Information injection-pump assembly

BOSCH

9 400 610 293

9400610293

ZEXEL

101601-9922

1016019922

Rating:

Service parts 101601-9922 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 610 293

9400610293

ZEXEL

101601-9922

1016019922

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.3

3.25

3.35

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.9

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

73.5

71.5

75.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

9.9+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

10.5

9

12

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

74.5

74.5

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Timer adjustment

Pump speed

r/min

550--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

500

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1000

Advance angle

deg.

3.2

2.7

3.7

Timer adjustment_04

Pump speed

r/min

1500

Advance angle

deg.

6.5

6

7

Remarks

Finish

Finish

Test data Ex:

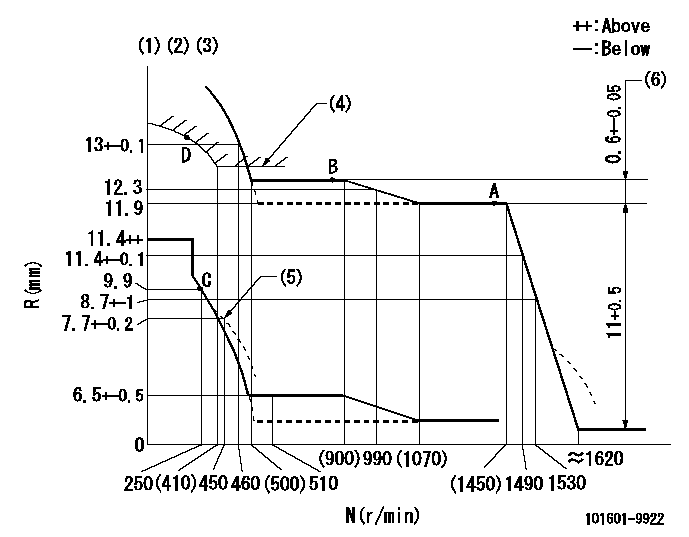

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Tolerance for racks not indicated: +-0.05mm.

(4)Excess fuel setting for starting: SXL (N = N1)

(5)Damper spring setting

(6)Rack difference between N = N2 and N = N3

----------

RT=1 TH=2.4mm SXL=12.6+0.2mm N1=450r/min N2=1450r/min N3=900r/min

----------

----------

RT=1 TH=2.4mm SXL=12.6+0.2mm N1=450r/min N2=1450r/min N3=900r/min

----------

Speed control lever angle

F:Full speed

----------

----------

a=10deg+-5deg

----------

----------

a=10deg+-5deg

0000000901

F:Full load

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=55mm

----------

a=5.5deg+-5deg b=22deg+-3deg

----------

aa=55mm

----------

a=5.5deg+-5deg b=22deg+-3deg

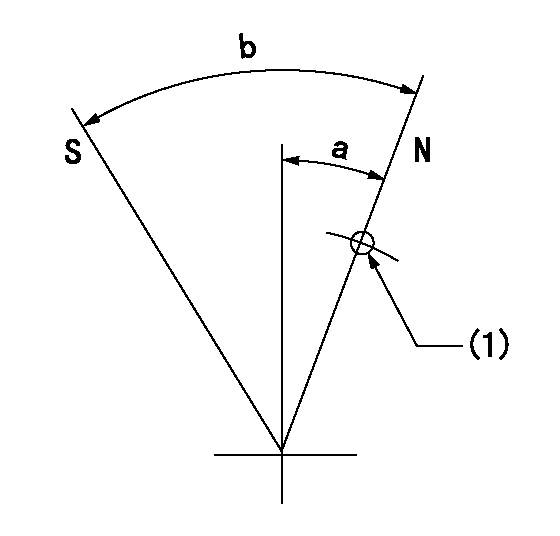

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

----------

aa=30mm

----------

a=35deg+-5deg b=71deg+-5deg

----------

aa=30mm

----------

a=35deg+-5deg b=71deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position for the No. 6 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(30deg)

----------

----------

a=(30deg)

Information:

TECHNICAL INFORMATION BULLETIN June 16, 2004

Truck Engines

C7 (KAL)

C9 (9DG)

C-9 (MTB)

Component Code: 1290SUBJECT: Injector Misfire due to Low/No Fuel Condition

PROBLEM:

Analysis of injectors returned from the field indicates that running the engine out of fuel, excessive air in the fuel, or high fuel inlet restriction may cause an internal injector failure. Multiple injectors failing the Cylinder Cutout Test in Caterpillar Electronic Technician (Cat ET) may indicate this mode of failure. If this occurs, debris from the internal injector failure may collect in the fuel return pressure regulator or fuel return screen (if equipped). See Figure 1.

SOLUTION:

If the Cylinder Cutout Test in Cat ET indicates that multiple injectors have failed, or if the engine has a recent history of injector failures, the fuel return pressure regulator and the fuel return screen need to be inspected for debris. See Figure 1.

Clean the fuel return screen (if equipped). If the engine is equipped with a fuel regulator that has a 90-degree elbow on the cylinder head, then there is a screen inside of the elbow. Remove the 90-degree elbow from the cylinder head and pressure regulator assembly. See Figure 1. Reverse flush any debris out of the elbow screen. If all of the debris cannot be removed from the elbow screen, then replace the 196-6838 90-degree elbow.

Clean/Replace the fuel return pressure regulator assembly as required. If the engine is equipped with a 90-degree elbow screen (see Step 2), the debris should have been caught by the screen. Only replace the 229-8870 pressure regulator if debris is visible on the inlet side of the pressure regulator. Replace failed injectors as indicated by the Cat ET Cylinder Cutout Test.

If the engine did not run out of fuel, make sure that the fuel inlet restriction measured at the fuel transfer pump inlet is within specification (max inlet restriction 4.1 in Hg or 14 kPa). Also, make sure that there is not excessive air in the fuel system by using a sight gauge on the fuel inlet and fuel outlet of the cylinder head. Make sure the fuel tank vent or cap is venting properly.

Note: There have been documented cases of pinched/restricted Original Equipment Manufacturer (OEM) fuel lines and air entry on OEM primary fuel filters.

If the fuel return pressure regulator or the elbow are replaced, return them to the Caterpillar claims room at the address below.

Caterpillar Service Claims Room 8201 N. University Peoria, IL 61615 USA Attn: Geoff Monari / Anant Kasture

Please share this information with your TEPS dealers.

Figure 1

COPYRIGHT 2004 CATERPILLAR

ALL RIGHTS RESERVED