Information injection-pump assembly

BOSCH

9 400 614 704

9400614704

ZEXEL

101602-0700

1016020700

ISUZU

1156010333

1156010333

Rating:

Service parts 101602-0700 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

5-15300-089-1

12.

Open Pre:MPa(Kqf/cm2)

18.1{185}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 614 704

9400614704

ZEXEL

101602-0700

1016020700

ISUZU

1156010333

1156010333

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

2.4

2.35

2.45

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

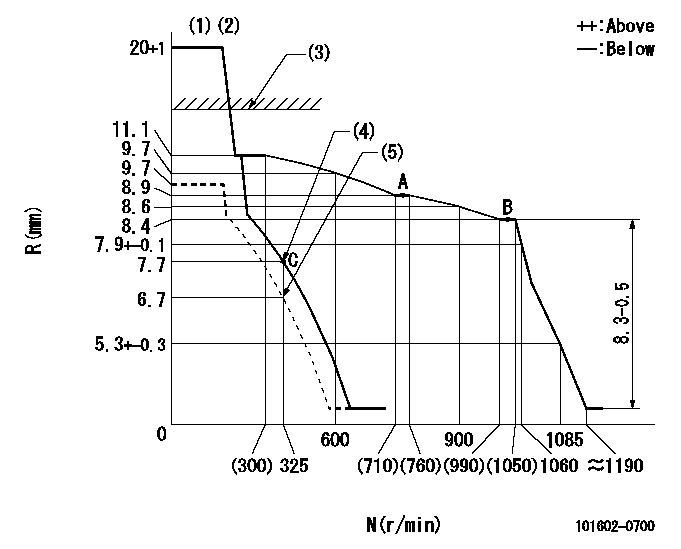

Injection quantity adjustment

Adjusting point

A

Rack position

8.9

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

33.2

31.7

34.7

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

8.4

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

32.8

31

34.6

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

7.7+-0.5

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

12.4

11.1

13.7

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK CAP: R1

(4)Main spring setting

(5)Set idle sub-spring

----------

K=16 R1=(17.5)mm

----------

----------

K=16 R1=(17.5)mm

----------

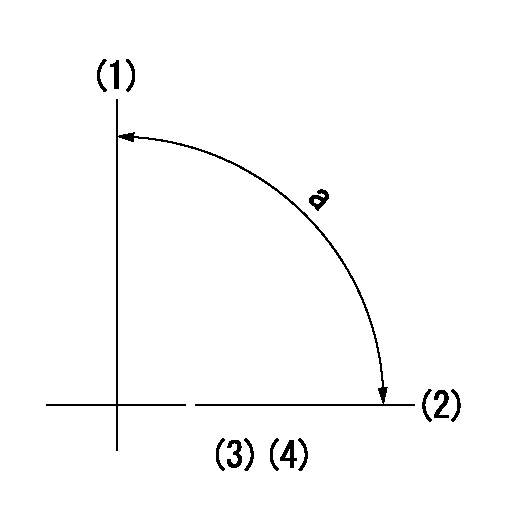

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=13.5deg+-5deg b=32deg+-5deg

----------

----------

a=13.5deg+-5deg b=32deg+-5deg

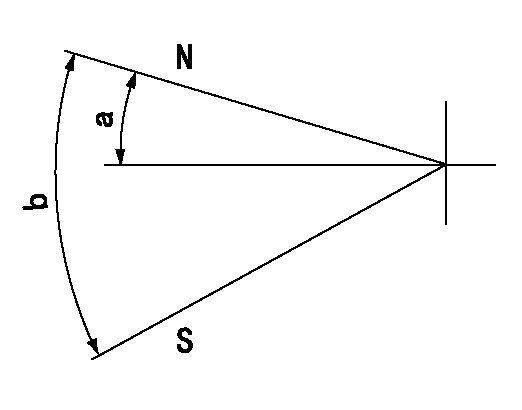

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=12deg+-5deg b=46deg+-5deg

----------

----------

a=12deg+-5deg b=46deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'CC' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=20deg

----------

a=(90deg)

----------

aa=20deg

----------

a=(90deg)

Information:

Control System PLC Outputs Hardwired to Relay Logic (Not Available to Customer)

Table 10

ISA TAG # PLC CARD # OUTPUT DESCRIPTION PLC REG ASSIGN SIGNAL TYPE ALARM SHUT DOWN TRIP / ACTIVATION CONDITION COMMENTS

YC-001 PLC07 Air Start to Engine O:7.0/03 DIGITAL Remote Start Only

YC-002 PLC07 Fuel Shutoff Signal to Engine O:7.0/00 DIGITAL X Shutdown or Fuel Off RFCR Relay

YC-015 PLC07 Air Shutoff Signal to Engine O:7.0/02 DIGITAL Overspeed and E-Stop ASOS Solenoid

YC-003 PLC07 Engine Prelube Signal to Engine O:7.0/01 DIGITAL >

9 kPa (1.3 psi) RPR Relay

YC-008 PLC07 Engine Protection System Override Relay On I:2.0/07 DIGITAL ROVR Relay - Override Shutdowns

YC-009 PLC07 Summary Group Alarm Relay Active O:7.0/05 DIGITAL X Any Alarm RSA Relay

YC-010 PLC07 Summary group Shutdown Signal O:7.0/07 DIGITAL X Protective Shutdown Energizes REFR Relay on Protective Shutdown

LY-001 PLC02 Jacket Water Detection Relay I:2.0/12 DIGITAL X RJWDA Relay Control System Lights and Meters

Table 11

ISA TAG # PLC CARD # OUTPUT DESCRIPTION PLC REG ASSIGN SIGNAL TYPE ALARM SHUT DOWN TRIP / ACTIVATION CONDITION COMMENTS

SI-004 Engine Speed Tachometer FREQ Mag Piclup Driven

SS1-001 Engine Hour Meter DIGITAL

PI-023 Starting Air Pressure Meter OHMS Resistive Sensor

YAL-009 PLC07 Summary Alarm Light O:7.0/06 DIGITAL X Any Alarm

YAL-010 PLC07 Summary Shutdown Light O:7.0/07 DIGITAL X Protective Shutdown

YAL-015 PLC07 PLC Failure O:7.0/15 DIGITAL X No Signal to RPLCFA RPLCFA De-energized on PLC Failure

PIL-008 Engine Prelubed DIGITAL >

9 kPa (1.3 psi)

Table 10

ISA TAG # PLC CARD # OUTPUT DESCRIPTION PLC REG ASSIGN SIGNAL TYPE ALARM SHUT DOWN TRIP / ACTIVATION CONDITION COMMENTS

YC-001 PLC07 Air Start to Engine O:7.0/03 DIGITAL Remote Start Only

YC-002 PLC07 Fuel Shutoff Signal to Engine O:7.0/00 DIGITAL X Shutdown or Fuel Off RFCR Relay

YC-015 PLC07 Air Shutoff Signal to Engine O:7.0/02 DIGITAL Overspeed and E-Stop ASOS Solenoid

YC-003 PLC07 Engine Prelube Signal to Engine O:7.0/01 DIGITAL >

9 kPa (1.3 psi) RPR Relay

YC-008 PLC07 Engine Protection System Override Relay On I:2.0/07 DIGITAL ROVR Relay - Override Shutdowns

YC-009 PLC07 Summary Group Alarm Relay Active O:7.0/05 DIGITAL X Any Alarm RSA Relay

YC-010 PLC07 Summary group Shutdown Signal O:7.0/07 DIGITAL X Protective Shutdown Energizes REFR Relay on Protective Shutdown

LY-001 PLC02 Jacket Water Detection Relay I:2.0/12 DIGITAL X RJWDA Relay Control System Lights and Meters

Table 11

ISA TAG # PLC CARD # OUTPUT DESCRIPTION PLC REG ASSIGN SIGNAL TYPE ALARM SHUT DOWN TRIP / ACTIVATION CONDITION COMMENTS

SI-004 Engine Speed Tachometer FREQ Mag Piclup Driven

SS1-001 Engine Hour Meter DIGITAL

PI-023 Starting Air Pressure Meter OHMS Resistive Sensor

YAL-009 PLC07 Summary Alarm Light O:7.0/06 DIGITAL X Any Alarm

YAL-010 PLC07 Summary Shutdown Light O:7.0/07 DIGITAL X Protective Shutdown

YAL-015 PLC07 PLC Failure O:7.0/15 DIGITAL X No Signal to RPLCFA RPLCFA De-energized on PLC Failure

PIL-008 Engine Prelubed DIGITAL >

9 kPa (1.3 psi)