cause a false analysis which could lead to customer and dealer concerns.

New Systems, Refilled Systems, and Converted Systems

Perform an S O S coolant analysis (Level 2) at the following maintenance intervals.

Initial 500 service hours

Every Year or every 2000 hours, whichever comes firstPerform this analysis at the interval that occurs first for new systems, for refilled systems, or for converted systems that use Cat ELC (Extended Life Coolant) or use Cat DEAC (Diesel Engine Antifreeze/Coolant). This 500 hour check will also check for any residual cleaner that may have contaminated the system.Recommended Interval for S O S Services Coolant Sample

The following table contains the recommended sampling interval for all coolants that meet Cat EC-1 (Engine Coolant specification - 1). This is also the recommended sampling interval for all conventional heavy-duty coolant/antifreeze.The Level 2 Coolant Analysis should be performed if a problem is suspected or identified.

Table 1

Recommended Interval

Type of Coolant Level 1 Level 2

Cat DEAC

and Conventional Heavy-Duty Coolants Every 250 hours Yearly

Cat ELC

and Commercial EC-1 coolants Optional or every 500 hours Yearly or every 500 hours Note: Check the SCA (Supplemental Coolant Additive) of the conventional coolant at every oil change or at every 250 hours. Perform this check at the interval that occurs first.Refer to your machine OMM for recommendations specific to your machine.S O S Services Coolant Analysis (Level 1)

A coolant analysis (Level 1) is a test of the properties of the coolant.The following properties of the coolant are tested:

Glycol concentration for freeze protection and boil protection

Ability to protect from erosion and corrosion

pH

Conductivity

Visual analysis

Odor analysisThe results are reported, and appropriate recommendations are made.S O S Services Coolant Analysis (Level 2)

A coolant analysis ( Level 2) is a comprehensive chemical evaluation of the coolant. This analysis is also a check of the overall condition of the cooling system.The S O S coolant analysis ( Level 2) has the following features:

Full coolant analysis (Level 1)

Identification of metal corrosion and of contaminants

Identification of buildup of the impurities that cause corrosion

Identification of buildup of the impurities that cause scaling

Determination of the possibility of electrolysis within the cooling system of the engineThe results are reported, and appropriate recommendations are made.For more information on S O S coolant analysis, consult your Caterpillar dealer.

Have questions with 101602-1460?

Group cross 101602-1460 ZEXEL

Mitsubishi

Mitsubishi

101602-1460

INJECTION-PUMP ASSEMBLY