Information injection-pump assembly

ZEXEL

101601-9481

1016019481

Rating:

Service parts 101601-9481 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Cross reference number

ZEXEL

101601-9481

1016019481

Zexel num

Bosch num

Firm num

Name

101601-9481

INJECTION-PUMP ASSEMBLY

SX6130 *

SX6130 *

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

1.75

1.7

1.8

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

R1(10.3)

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

126

124

128

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.2+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

15

13.5

16.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

140

140

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Timer adjustment

Pump speed

r/min

450--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

400

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

700

Advance angle

deg.

2.2

1.7

2.7

Timer adjustment_04

Pump speed

r/min

1000

Advance angle

deg.

6

5.5

6.5

Remarks

Finish

Finish

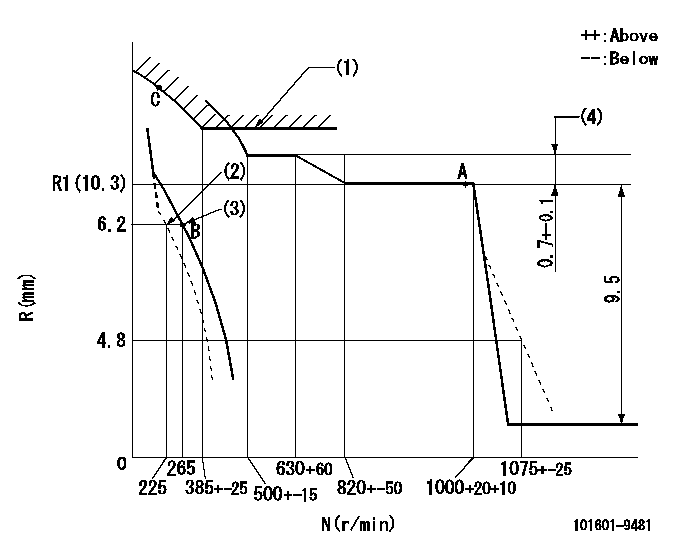

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Excess fuel setting for starting: SXL

(2)Damper spring setting

(3)Set the main spring and the damper spring.

(4)Rack difference between N = N1 and N = N2

----------

SXL=(R1+0.8)+0.2mm N1=1000r/min N2=600r/min

----------

----------

SXL=(R1+0.8)+0.2mm N1=1000r/min N2=600r/min

----------

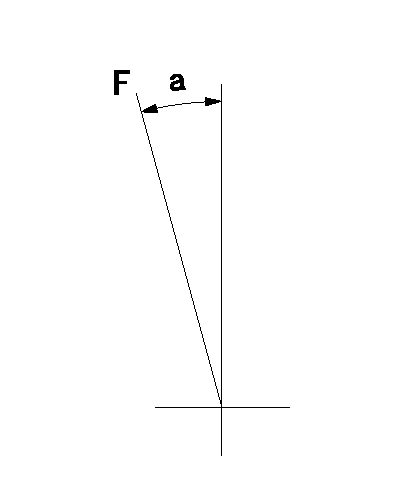

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=5deg+-5deg b=(19deg)+-5deg

----------

----------

a=5deg+-5deg b=(19deg)+-5deg

0000000901

F:Full load

----------

----------

a=20deg+-5deg

----------

----------

a=20deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=36deg+-5deg b=71deg+-5deg

----------

----------

a=36deg+-5deg b=71deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(40deg)

----------

----------

a=(40deg)

Information:

Possible Causes/Corrections Air Or Water In Fuel SystemWith air in the fuel system, the engine will normally be difficult to start, run rough, and release a large amount of white smoke. If the engine will not start, loosen a fuel injection line nut at the through the head adapter and crank the engine until fuel comes out. Tighten the fuel line nut. Start the engine. If the engine does not run smooth or releases a large amount of white smoke, loosen the fuel line nuts one at a time at the through the head adapters until the fuel that comes out is free of air. Tighten the fuel line nuts. If the air cannot be removed in this way, put 35 kPa (5 psi) of air pressure to the fuel tank.

Do not use more than 55 kPa (8 psi) of air pressure in the fuel tank or damage to the tank may result.

Check for leaks at the connection between the fuel tank and the fuel transfer pump. If leaks are found, tighten the connections or replace the lines. If there are no visual leaks, remove the fuel supply line from the tank and connect it to an outside furl supply. If this corrects the problem, the suction line (standpipe) inside the fuel tank has a leak.Water in the fuel can cause rough running and possible fuel system damage. Valve Adjustment Not CorrectCheck and make necessary adjustments as in Testing And Adjusting Section of the Service Manual. Intake valve lash is 0.38 mm (.015 in) and exhaust valve lash is 0.64 mm (.025 in). Also check for a bent or broken push rod. Defective Fuel Nozzle(s)Find a defective nozzle by running engine at the rpm where it runs rough. Loosen the fuel line nut at the through the head adapter enough to stop fuel supply to that cylinder. Each cylinder must be checked this way. If a cylinder is found where loosening of the nut makes no difference in the rough running, test the nozzle for that cylinder. To test a nozzle, remove the nozzle from the engine and test as in Testing and Adjusting Section of this Service Manual. Fuel Leakage From Fuel Injection Line NutTighten nut to 40 7 N m (30 5 lb ft). Again check for leakage. Be sure to check fuel injection lines inside valve cover base. Defective Fuel Injection PumpAn injection pump can have a good fuel flow coming from it but cause rough running because of slow timing that is caused by wear on the bottom end of the plunger. See the Testing and Adjusting Section in this Service Manual for the correct specifications and procedure to check plungers and lifters.Fuel pumps which are severely scored from debris can cause rough running but fuel dilution usually occurs before horsepower is affected.Low installation torque on the fuel pump retaining nut can cause misfire, rough running and low power. Fuel Has A High "Cloud Point"In cold weather operation this condition should

Do not use more than 55 kPa (8 psi) of air pressure in the fuel tank or damage to the tank may result.

Check for leaks at the connection between the fuel tank and the fuel transfer pump. If leaks are found, tighten the connections or replace the lines. If there are no visual leaks, remove the fuel supply line from the tank and connect it to an outside furl supply. If this corrects the problem, the suction line (standpipe) inside the fuel tank has a leak.Water in the fuel can cause rough running and possible fuel system damage. Valve Adjustment Not CorrectCheck and make necessary adjustments as in Testing And Adjusting Section of the Service Manual. Intake valve lash is 0.38 mm (.015 in) and exhaust valve lash is 0.64 mm (.025 in). Also check for a bent or broken push rod. Defective Fuel Nozzle(s)Find a defective nozzle by running engine at the rpm where it runs rough. Loosen the fuel line nut at the through the head adapter enough to stop fuel supply to that cylinder. Each cylinder must be checked this way. If a cylinder is found where loosening of the nut makes no difference in the rough running, test the nozzle for that cylinder. To test a nozzle, remove the nozzle from the engine and test as in Testing and Adjusting Section of this Service Manual. Fuel Leakage From Fuel Injection Line NutTighten nut to 40 7 N m (30 5 lb ft). Again check for leakage. Be sure to check fuel injection lines inside valve cover base. Defective Fuel Injection PumpAn injection pump can have a good fuel flow coming from it but cause rough running because of slow timing that is caused by wear on the bottom end of the plunger. See the Testing and Adjusting Section in this Service Manual for the correct specifications and procedure to check plungers and lifters.Fuel pumps which are severely scored from debris can cause rough running but fuel dilution usually occurs before horsepower is affected.Low installation torque on the fuel pump retaining nut can cause misfire, rough running and low power. Fuel Has A High "Cloud Point"In cold weather operation this condition should

Have questions with 101601-9481?

Group cross 101601-9481 ZEXEL

Nissan-Diesel

101601-9481

INJECTION-PUMP ASSEMBLY

SX6130

SX6130