Information injection-pump assembly

ZEXEL

101601-9430

1016019430

Rating:

Cross reference number

ZEXEL

101601-9430

1016019430

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3

2.95

3.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

51.4

49.8

53

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.5+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

8.2

6.4

10

Max. variation between cylinders

%

0

-12

12

Fixing the rack

*

Timer adjustment

Pump speed

r/min

1280--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1230

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1350

Advance angle

deg.

1.5

1

2

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

4

4

4

Remarks

Finish

Finish

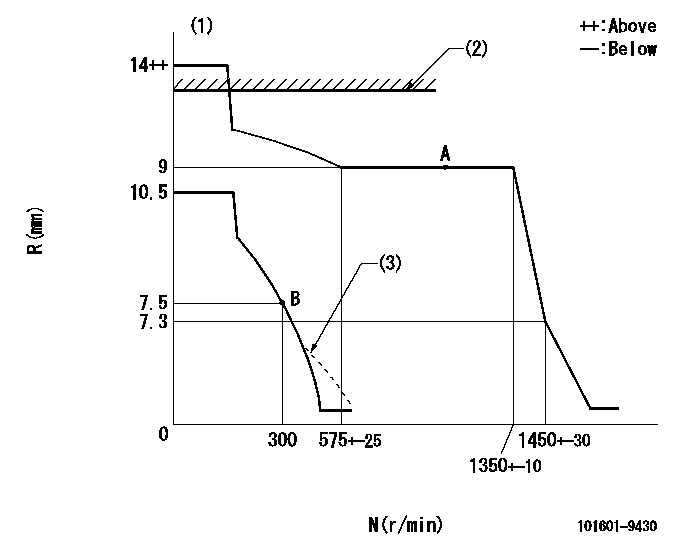

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT: RAL

(3)Damper spring setting: DL

----------

K=20 RAL=12+0.2mm DL=7-0.2mm

----------

----------

K=20 RAL=12+0.2mm DL=7-0.2mm

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=24deg+-5deg b=26deg+-5deg

----------

----------

a=24deg+-5deg b=26deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=10.5deg+-5deg b=53deg+-5deg

----------

----------

a=10.5deg+-5deg b=53deg+-5deg

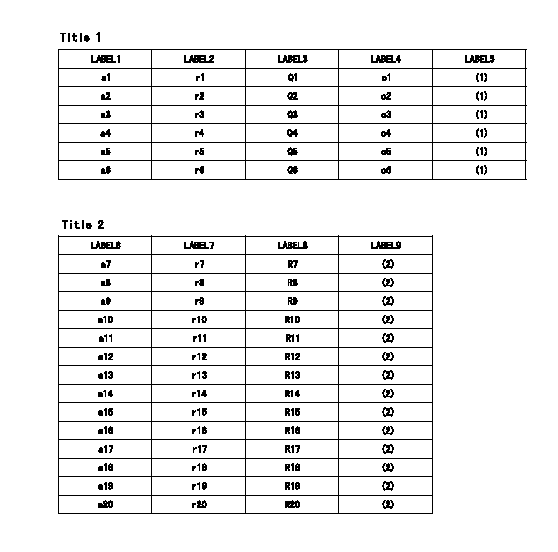

0000001501 GOV FULL LOAD ADJUSTMENT

Title1:Full load stopper adjustment

Title2:Governor set speed

LABEL1:Distinguishing

LABEL2:Pump speed (r/min)

LABEL3:Ave. injection quantity (mm3/st)

LABEL4:Max. var. bet. cyl.

LABEL5:Remarks

LABEL6:Distinguishing

LABEL7:Governor set speed (r/min)

LABEL8:Maximum no-load speed (r/min)

LABEL9:Remarks

(1)Adjustment conditions are the same as those for measuring injection quantity.

(2)At high idle rack position L

----------

L=7.3mm

----------

a1=A a2=B a3=- a4=- a5=- a6=- r1=900r/min r2=900r/min r3=- r4=- r5=- r6=- Q1=54.7+-1.6mm3/st Q2=51.4+-1.6mm3/st Q3=- Q4=- Q5=- Q6=- c1=+-2% c2=+-2% c3=- c4=- c5=- c6=- a7=27 a8=26 a9=25 a10=24 a11=23 a12=22 a13=21 a14=20 a15=19 a16=18 a17=17 a18=16 a19=15 a20=14 r7=1350r/min r8=1300r/min r9=1250r/min r10=1200r/min r11=1150r/min r12=1100r/min r13=1050r/min r14=1000r/min r15=950r/min r16=900r/min r17=850r/min r18=800r/min r19=750r/min r20=700r/min R7=1450+-33r/min R8=1395+-32r/min R9=1340+-31r/min R10=1290+-30r/min R11=1235+-28r/min R12=1180+-27r/min R13=1130+-26r/min R14=1075+-25r/min R15=1020+-23r/min R16=965+-22r/min R17=915+-22r/min R18=860+-20r/min R19=805+-18r/min R20=750+-17r/min

----------

L=7.3mm

----------

a1=A a2=B a3=- a4=- a5=- a6=- r1=900r/min r2=900r/min r3=- r4=- r5=- r6=- Q1=54.7+-1.6mm3/st Q2=51.4+-1.6mm3/st Q3=- Q4=- Q5=- Q6=- c1=+-2% c2=+-2% c3=- c4=- c5=- c6=- a7=27 a8=26 a9=25 a10=24 a11=23 a12=22 a13=21 a14=20 a15=19 a16=18 a17=17 a18=16 a19=15 a20=14 r7=1350r/min r8=1300r/min r9=1250r/min r10=1200r/min r11=1150r/min r12=1100r/min r13=1050r/min r14=1000r/min r15=950r/min r16=900r/min r17=850r/min r18=800r/min r19=750r/min r20=700r/min R7=1450+-33r/min R8=1395+-32r/min R9=1340+-31r/min R10=1290+-30r/min R11=1235+-28r/min R12=1180+-27r/min R13=1130+-26r/min R14=1075+-25r/min R15=1020+-23r/min R16=965+-22r/min R17=915+-22r/min R18=860+-20r/min R19=805+-18r/min R20=750+-17r/min

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(30deg)

----------

----------

a=(30deg)

Information:

Introduction

The problem that is identified below does not have a known permanent solution. Until a known permanent solution is known, use the solution that is identified below.Problem

Multiple dealers have found that the "ARD Nozzle Heater Circuit Test" in Cat ET does not work after flashing to PROD 5 engine software. An error message is returned that says calibration unsuccessful when the start button is pressed. Refer to the Illustration below.

Illustration 1 g02839458

Illustration 2 g02839481

Solution

The "ARD Nozzle Heater Circuit Test" is still functional despite the error being shown. An engine software solution for this issue is in process and should be released soon.The test should be working while the calibration error is present as long as the appropriate conditions are met to run the test. Once finished troubleshooting, the technician should select "Finish" to end the circuit test.

The problem that is identified below does not have a known permanent solution. Until a known permanent solution is known, use the solution that is identified below.Problem

Multiple dealers have found that the "ARD Nozzle Heater Circuit Test" in Cat ET does not work after flashing to PROD 5 engine software. An error message is returned that says calibration unsuccessful when the start button is pressed. Refer to the Illustration below.

Illustration 1 g02839458

Illustration 2 g02839481

Solution

The "ARD Nozzle Heater Circuit Test" is still functional despite the error being shown. An engine software solution for this issue is in process and should be released soon.The test should be working while the calibration error is present as long as the appropriate conditions are met to run the test. Once finished troubleshooting, the technician should select "Finish" to end the circuit test.